A hydraulically driven transfer device

A transfer device, hydraulic technology, applied in the directions of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of poor maintenance efficiency, easy jamming, high work intensity, etc., achieve easy automatic control, achieve mechanical positioning, high The effect of power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

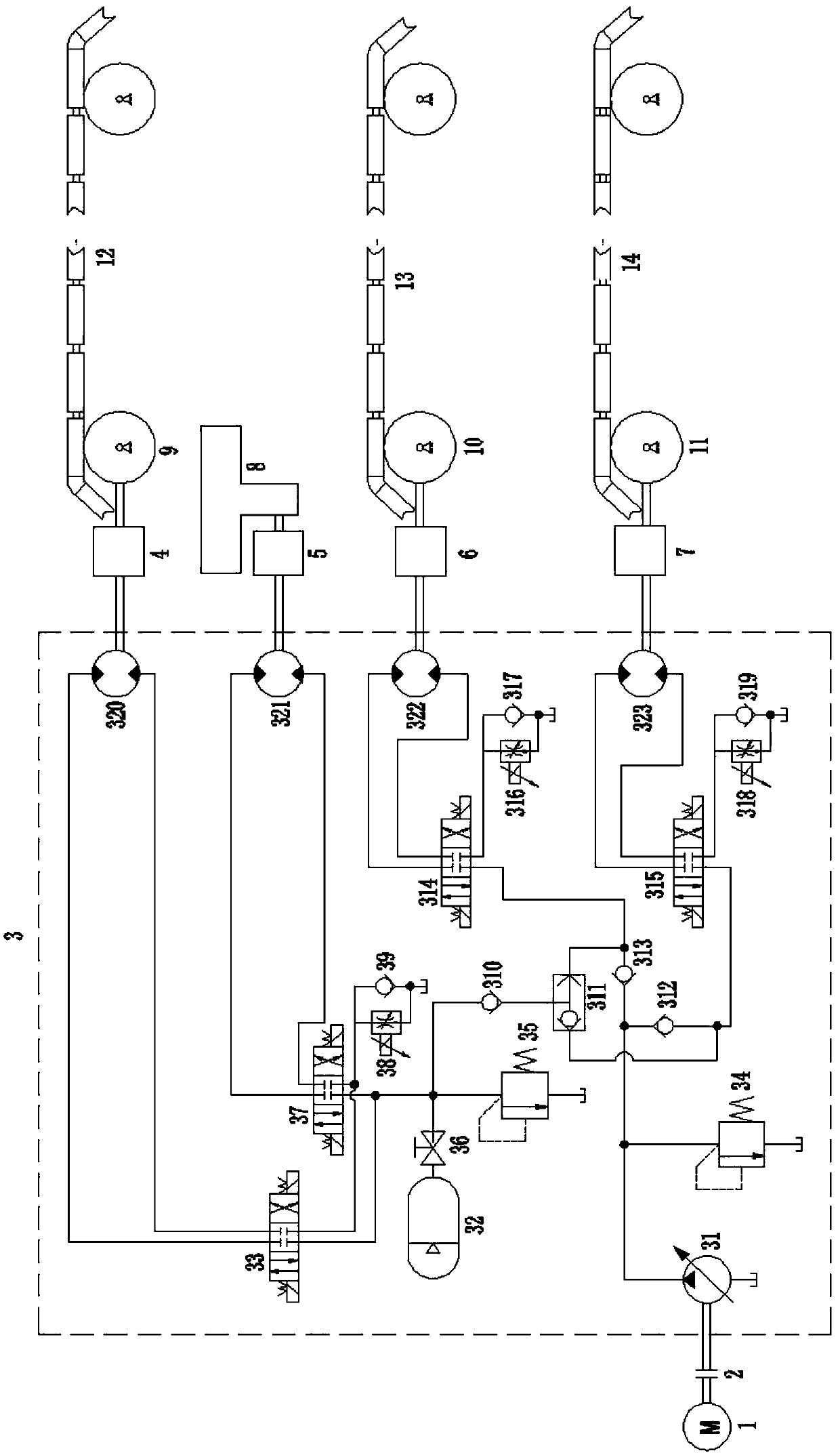

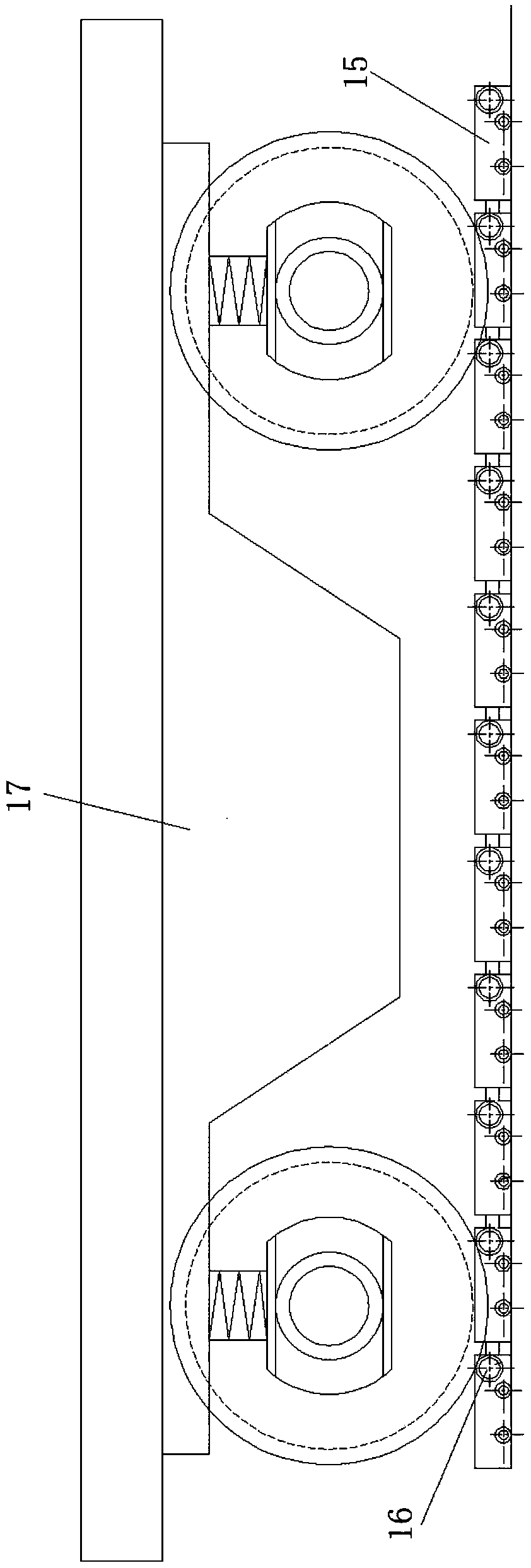

[0019] The specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings. The interpretation of each label in the figure is: 1-motor, 2-electromagnetic clutch, 3-hydraulic drive system, 4-first speed reducer, 5-second speed reducer , 6-third reducer, 7-fourth reducer, 8-turntable, 9-first sprocket, 10-second sprocket, 11-third sprocket, 12-first track, 13-second Rail, 14-third rail, 31-pressure-limiting variable pump, 32-accumulator, 33-first electromagnetic reversing valve, 34-first overflow valve, 35-second overflow valve, 36-manual Stop valve, 37-second electromagnetic reversing valve, 38-first electromagnetic speed regulating valve, 39-first one-way valve, 310-second one-way valve, 311-shuttle valve, 312-third one-way valve, 313-the fourth one-way valve, 314-the third electromagnetic reversing valve, 315-the fourth electromagnetic reversing valve, 316-the second electromagnetic speed control valve, 317-the fifth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com