Monitoring device, and garbage can management method and apparatus

A technology for monitoring equipment and trash cans, applied in trash cans, measuring devices, garbage collection, etc., can solve the problems of resource waste, cost increase, and inability to intelligently allocate, etc., and achieve the effect of reducing operating costs and restraining resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

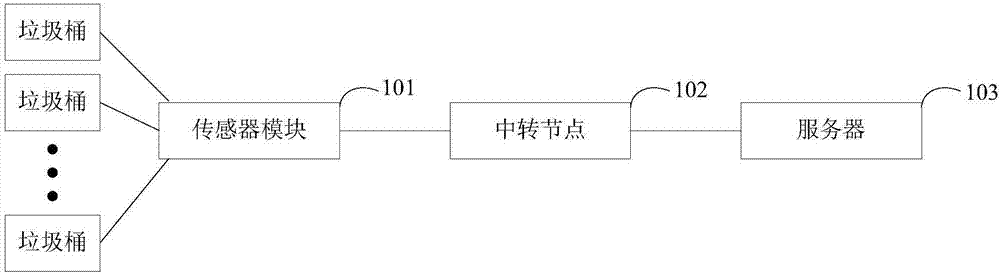

[0050] figure 1 A schematic block diagram of a monitoring device provided by Embodiment 1 of the present invention is shown, and for convenience of description, only parts related to this embodiment are shown.

[0051] Such as figure 1 As shown, the monitoring device includes a sensor module 101 , a transit node 102 and a server 103 .

[0052] The sensor module 101 is used to detect the garbage height in each garbage bin, and when the detected first garbage height does not change, the first garbage height is sent to the transfer node through the communication module, and the first garbage height is the Any one of the garbage heights in the garbage bins detected by the sensor module.

[0053] Here, one or more sensors may be included in the sensor module 101. The number and types of sensors are determined according to actual needs. For example, sensors are respectively arranged at different heights from the bottom on the inner wall of each trash can. The types of sensors can ...

Embodiment 2

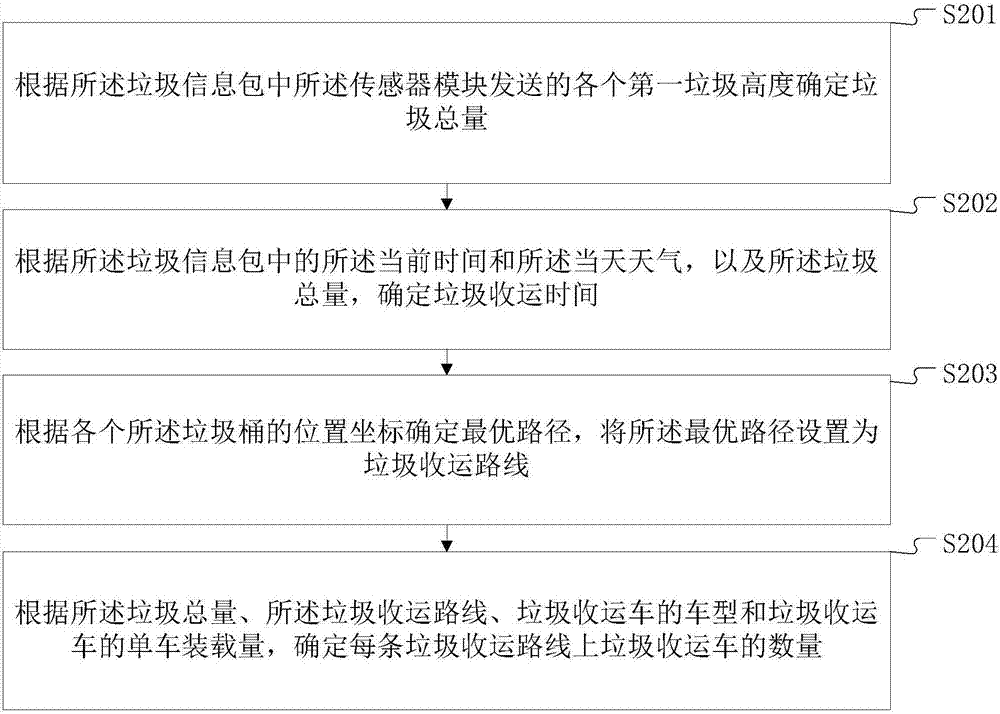

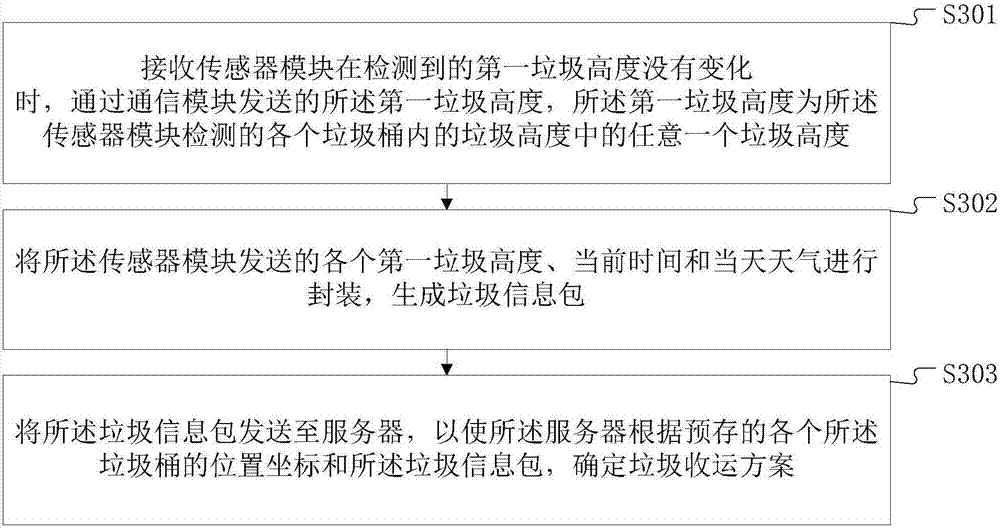

[0093] image 3 The implementation flow of the garbage bin management method provided by the second embodiment of the present invention is shown. In this embodiment, the processing process of the transfer node is taken as an example for description. As shown in the figure, the method may include the following steps:

[0094] Step S301, receiving the first garbage height sent by the communication module when the first garbage height detected by the sensor module does not change, the first garbage height is the garbage height in each garbage bin detected by the sensor module Any one of the garbage heights in .

[0095] Here, the sensor module may include one or more sensors, and the number and types of sensors are determined according to actual needs.

[0096] The sensor module can detect the height of the garbage in the garbage bin in real time 24 hours a day, or detect the height of the garbage every preset time, or preset the time period of garbage height detection, for exa...

Embodiment 3

[0126] In order to better understand the above method, an application example of the garbage bin management method of the present invention is described in detail below. In this embodiment, the interaction process between the sensor module, the transfer node and the server is used as an example for illustration. This description It is not intended to limit the solution of the present invention.

[0127] Such as Figure 4 As shown, this application example may include:

[0128] Step S401, the transit node sends a first opening command to the first sensor unit in the sensor module at a preset opening time.

[0129] Here, the sensor module includes a first sensor unit, a second sensor unit and a third sensor unit, the first sensor unit includes sensors respectively arranged at the first preset positions of each garbage can, and the second sensor unit includes sensors respectively arranged at the first preset positions of each garbage bin. The sensor at the second preset positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com