Device and method for efficiently preparing high-quality semi-solid aluminum alloy slurry

A semi-solid, aluminum alloy technology, applied to chemical instruments and methods, mixers with rotating stirring devices, mixers, etc., can solve the problems of low efficiency, unstable quality, and high manufacturing cost of semi-solid metal paste, and achieve High efficiency, stable slurry quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

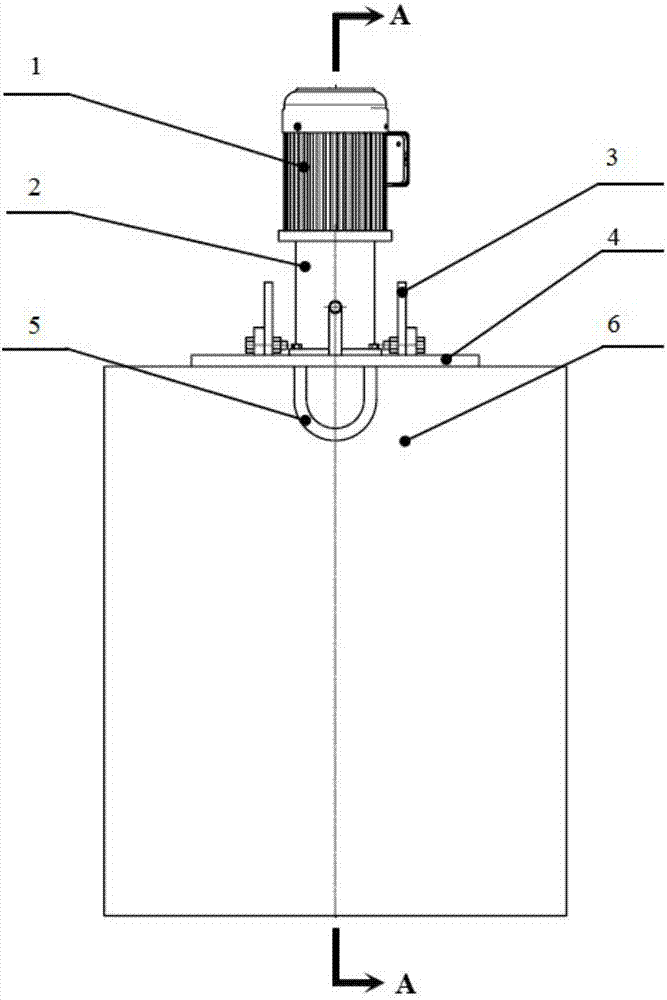

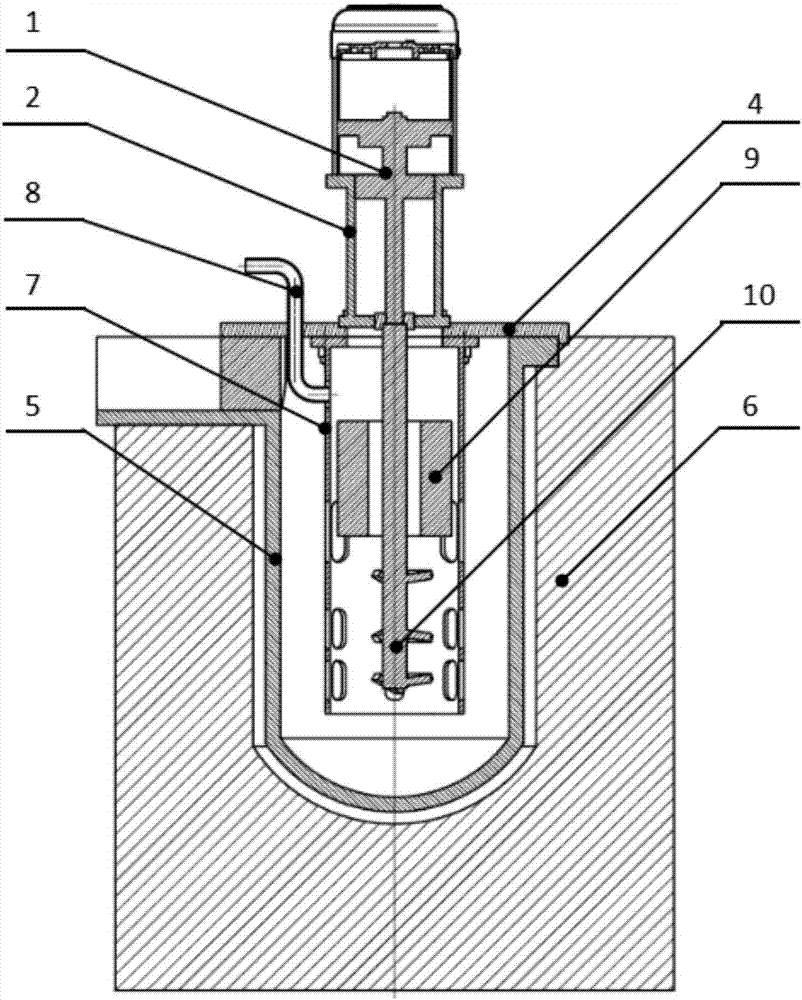

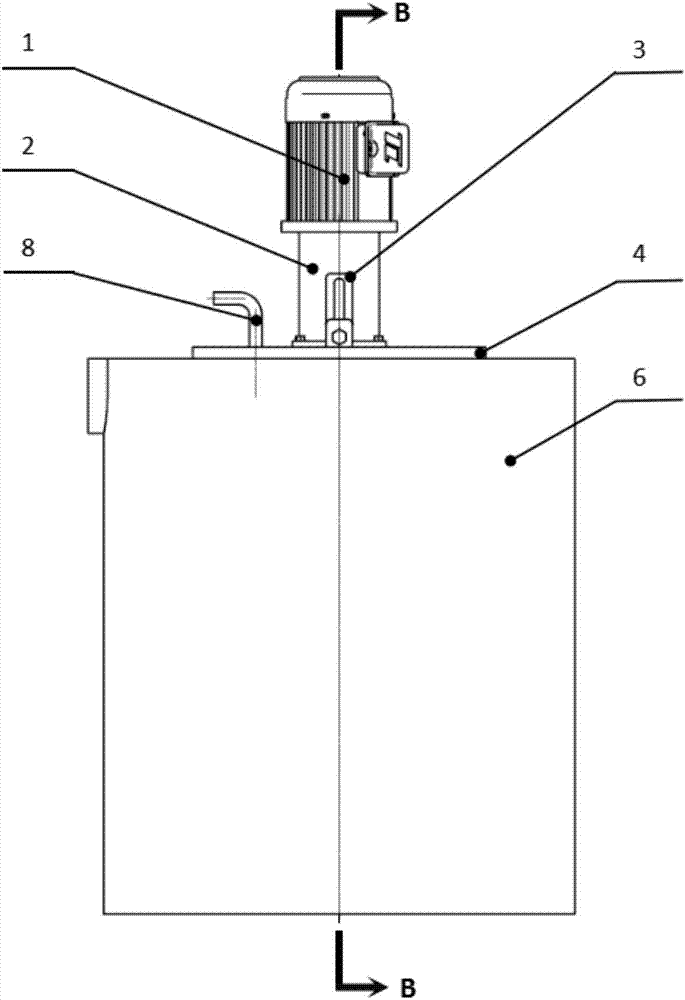

Image

Examples

Embodiment 1

[0052] This example is the preparation of semi-solid ZL101A alloy slurry and its SiC particle reinforced aluminum matrix composite material: the composition of ZL101A alloy material is Si: 6.96%, Mg: 0.35%, Ti: 0.15%, Fe: 0.1%, Ni: 0.01%, Zn: 0.01%, Cu: 0.01%, Mn: 0.01%, Sn: 0.01%, and the balance is Al. The liquidus and solidus temperatures of the ZL101A alloy are 615°C and 560°C, respectively.

[0053] The specific process is as follows:

[0054] 1) Melt 30Kg of ZL101A alloy in the crucible 5, when the temperature of the aluminum alloy melt in the crucible 5 reaches about 680°C, add a modifier, and then add argon for refining after the modification is completed (the amount added is the total amount of the alloy liquid 0.5% of the weight), argon gas is pressed into the bottom of the aluminum alloy liquid with a bell jar and gently swings to make the ZL101A alloy liquid boil completely. When there are no more bubbles in the bell jar, clean the slag with a scum spoon, and fin...

Embodiment 2

[0057] This embodiment is the preparation of semi-solid ZL114A alloy slurry: the composition of ZL114A alloy material is weight percent Si: 7.01%, Mg: 0.55%, Ti: 0.15%, Fe: 0.08%, Ni: 0.01%, Zn: 0.01% , Cu: 0.01%, Mn: 0.01%, Sn: 0.01%, and the rest is Al. The liquidus and solidus temperatures of the ZL101A alloy are 615°C and 560°C, respectively.

[0058] The specific process is as follows:

[0059] 1) Melt 50Kg of ZL114A alloy in the crucible 5, when the temperature of the aluminum alloy melt in the crucible 5 reaches about 690°C, add a modifier, and then add argon for refining after the modification is completed (the amount added is the total amount of the alloy liquid 0.5% of the weight), argon gas is pressed into the bottom of the aluminum alloy liquid with a bell jar and gently swings to make the ZL1141A light alloy liquid boil completely. When there are no more bubbles in the bell jar, clean the slag with a scum spoon, and finally reduce the temperature of the alloy li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com