Nickel-catalyzed n-alkylation to prepare secondary amines or n′-alkylhydrazides

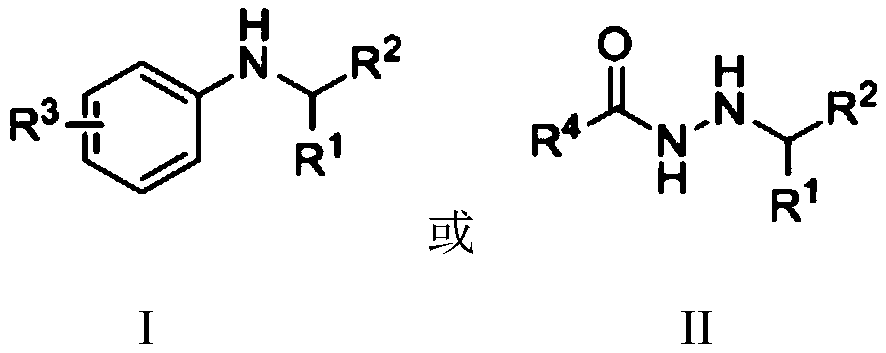

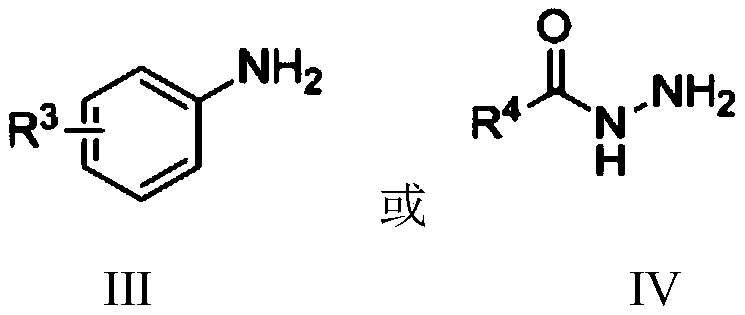

A technology of alkylation reaction and alkyl hydrazide, which is applied in the field of N-alkylation, can solve problems such as N'-alkylation of hydrazide compounds, save experimental steps and costs, and improve environmental friendliness performance, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

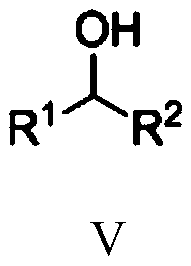

[0048] Embodiment 1: Preparation of N-phenyl-1-phenyl-1-ethylamine

[0049]

[0050] Under nitrogen protection, add Ni(OTf) into a 10mL Schlenk reaction tube 2 (2.9mg, 0.008mmol), 1,2-bis(dicyclohexylphosphine)ethane (4.3mg, 0.010mmol) and tert-amyl alcohol (1.2mL), stirred for 10 minutes, then added aniline (38mg, 0.4mmol) , 1-phenylethanol (98mg, 0.8mmol) and Molecular sieves (100 mg). The reaction tube was sealed and heated in an oil bath at 120°C for 24 hours. After the reaction stopped, it was cooled, and the reaction solution was directly added to a silica gel column, and eluted with petroleum ether and ethyl acetate (volume ratio 20:1) to obtain pure N-phenyl-1-phenyl-1-ethylamine, the yield 80%.

[0051] 1 H NMR (400MHz, CDCl 3 ):δ7.41-7.33(m,2H),7.30-7.26(m,2H),7.24-7.18(m,1H),7.12-7.00(m,2H),6.63(m,1H),6.55-6.42 (m,2H),4.47(q,J=6.7Hz,1H),4.00(br s,1H),1.50(d,J=6.7Hz,3H).

[0052] 13 C NMR (101MHz, CDCl 3 ): δ147.3, 145.2, 129.1, 128.6, 126.8, 125.8, 117...

Embodiment 2

[0053] Embodiment 2: Preparation of N-(4-methylphenyl)-1-phenyl-1-ethylamine

[0054]

[0055] Under nitrogen protection, add Ni(OTf) into a 10mL Schlenk reaction tube 2 (2.9mg, 0.008mmol), 1,2-bis(dicyclohexylphosphine)ethane (4.3mg, 0.010mmol) and tert-amyl alcohol (1.2mL), stirred for 10 minutes, then added 4-methylaniline (43mg , 0.4mmol), 1-phenylethanol (98mg, 0.8mmol) and Molecular sieves (100 mg). The reaction tube was sealed and heated in an oil bath at 120°C for 24 hours. After the reaction stopped, it was cooled, and the reaction solution was directly added to a silica gel column, and eluted with petroleum ether and ethyl acetate (volume ratio 20:1) to obtain pure N-(4-methylphenyl)-1-phenyl-1 -Ethylamine, 90% yield.

[0056] 1 H NMR (400MHz, CDCl 3 ): δ7.36(d, J=7.2Hz, 2H), 7.30(t, J=7.1Hz, 2H), 7.23-7.21(m, 1H), 6.89(d, J=7.6Hz, 2H), 6.43 (d, J=7.7Hz, 2H), 4.45(q, J=6.3Hz, 1H), 3.90(s, 1H), 2.18(s, 1H), 1.49(d, J=6.3Hz, 3H).

[0057] 13 C NMR (101MHz,...

Embodiment 3

[0058] Example 3: Preparation of N-(3,5-dimethylphenyl)-1-phenyl-1-ethylamine

[0059]

[0060] Under nitrogen protection, add Ni(OTf) into a 10mL Schlenk reaction tube 2 (2.9mg, 0.008mmol), 1,2-bis(dicyclohexylphosphine)ethane (4.3mg, 0.010mmol) and tert-amyl alcohol (1.2mL), stirred for 10 minutes, then added 3,5-dimethyl Aniline (49mg, 0.4mmol), 1-phenylethanol (98mg, 0.8mmol) and Molecular sieves (100 mg). The reaction tube was sealed and heated in an oil bath at 150°C for 24 hours. After the reaction stopped, cooled, the reaction solution was directly added to the silica gel column, and eluted with petroleum ether and ethyl acetate (volume ratio 20:1) to obtain pure N-(3,5-dimethylphenyl)-1-benzene Base-1-ethylamine, yield 72%.

[0061] 1 H NMR (400MHz, CDCl 3 ): δ7.36(d, J=7.2Hz, 2H), 7.31(t, J=7.2Hz, 2H), 7.25-7.20(m, 1H), 6.31(s, 1H), 6.16(s, 2H) ,4.47(q,J=6.3Hz,1H),3.90(s,1H),2.16(s,6H),1.49(d,J=6.4Hz,3H).

[0062] 13 C NMR (101MHz, CDCl 3 ): δ147.5, 145...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap