Cavity cleaning method for reducing lower electrode damage

A technology of electrodes and chambers, which is applied in the field of chamber cleaning to reduce the damage of the lower electrodes, can solve the problems of occupying equipment transmission resources, reducing production efficiency, increasing wafer consumption, etc., so as to prolong the service life, avoid damage to the lower electrodes, and save energy. Effect of Wafer Consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

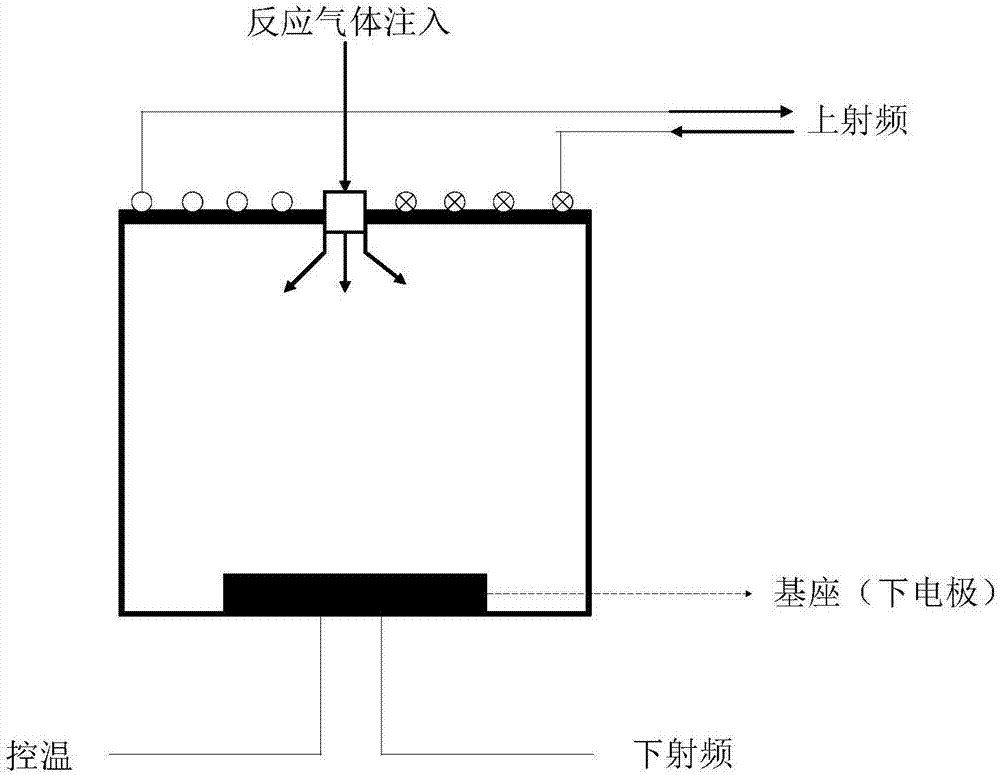

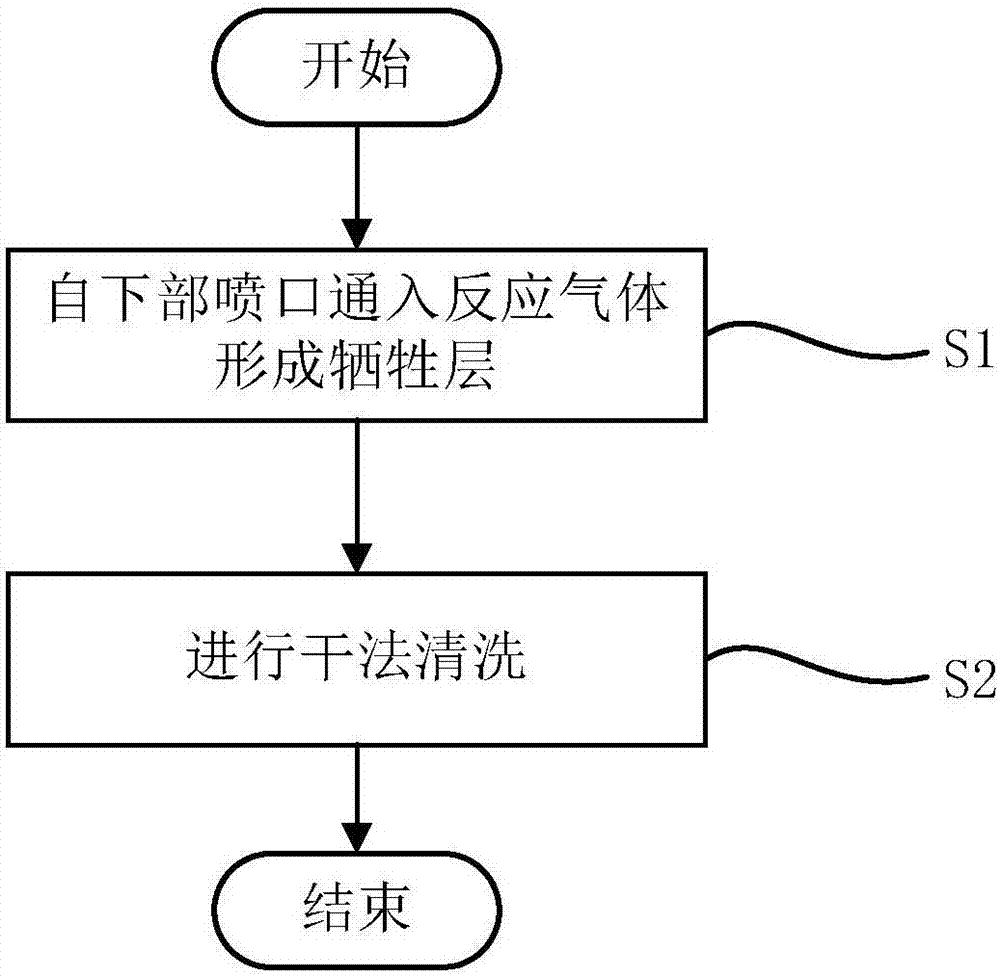

[0032] The inductively coupled plasma etching machine is used to etch silicon deeply, and the process gas for etching silicon grooves is the well-known SF 6 and C 4 f 8 , during the etching process, the C produced by physical bombardment of Si and photoresist will be deposited on the wall of the ICP etching chamber. x h yWait. Chamber cleaning is performed between each wafer to reduce damage to the bottom electrode.

[0033] In the sacrificial layer forming step S1, the power of the upper electrode is turned off, the power of the lower electrode is set between 50W and 500W, the pressure of the chamber is set between 3mT and 100mT, and the C 4 f 8 Gas, the gas flow rate is 20sccm~200sccm, the feeding time is 3s~20s, and 10nm~100nm of C is deposited on the surface of the lower electrode. x f y as a sacrificial layer. The reaction gas is introduced from the lower nozzle and the power of the lower electrode is started, so that C x f y concentrated deposition on the surfa...

Embodiment 2

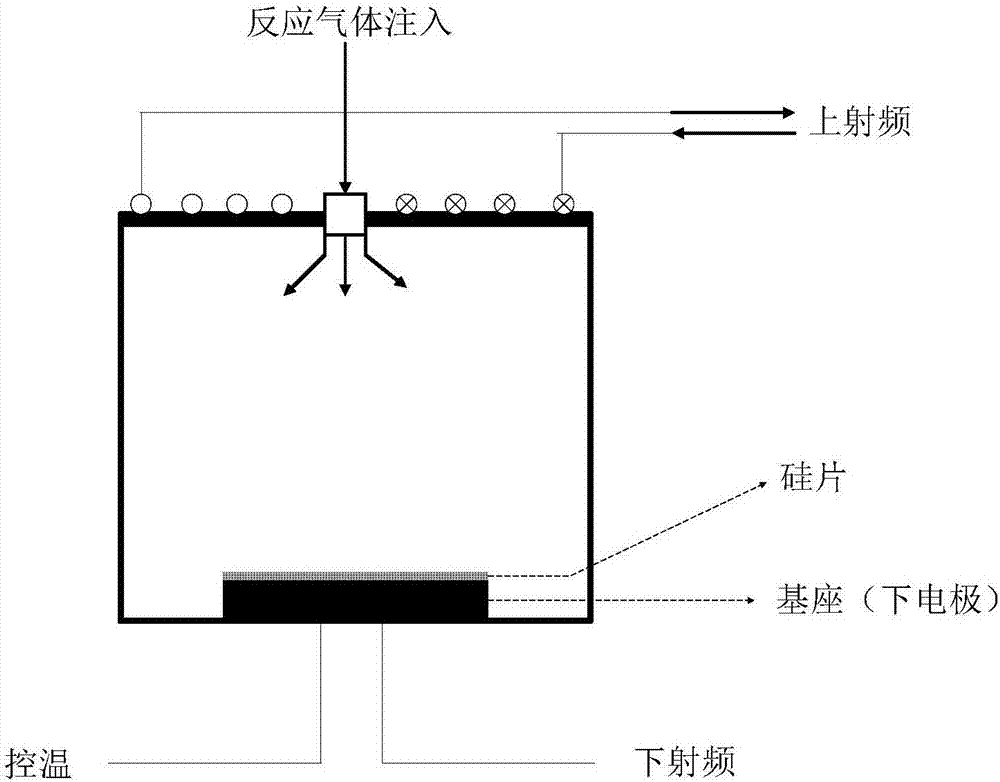

[0036] Silicon is etched using an inductively coupled plasma etching machine, and the process gas for etching silicon is the well-known Cl 2 / HBr / O 2 , during the etching process, the Si produced by physical bombardment of Si and photoresist will be deposited on the wall of the etching chamber, C x h y And SiBr, which is not volatile under plasma reaction 4 , SiBr x o y , SiCl x o y Wait. Chamber cleaning is performed between each wafer to reduce damage to the bottom electrode.

[0037] In the sacrificial layer forming step S1, the power of the upper electrode is turned off, the power of the lower electrode is set between 100W and 500W, the chamber pressure is set between 3mT and 100mT, and SiH is injected through the lower nozzle 4 gas and NH 3 gas, where SiH 4 The flow rate is 20sccm~200sccm, NH 3 The feed flow rate is 20sccm-200sccm, the feed time is 3s-20s, and 30-100nm of SiN is deposited on the surface of the lower electrode as a sacrificial layer. The reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com