Turning tool and machining method of thin-walled cylindrical workpiece

A thin-walled cylinder and tooling technology, which is applied in the field of mechanical processing, can solve problems such as turning deformation of thin-walled cylindrical workpieces, and achieve the effects of solving deformation problems, convenient operation, and ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

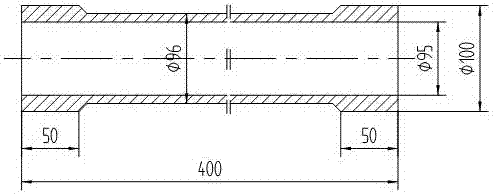

[0019] figure 1 It is a schematic diagram of the product structure of this embodiment. It can be seen from the figure that the thin-walled cylindrical workpiece is 400mm long, the 50mm long wall thickness at both ends is 2.5mm, and the nearly 300mm long wall thickness in the middle is only 1mm. Workpieces with a structure like this, if mass-produced, are usually produced by the thickening process at both ends of the steel pipe with a wall thickness of 1mm. However, for processing plants without pier roughing equipment, the cost of single-room production pier roughing is very high, and conventional turning methods cannot be realized.

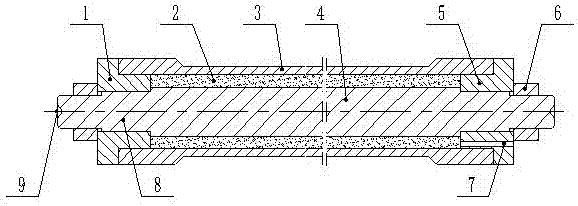

[0020] In order to realize the single-piece processing and production of thin-walled cylindrical workpieces, the present invention provides a simple turning tool, such as figure 2 As shown, it is a schematic diagram of the structure of the thin-walled cylindrical workpiece product and its tooling in this embodiment. Pass the stepped mandrel 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com