Narrow space bolt positioning and installing robot and control method

A technology of bolt positioning and robotics, which is applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., and can solve problems such as inability to assemble, difficulty in manually operating tools, and limited visible range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

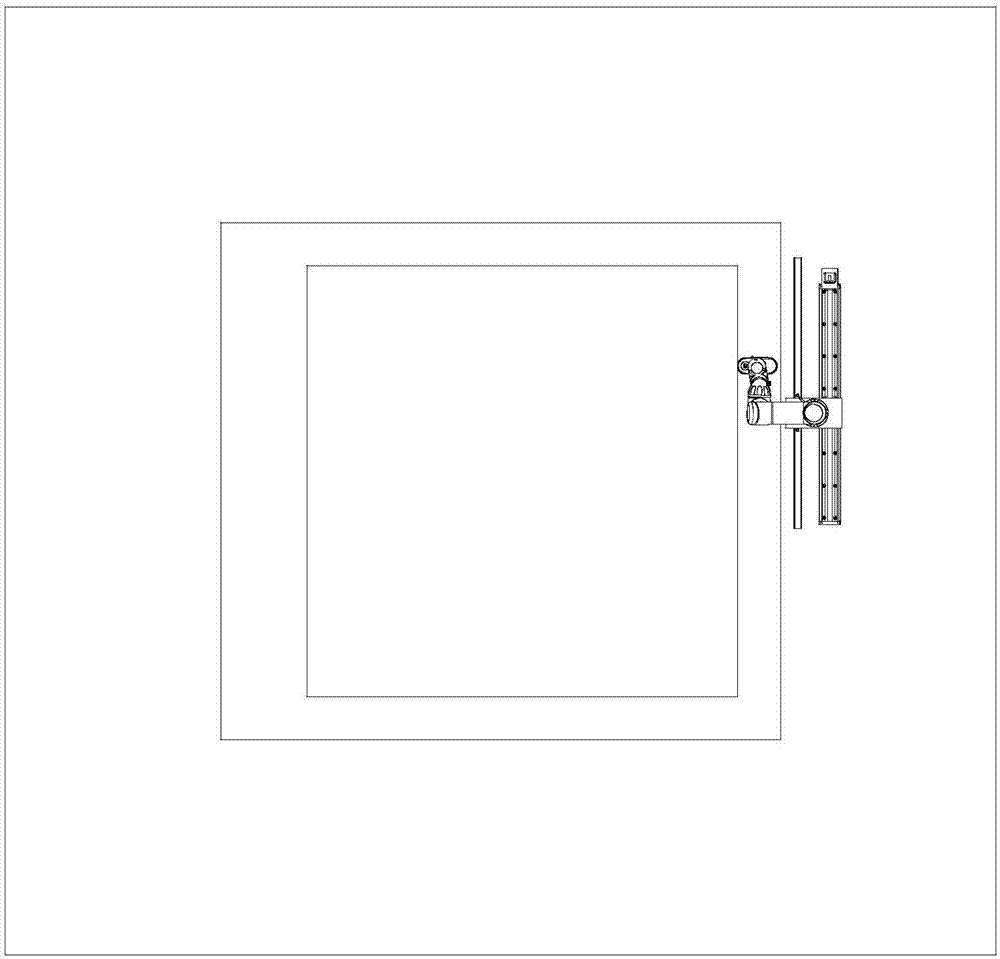

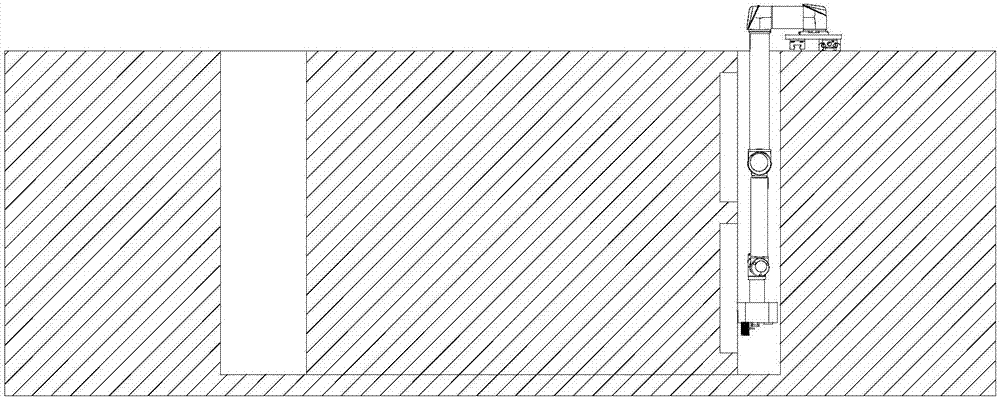

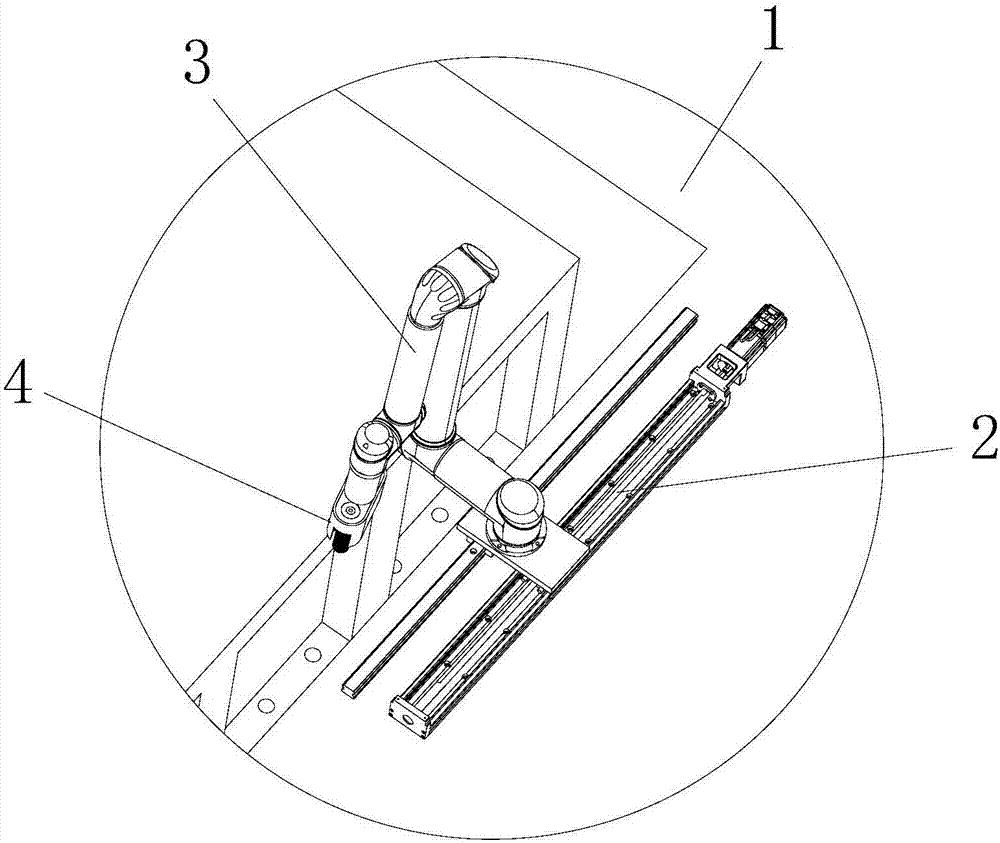

[0084] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the present invention discloses a bolt positioning installation robot in a narrow space. The robot is mainly used for assembling threaded holes in a narrow space. The structure mainly includes an installation platform 1 for fixing and installing the robot, and a fixed plate, fixture 4 for tightening bolts, industrial robot 3 for driving fixture 4 to a specified position, motion module 2 for driving industrial robot 3 translation, and processing image data and driving each execution The widget's controller. The installation platform 1 is fixed, the fixed plate is installed on the installation platform 1, the motion module 2 is installed on the fixed plate, the tooling fixture 4 is installed at the end of the industrial robot 3, and the industrial robot 3 is installed on the moving On the module 2, the controller is electrically connected to the motion module 2, the industrial ro...

Embodiment 2

[0138] The invention provides a bolt positioning and installation robot in a narrow space, which specifically includes a mechanical unit, a control unit, a drive unit, a vision unit, and a display operation unit.

[0139] Preferably, the mechanical unit includes a 6-joint general-purpose industrial robot 3, a special fixture 4, and a motion module 2.

[0140] Preferably, the 6-joint general-purpose industrial robot 3 adopts a motor-built-in six-joint series structure, wherein each arm has a fully expanded length of 1500mm, a maximum arm diameter of 100mm, a minimum arm diameter of 60mm, and a maximum load of 300Kg, which can be used in a narrow space of 200mm. work inside.

[0141] Preferably, the 6-joint general-purpose industrial robot 3 is made of materials such as aluminum alloy, steel parts, and ABS plastic, and its weight reaches about 35kg.

[0142] Preferably, the 6-joint general-purpose industrial robot 3 is equipped with a pressure sensor, which can automatically st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com