Device and method for measuring leak tightness of interlayer containment of nuclear power station

A measuring device and containment technology, which is applied in the field of nuclear power plant interlayer containment airtightness measurement devices, can solve the problems of non-interleaved containment airtightness test schemes and systems, and achieve the effect of easy discovery and handling of abnormalities, and elimination of abnormalities or hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

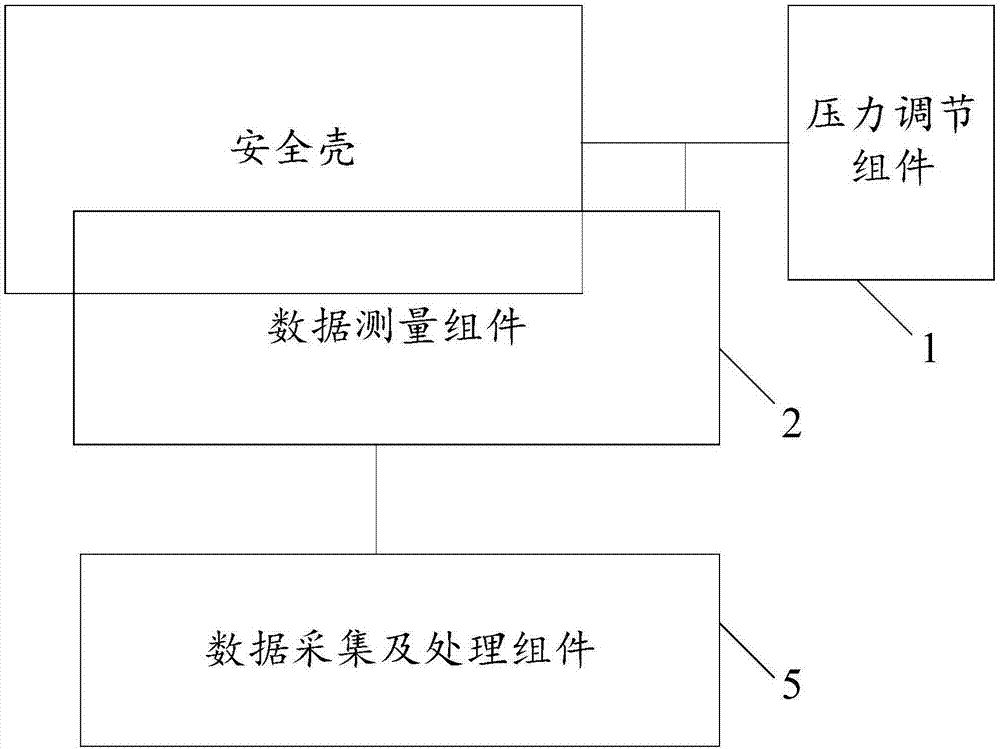

[0061] Please refer to figure 1 , Embodiment 1 of the present invention provides a nuclear power plant interlayer containment airtightness measurement device, including a pressure adjustment component 1, which communicates with the interlayer containment, and is used to change the internal pressure of the interlayer containment; a data measurement component 2, distributed in the interlayer containment Inside and outside, for measuring multiple measurement signals in the sandwich containment and in the atmosphere outside the sandwich containment at different internal pressures of the sandwich containment, and transmitting multiple measurement signals through different paths, the plurality of measurement signals include direct Transmitting measurement signals and measurement signals to be converted; data acquisition and processing components 5, connected to data measurement components 2 via the different paths, for calculating and obtaining interlayer according to the received di...

Embodiment 2

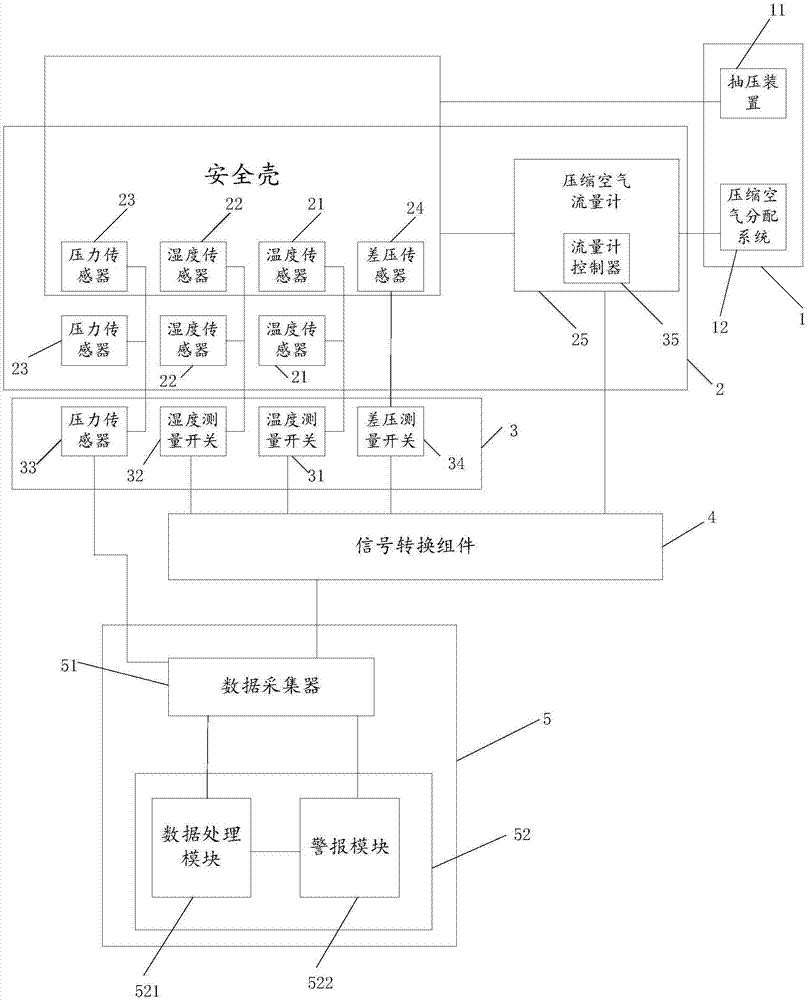

[0063] Such as figure 2 As shown, in the second embodiment provided by the present invention, different paths include a control component 3 and a signal conversion component 4: the control component 3 is used to control the operation of the data measurement component 2 and transfer the direct transmission measurement signal to the data acquisition And the processing component 5 and the control transfer the measurement signal to be converted to the signal conversion component 4; the signal conversion component 4 is connected to the control component 3, and transmits the measurement signal to be converted to the data acquisition and processing component after conversion. 5.

[0064] Specifically, the pressure regulating assembly 1 includes: a pumping device 11 for pumping the internal pressure of the interlayer containment to a preset negative pressure; a compressed air distribution system 12 for supplying A preset volume of compressed air is injected several times into the an...

Embodiment 3

[0094] Such as Figure 4 As shown, Embodiment 3 of the present invention provides a method for measuring the airtightness of a nuclear power plant interlayer containment, comprising the following steps:

[0095] S1. Change the internal pressure of the sandwich containment several times. Each time the internal pressure of the sandwich containment is changed, multiple measurement signals in the sandwich containment and in the atmosphere outside the sandwich containment are measured. The multiple measurement signals include directly transmitting measurement signals and The measurement signal needs to be converted;

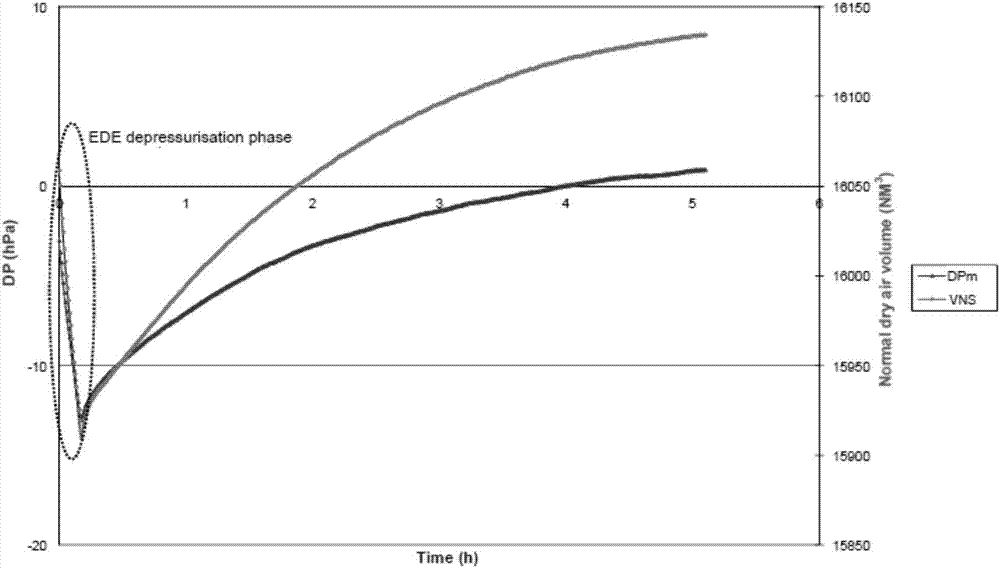

[0096] In this embodiment, the preset negative pressure of the interlayer containment is -7500Pa. After the pressure in the interlayer containment is pumped to -7500Pa by the pumping device 11, the parameters to be measured inside the interlayer containment and in the atmosphere outside the interlayer containment are measured. Carry out the calculation of the leakage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com