A kind of mesoporous carbon microsphere-supported composite material catalyst and its preparation method and application

A technology of composite materials and catalysts, which is applied in the direction of catalyst activation/preparation, preparation of amino compounds, chemical instruments and methods, etc. It can solve problems such as large difference in properties, influence of catalyst performance on catalytic reaction, etc., achieve strong transfer ability and inhibit dechlorination The effect of high performance, catalytic activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

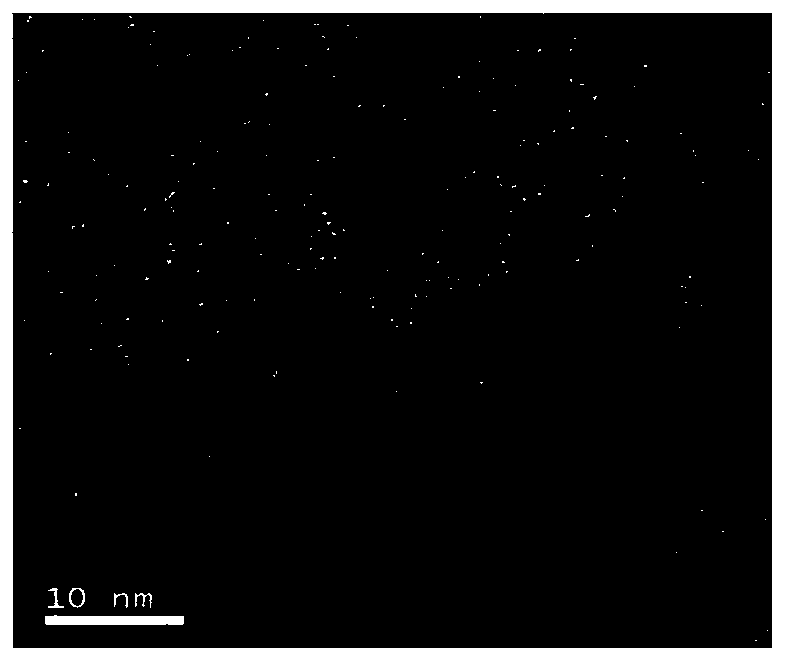

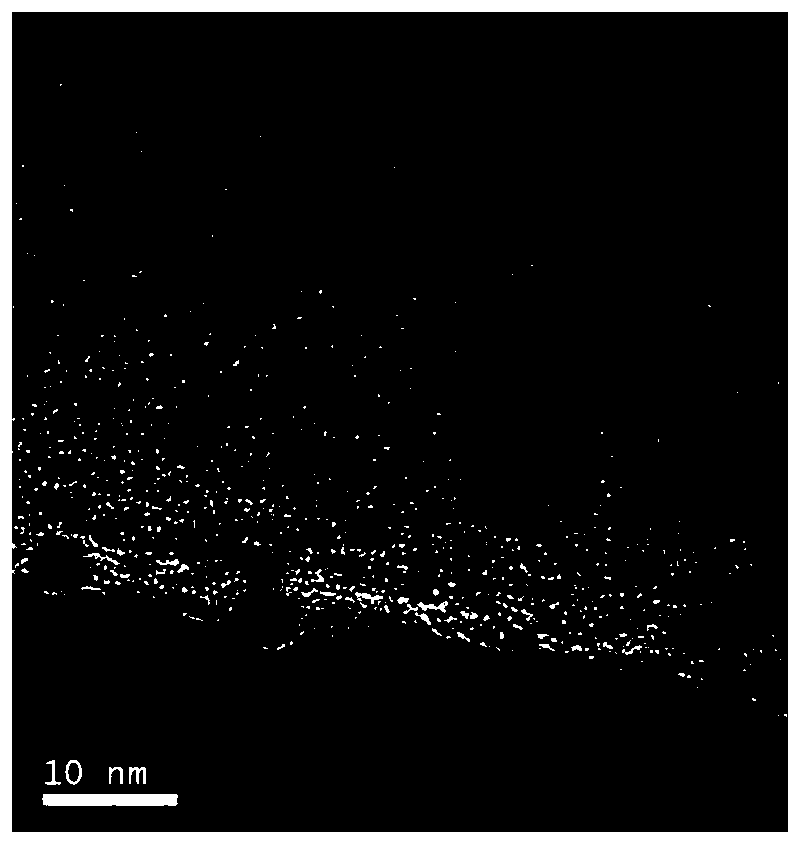

Image

Examples

Embodiment 1

[0049] Measure 0.8mL of ammonia water with a mass concentration of 25% to 28%, 1.5g of F127, 64mL of ethanol, and 160mL of deionized water, and stir the three thoroughly, then add 1.6g of resorcinol, stir until completely dissolved, and slowly drop Add 2.24 mL of formaldehyde solution with a mass concentration of 37-40%, stir at 20°C for 12 hours, transfer to a hydrothermal reaction kettle at 80°C for 12 hours, and then centrifuge and wash to obtain a reddish-brown polymer solid powder.

[0050] Weigh 3g of alanine and dissolve it in 30mL of deionized water, add 1.12mL of ethylenediamine, stir evenly, transfer the mixture to a reaction kettle at 100°C for 5 hours, then transfer the reaction solution to a molecular weight cut-off of 1000 The dialysis bag was dialyzed for 12 hours; then the dialysate was freeze-dried at a relative vacuum of -0.099 to -0.05MPa and a temperature of -10°C for 10 hours to obtain a carbon quantum dot solid powder.

[0051] Get 20mL of palladium metal...

Embodiment 2

[0054] Measure 0.8mL of ammonia water with a mass concentration of 25% to 28%, 0.5gF127, 96mL of ethanol, and 120mL of deionized water and stir the three thoroughly, then add 1.6g of resorcinol, stir until completely dissolved, and slowly drop Add 3 mL of formaldehyde solution with a mass concentration of 37-40%, stir at 25°C for 20 hours, transfer to a hydrothermal reaction kettle at 100°C for 15 hours, and then centrifuge and wash to obtain a reddish-brown polymer solid powder.

[0055] Weigh 3.4g of alanine and dissolve it in 31mL of deionized water, add 1.15mL of ethylenediamine, stir evenly, transfer the mixture to a reaction kettle at 100°C for 5 hours, then transfer the reaction solution to The 9000 dialysis bag was dialyzed for 12 hours; then the dialysate was freeze-dried at a relative vacuum of -0.099 to -0.05MPa and a temperature of -10°C for 10 hours to obtain a quantum dot solid powder.

[0056] Take 60mL of the palladium metal concentration of 0.001g / mL ammonium ...

Embodiment 3

[0059] Measure 0.8mL of ammonia water with a mass concentration of 25% to 28%, 2.0g of F127, 64mL of ethanol, and 180mL of deionized water, and stir the three thoroughly, then add 1.6g of resorcinol, stir until completely dissolved, and slowly drop Add 4 mL of formaldehyde solution with a mass concentration of 37-40%, stir at 10°C for 30 hours, transfer to a hydrothermal reaction kettle at 35°C for 18 hours, and then centrifuge and wash to obtain a reddish-brown polymer solid powder.

[0060] Weigh 3g of alanine and dissolve it in 30mL of deionized water, add 2mL of ethylenediamine, stir evenly, transfer the mixed solution to a reaction kettle at 120°C for 5 hours, then transfer the reaction solution to a reactor with a molecular weight cut-off of 1000 The dialysis bag was dialyzed for 24 hours; then the dialysate was dried at a relative vacuum of -0.099 to -0.05 MPa at a temperature of 50° C. and freeze-dried for 5 hours to obtain solid powder of quantum dots.

[0061] Get 38...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com