Intelligent drainage slag system for coal mine gas extraction downhole drilling and application thereof

A coal mine gas and intelligent drainage technology, which is applied in the direction of gas discharge, drainage, mining equipment, etc., can solve the problem of low drainage concentration, achieve the goal of solving low drainage concentration, increasing the amount of gas drainage, and improving the efficiency of gas drainage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

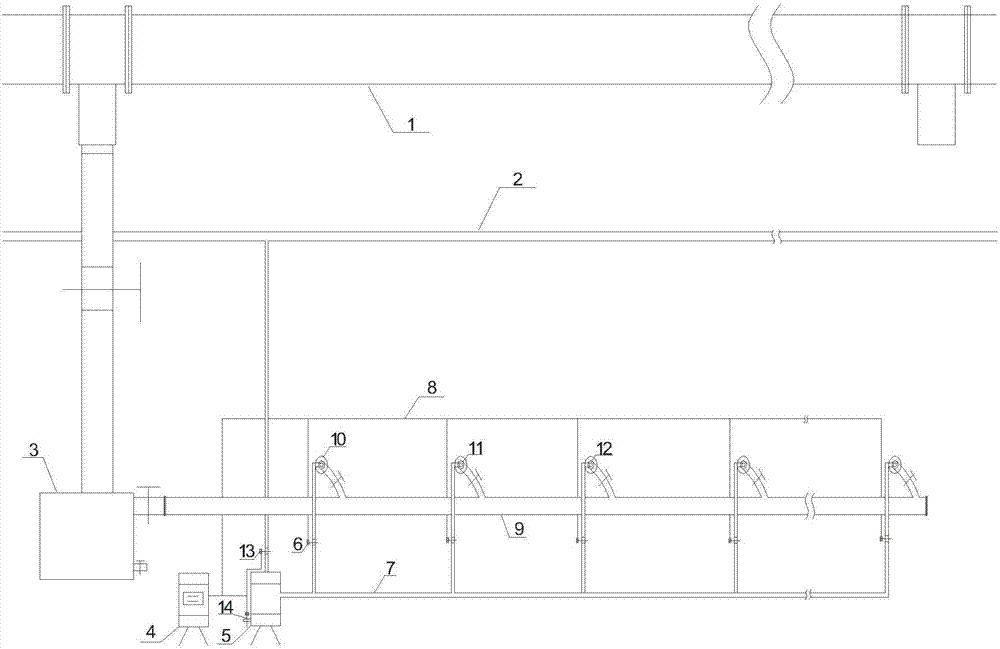

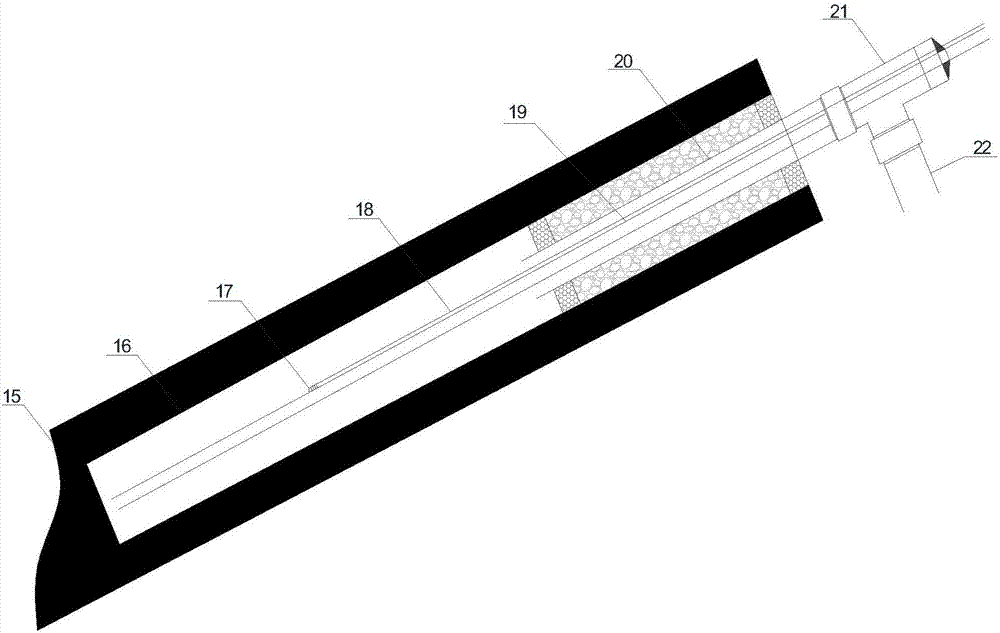

[0023] Such as figure 1 The schematic diagram of the downward drilling multi-hole parallel drainage and slag discharge provided by the present invention is shown. The coal mine gas drainage downward drilling intelligent drainage and slagging system includes a mining PLC control box 4 and a mine pneumatic pumping and drainage pump 5, which are respectively placed underground. Near the drainage borehole; the mine electric valve 6 is installed on the downward borehole drainage pipeline outside the borehole, and the mine PLC control box controls the mine electric valve 6 through the PLC control program to control the opening and closing of the borehole drainage pipe. The electric valve 13 of the control pump is installed on the intake end pipeline of the mining drainage pump, and the drainage pipeline 19 is placed in the borehole, and is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com