LED light string fully-automatic assembling apparatus and wire stripping mechanism thereof

A technology of LED light string and wire stripping mechanism, which is applied in equipment for dismantling/armouring cables, lighting and heating equipment, lighting devices, etc., which can solve the problems of high production and management costs, large equipment investment costs, and huge equipment investment costs, etc. problems, to achieve the effect of improved welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

[0026] Up, down, left, and right in this embodiment are only for the purpose of description, and are not used to limit the applicable scope of the present invention. Changes or adjustments of their relative relationships should be regarded as the applicable scope of the present invention.

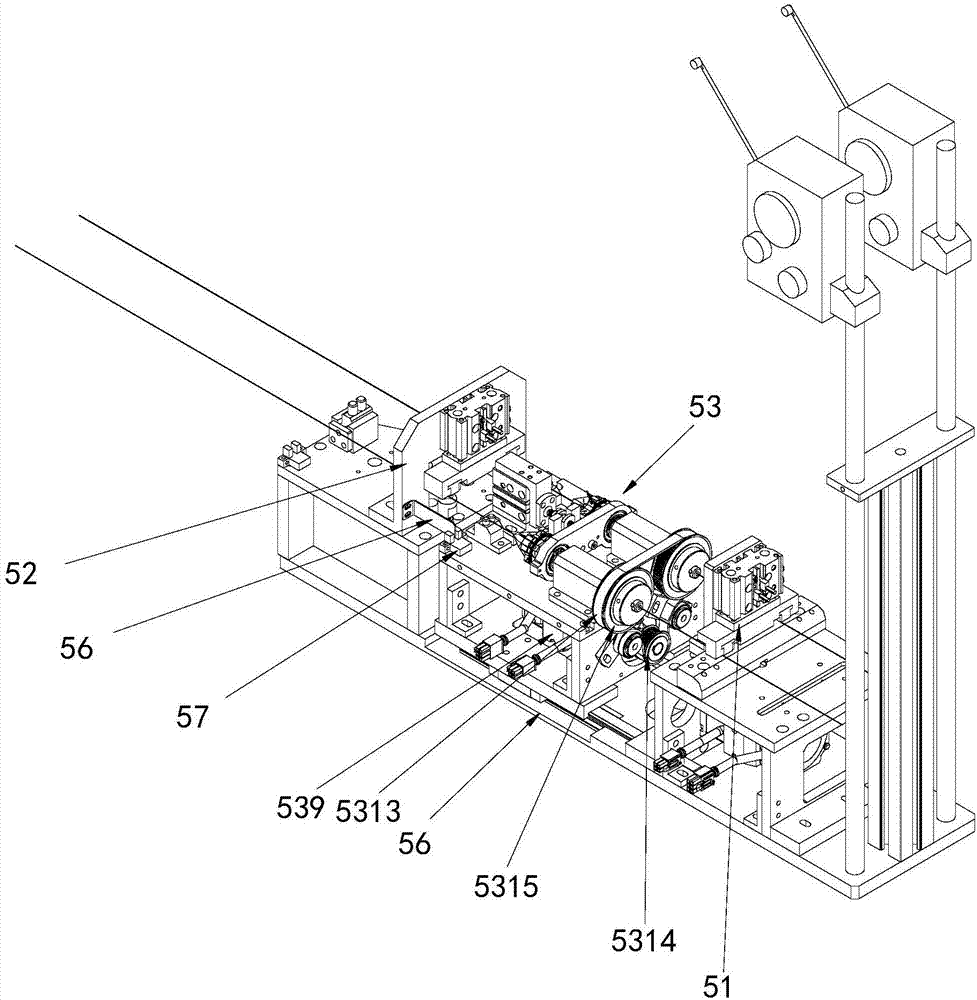

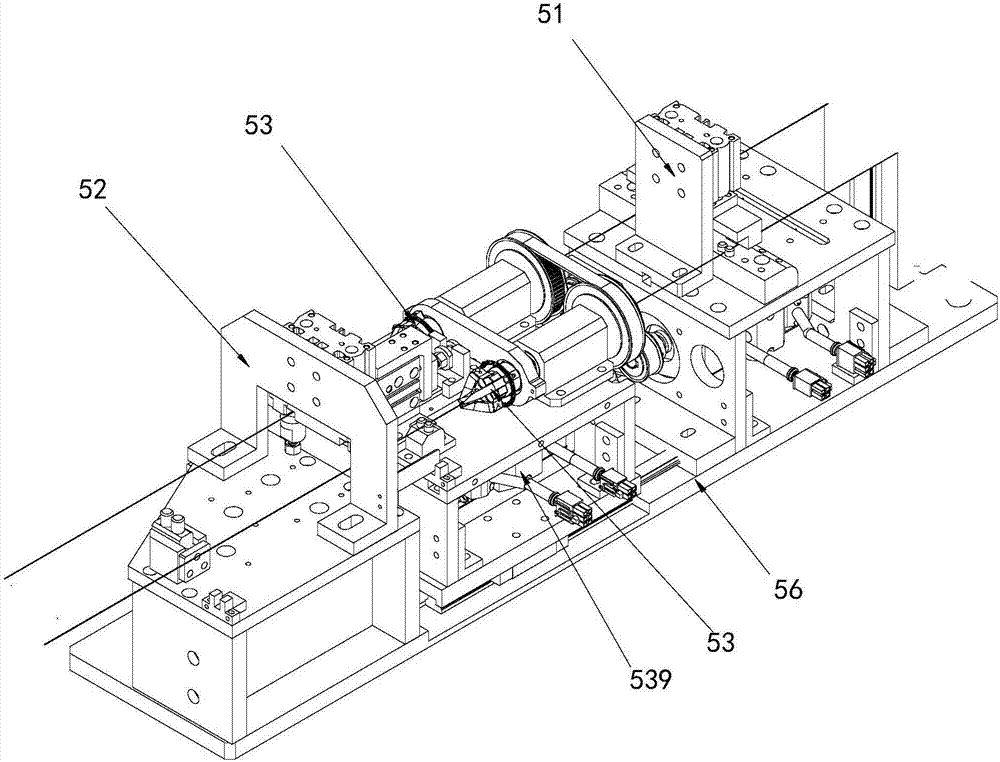

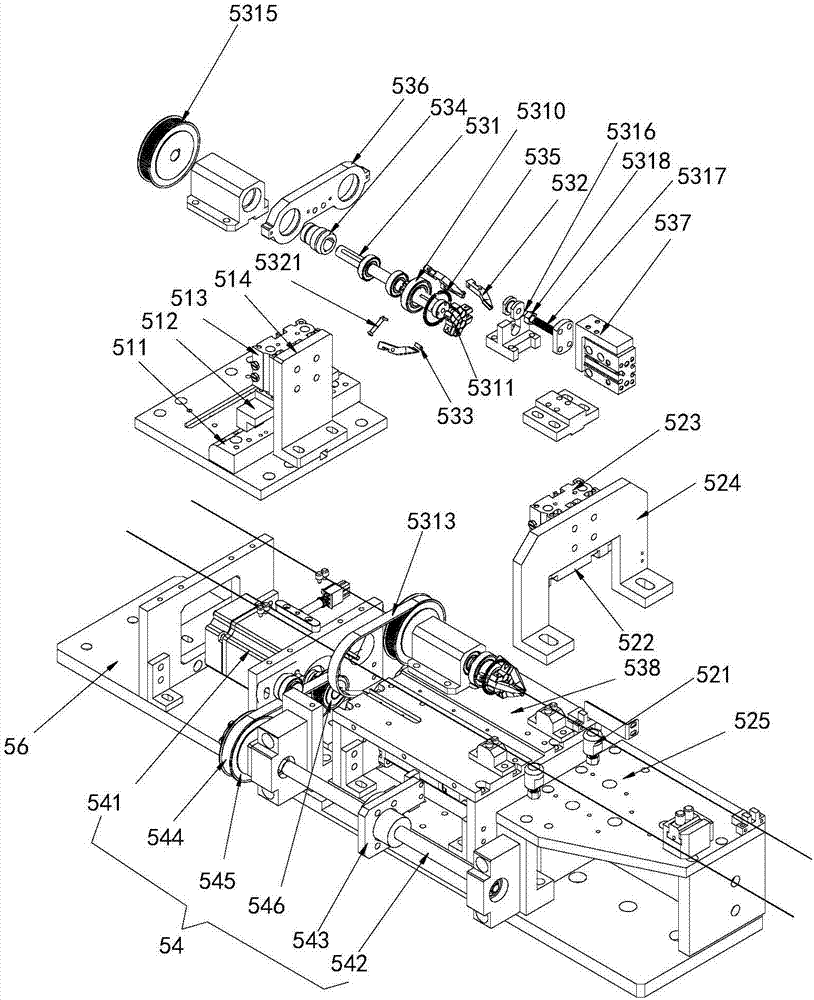

[0027] The wire stripping mechanism 50 of the fully automatic assembly equipment for LED light strings in this embodiment is set at the paint stripping station for peeling off the paint layer on the surface of the wire. Such as Figure 1-4 As shown, the wire stripping mechanism 50 in this embodiment includes a support plate 56, a rear wire pressing mechanism 51, a front wire pressing mechanism 52 and a rotating paint stripping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com