Self-optimizing alloy catalyst as well as preparation method and application thereof

An alloy catalyst and a self-optimizing technology, applied in the field of self-optimizing alloy catalyst and its preparation, can solve the problems of reduced catalytic activity, poor catalyst stability, and reduced catalytic performance, and achieve stable catalytic performance, reduced catalytic cost, and high current density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

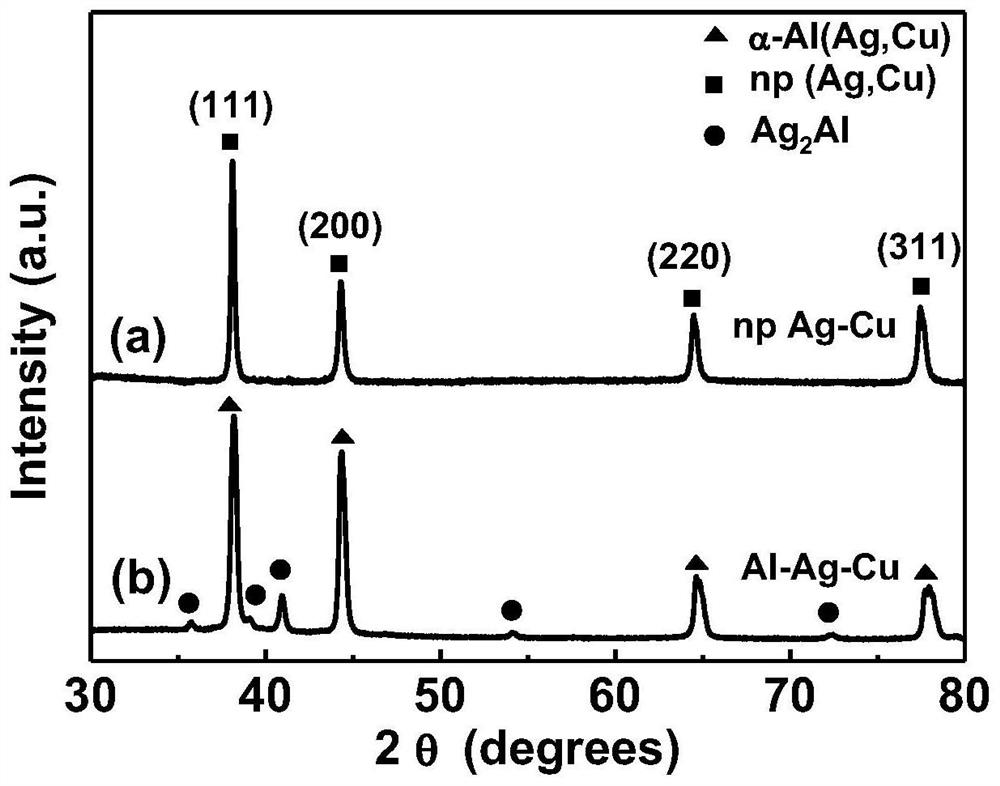

[0034] (1) Use a balance to weigh 5.5g high-purity Al (purity is 99.99%), 0.5g high-purity Ag (purity is 99.999%), 4g high-purity Cu (purity is 99.999%), add 20ml of absolute ethanol and 20ml acetone, ultrasonically cleaned for 3 minutes, then cleaned with alcohol, and dried with nitrogen; then put the above-mentioned metal raw materials into a vacuum arc melting furnace, and use a molecular pump to evacuate to 8×10 -2 Pa, and then filled with high-purity argon gas to 0.1Pa, start the vacuum arc melting furnace for melting, when melting, the front and back sides are melted once for one round, a total of 5 rounds of melting, the melting current is 150A, and Ag is obtained 20 Cu 0.5 Al 79.5 alloy;

[0035](2) Take out the above alloy, wash it three times with absolute ethanol and acetone with a volume ratio of 1:1, dry it with nitrogen, and then use a cutting machine to cut it into strips with a length of 10 mm and a width of 5 mm. Put the above-mentioned quartz tube into the...

Embodiment 2

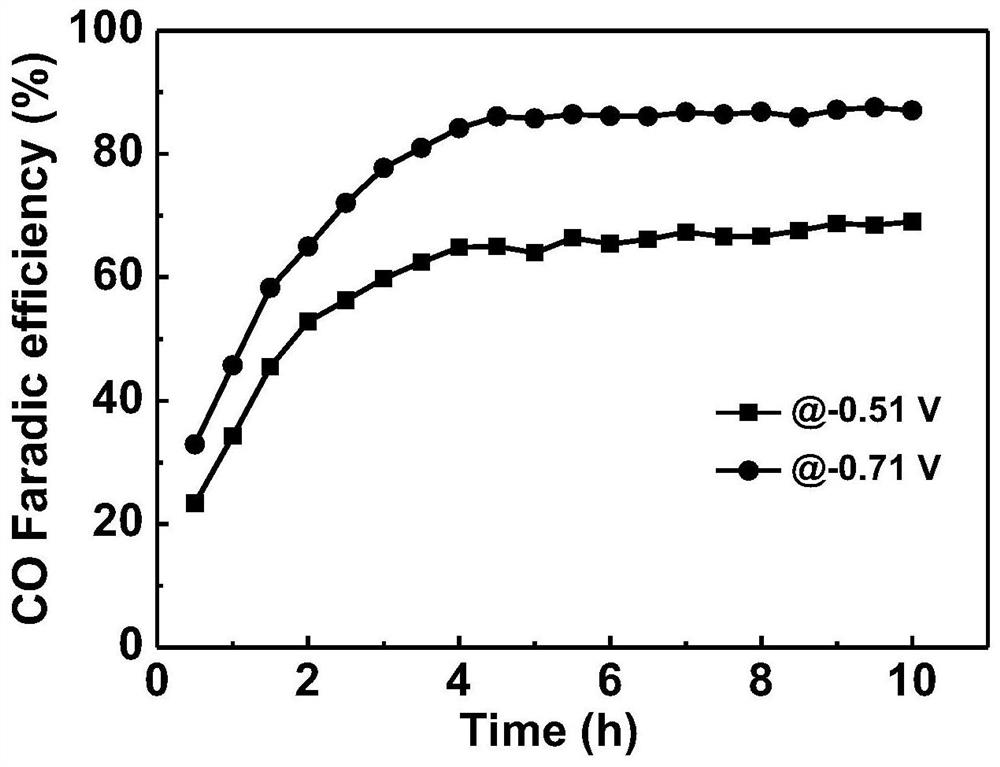

[0039] The main difference between this embodiment and Embodiment 1 is that the optimized voltage in step (4) is different, and the optimized voltage is set to -0.71V in this application, as described below.

[0040] (1) Use a balance to weigh 5.5g high-purity Al (purity is 99.99%), 0.5g high-purity Ag (purity is 99.999%), 4g high-purity Cu (purity is 99.999%), add 20ml of absolute ethanol and 20ml acetone, ultrasonically cleaned for 3 minutes, then cleaned with alcohol, and dried with nitrogen; then put the above-mentioned metal raw materials into a vacuum arc melting furnace, and use a molecular pump to evacuate to 8×10 -2 Pa, and then filled with high-purity argon gas to 0.1Pa, start the vacuum arc melting furnace for smelting, when smelting, the front and back sides are smelted once for one round, and a total of 8 rounds of smelting, the smelting current is 180A, to obtain Ag 20 Cu 0.5 Al 79.5 alloy;

[0041] (2) Take out the above alloy, wash it with 1:1 absolute ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com