Precision machining method for small-aperture rotating shaft symmetric optical cambered elements

A technology of precision machining and rotating shaft, applied in the direction of stone processing equipment, stone processing tools, metal processing equipment, etc., can solve the problems of limited processing materials, large accumulated errors, low processing accuracy and processing efficiency, etc., to achieve high processing efficiency, The effect of reducing accumulated errors, improving machining accuracy and machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

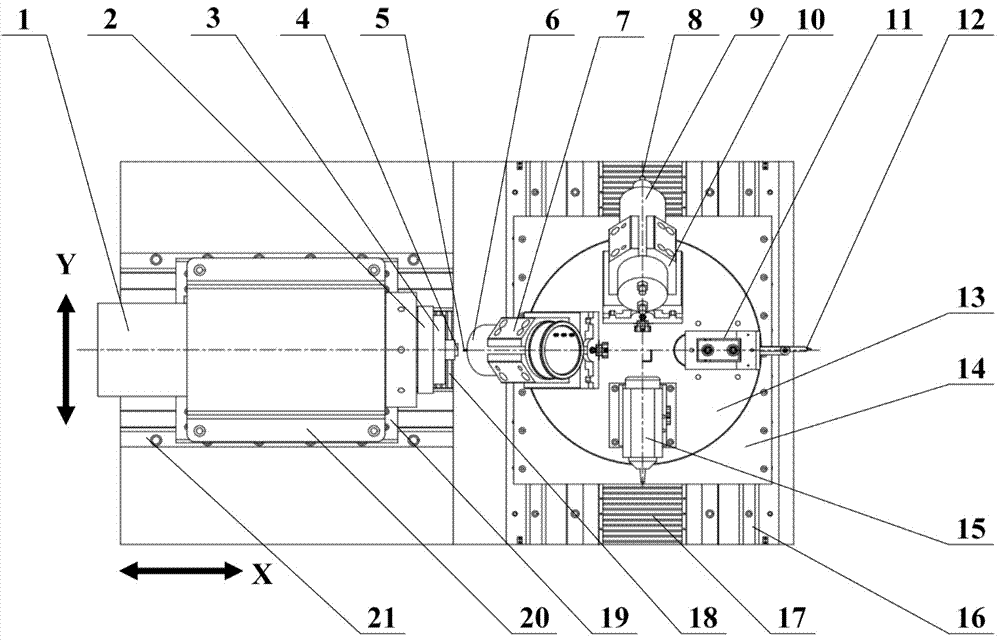

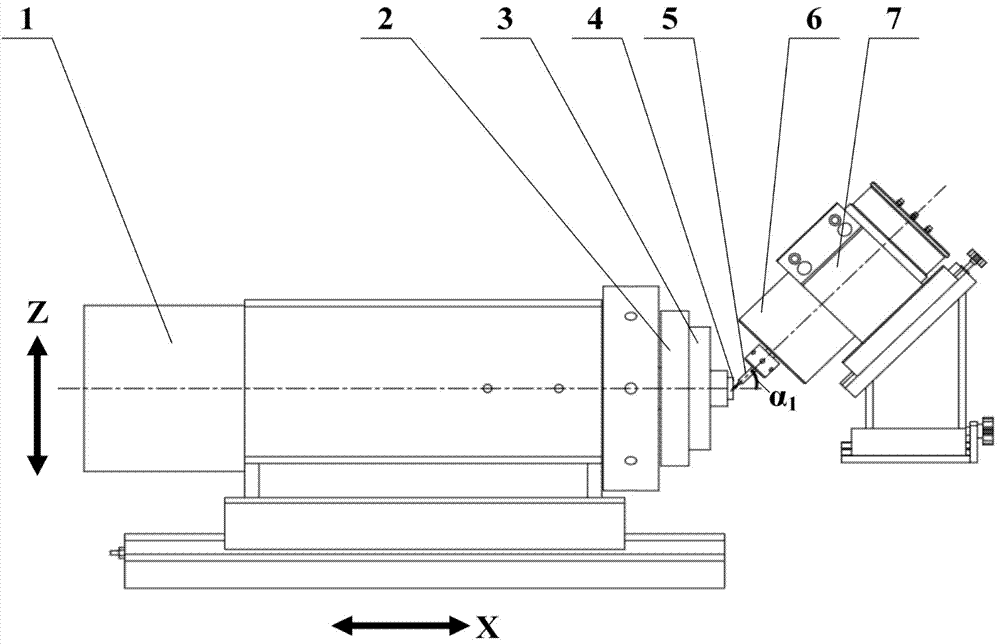

[0038] See attached figure 1 , 2 , 3, 5, the material of the workpiece to be processed is FB05 cemented carbide produced by Daijie Industrial Co., Ltd., the workpiece blank is a cylinder (size is Φ20mm×10mm), the surface of the workpiece to be processed is located at the end surface of the cylinder, and its shape is Axisymmetric aspherical concave surface, the aspheric diameter is 10mm. The processing of the above-mentioned workpieces is completed on a precision machining machine tool for small-diameter rotating axisymmetric optical curved surface elements, and the following procedures are followed:

[0039] Process 1: Fix the workpiece holder 3 with the workpiece 4 to be processed on the right end of the workpiece spindle 1 through the vacuum chuck 2; rotate the rotary table 13 to make the milling spindle 6 of the oblique-axis micro-milling device 7 The axis is inclined to the axis of workpiece spindle 1 by ∠α 1 The angle intersects, ∠α 1 The value of the angle is 45°; t...

Embodiment 2

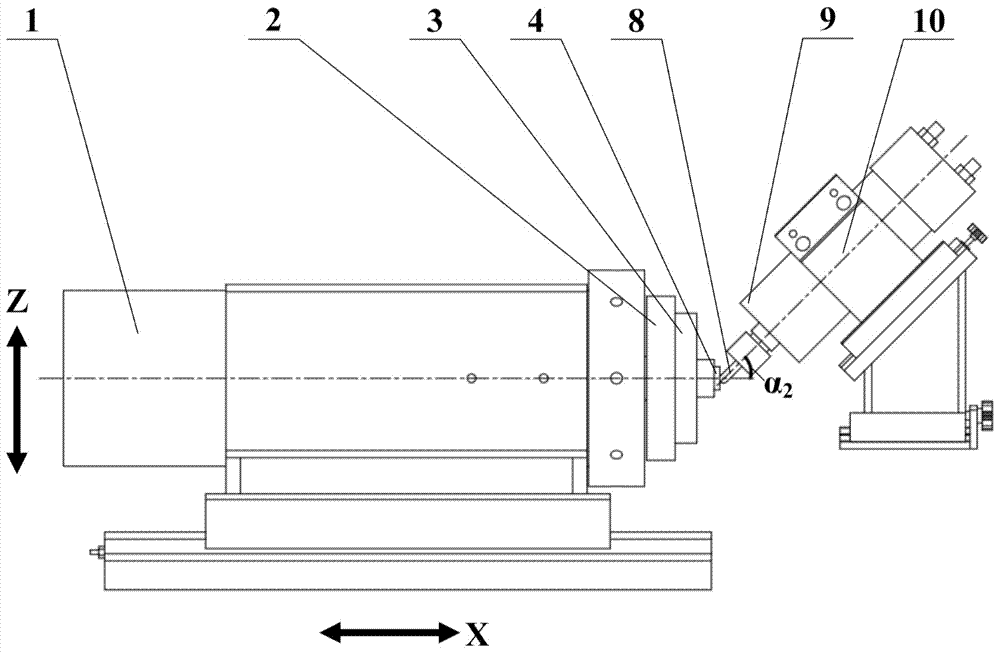

[0049] See attached figure 1 , 3 , 4, 5, the material of the workpiece to be processed is brass for commercially available H62 molds, the workpiece blank is a cylinder (size Φ20mm×10mm), the surface of the workpiece to be processed is located at the end surface of the cylinder, and its shape is an axisymmetric concave spherical surface , the diameter of the concave spherical surface is 10mm. The processing of the above-mentioned workpieces is completed on a precision machining machine tool for small-diameter rotating axisymmetric optical curved surface elements, and the following procedures are followed:

[0050] Process 1: Fix the workpiece holder 3 with the workpiece 4 to be processed on the right end of the workpiece spindle 1 through the vacuum chuck 2; rotate the rotary table 13 so that the center line of the single-point diamond turning tool 12 is aligned with the workpiece The axes of the main shaft 1 are coincident; the tool setting of the workpiece 4 and the single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com