A 3D Simulation Calculation Method for Nonlinear Characteristics of Fuel Assembly Compression System

A non-linear feature, fuel assembly technology, used in design optimization/simulation, special data processing applications, etc., can solve the problems of inaccurate load calculation of the compaction system, and failure to consider the critical radiation effect, etc., to reduce Failure risk, achieve accurate calculation, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

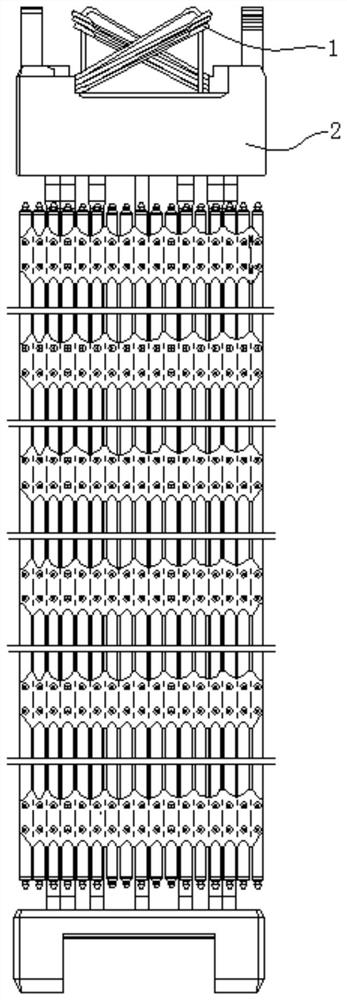

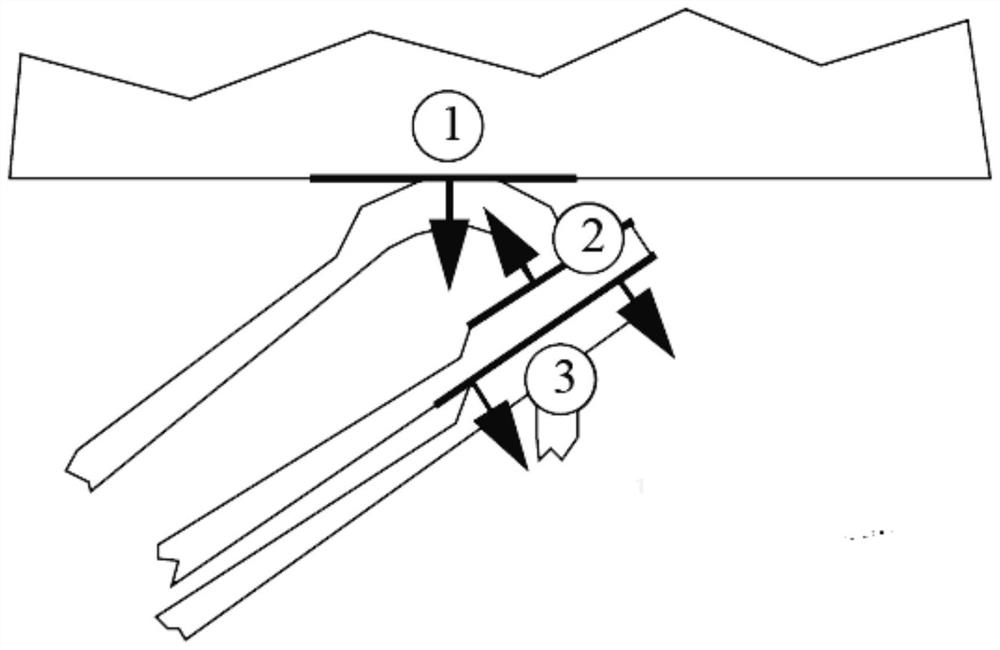

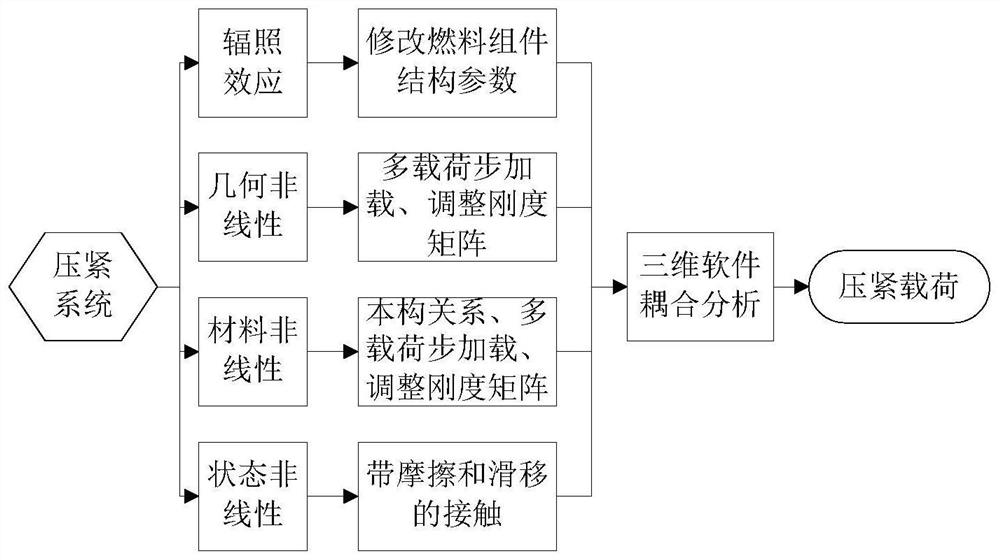

[0039] A three-dimensional simulation calculation method for the nonlinear characteristics of the fuel assembly compaction system, based on the commercial software ANSYS, specifically for figure 1 The plate spring compression system shown, its calculation process is as follows image 3 shown, including:

[0040] 1) Simulation of irradiation growth

[0041] The macroscopic experimental model of fuel assembly irradiation growth rate and fast neutron fluence is shown in formula (1), and the fast neutron fluence at the position of the fuel assembly compression system at the corresponding burnup time obtained by combining with the reactor physical design calculation The irradiation growth rate of the fuel assembly can be obtained. Then, according to formula (2), the influence of radiation growth on the deformation of the compaction system is obtained, that is, the simulation of radiation growth of fuel assemblies is realized.

[0042]

[0043] In the formula, a, b, c and d a...

Embodiment 2

[0067] The only difference between this embodiment and Embodiment 1 is that the simulation of the radiation relaxation of the fuel assembly pressing system is realized by modifying the constitutive relation of the material, such as Figure 4 , that is, the stress σ is the strain ε, the fast neutron fluence and the function of fast neutron energy E:

[0068]

[0069] in,

[0070] σ 0 =f(ε) (6)

[0071]

[0072] In the formula, σ 0 In order to consider the stress after radiation relaxation, ε is the strain, and f(ε) is not affected by radiation relaxation, the same as in the embodiment 1 ; σ is the stress after radiation relaxation is taken into account; j is the number of fast neutron groups subjected to the compaction system; is the i-th fast neutron fluence received by the compaction system; E i is the average energy of group i fast neutrons received by the compaction system; G1, G2, G3, G4 are radiation relaxation correlation coefficients. For this fuel assemb...

Embodiment 3

[0074] The difference between this embodiment and Embodiment 1 is that the only difference between this embodiment and Embodiment 1 and Embodiment 2 is that the calculated fuel assembly system can also adopt other spring structures other than the plate spring compression system, which can be a helical Spring compression system, disc spring compression system, torsion bar spring compression system, other spring compression systems or a compression system in which the aforementioned multiple springs are combined with each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com