Pond ecology-based industrialized circulating water culture and purification system

A technology of circulating aquaculture and purification system, which is applied in the field of pond ecological industrialized recirculating aquaculture and purification system, which can solve the problems of waste of fresh water resources, high investment and high risk, high cost of tail water purification, etc., and achieve the effect of improving flow purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The technical solution of the present invention will be further described below in conjunction with specific embodiments.

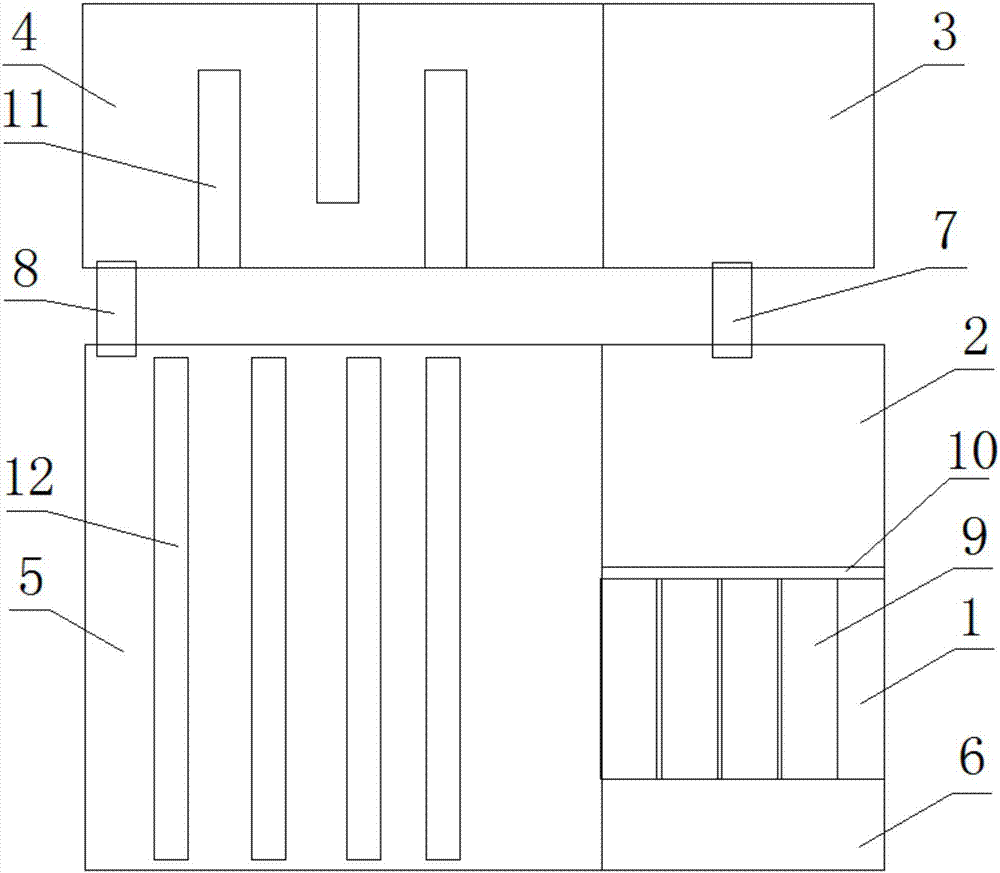

[0060] In the Pukou base of Jiangsu Freshwater Fisheries Research Institute, a set of pond ecological industrialization circulating aquaculture and purification system has been built. Such as figure 1As shown, the system divides the pond into a breeding area 1, a first-level biological purification area 2, a biological wetland purification area 3, an ecological purification corridor 4, an ecological oxidation pond 5, and a buffer zone 6; the breeding area 1 includes 4 vertical parallelepipeds Tank 9; the buffer zone 6 is located at the water inlet of the breeding area 1, and the first-level biological purification area 2 is located at the water outlet of the breeding area 1; the first-level biological purification area 2 and the biological wetland purification area 3 are separated by a pond ridge, passed A ditch 7 is connected; the left side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com