Embedded multistage denitrification filter tank

A denitrification filter, embedded technology, used in anaerobic digestion treatment, chemical instruments and methods, water treatment parameter control and other directions, can solve the complex sewage impurities, can not meet the needs of development, and there is no reservation in wastewater treatment. It can solve the problems of processing capacity and space, so as to achieve the effect of strengthening denitrification and enhancing the purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

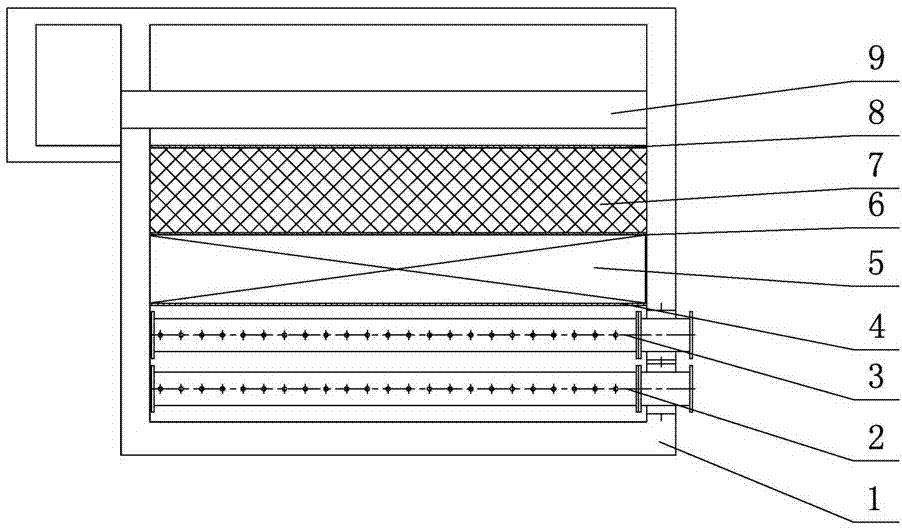

[0023] Example 1: If figure 1 As shown, a kind of embedded multistage denitrification filter that the present invention proposes, by concrete tank body 1, filter tank water distribution device 2, filter tank air distribution device 3, filter tank lower filter plate 4, filter material 5, filter tank The upper filter plate of the pool (or the lower grid plate of the anaerobic section) 6, the anaerobic biological carrier 7, the upper grid plate 8 of the anaerobic section and the water distribution tank 9 of the filter tank. Among them, the anaerobic biological carrier 7 can be used as a carrier for the attachment and reproduction of microorganisms in the water body, forming a layer of biofilm, which can quickly degrade excess TN, COD, and BOD in the water body 5 , NH 3 -N, TP and other pollutants; while the filter material 5 can effectively intercept suspended solids in water and sewage, further reduce SS, COD and other pollutants in the water body, and improve the sewage purifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com