Passive house wall structure

A wall structure, passive technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of large exchange of cold and hot air, poor air tightness, poor thermal insulation effect, etc. Strong tightness, reducing the loss of indoor cold and heat, and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

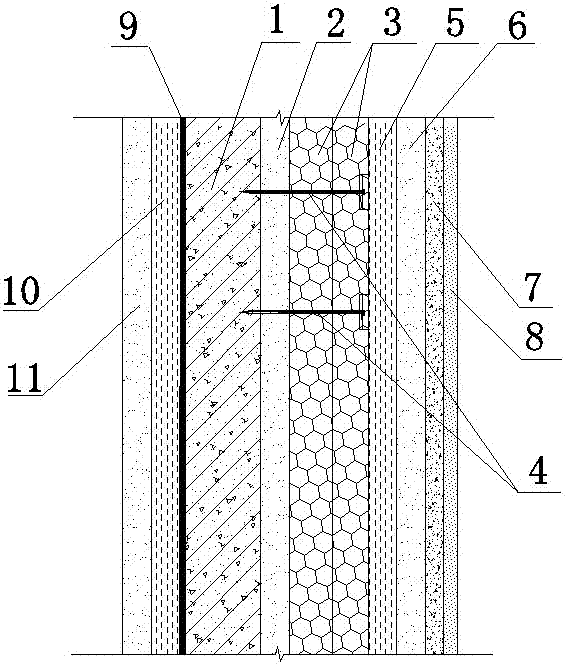

[0014] Such as figure 1 As shown, the present embodiment includes an outer wall body, a wall body 1 and an inner wall body. The wall body 1 is a building wall body after pouring reinforced concrete. The inner wall is composed of HIVP vacuum insulation board 9 , alkali-resistant glass fiber mesh cloth 10 and crack-resistant mortar layer 11 . Fix the HIVP vacuum insulation panel 9 on the inner wall of the wall. An alkali-resistant glass fiber mesh cloth 10 is fixed on the HIVP vacuum insulation panel 9 , and a crack-resistant mortar layer 11 is coated on the alkali-resistant glass fiber mesh cloth 10 . The outer wall is composed of crack-resistant leveling layer 2, graphite polystyrene board 3, alkali-resistant glass fiber mesh cloth 5, crack-resistant mortar layer 6, outer wall putty 7 and outer wall decoration layer 8. An anti-crack levelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com