Evaporator

A technology for evaporators and evaporator tubes, applied in chemical instruments and methods, heating water/sewage treatment, water/sewage treatment, etc., can solve the problems of heat transfer performance decline, heat transfer efficiency drop of evaporator heat exchange tubes, easy to block, etc. problem, to achieve the effect of accelerating evaporation time, prolonging operation cycle and increasing heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

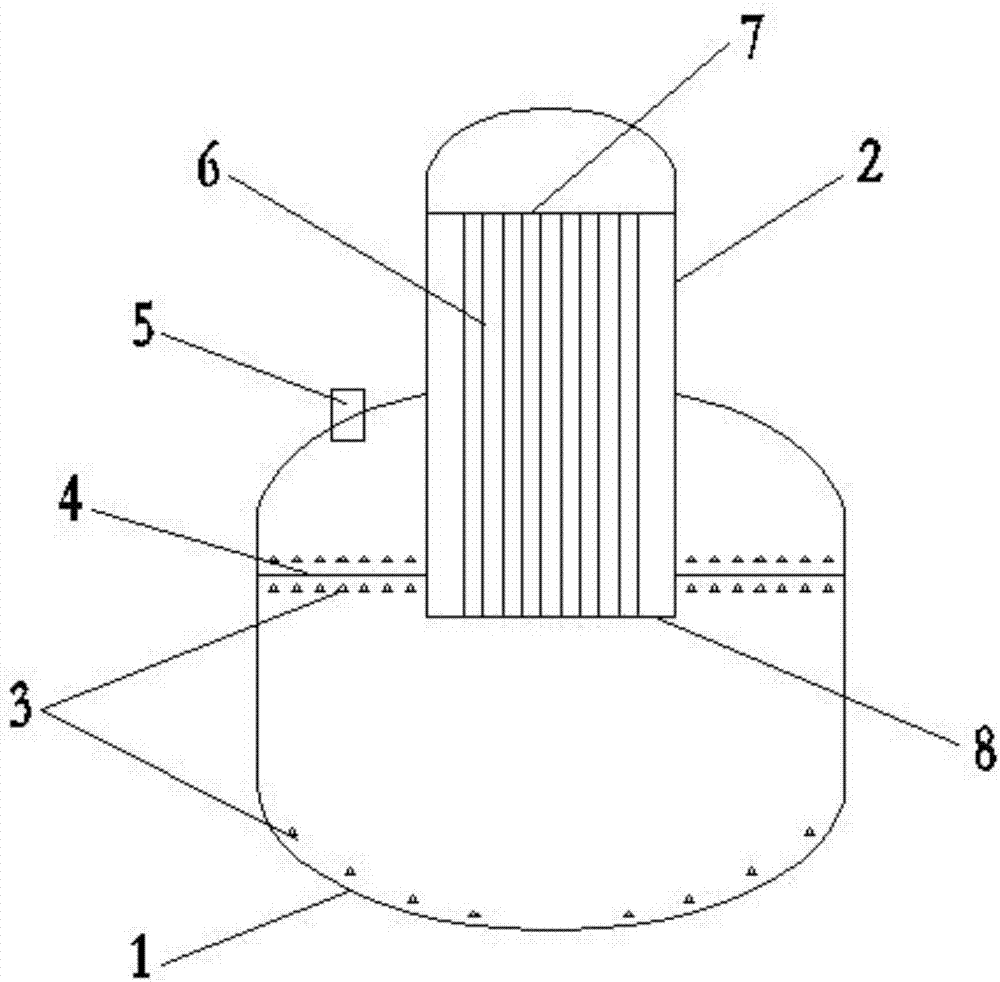

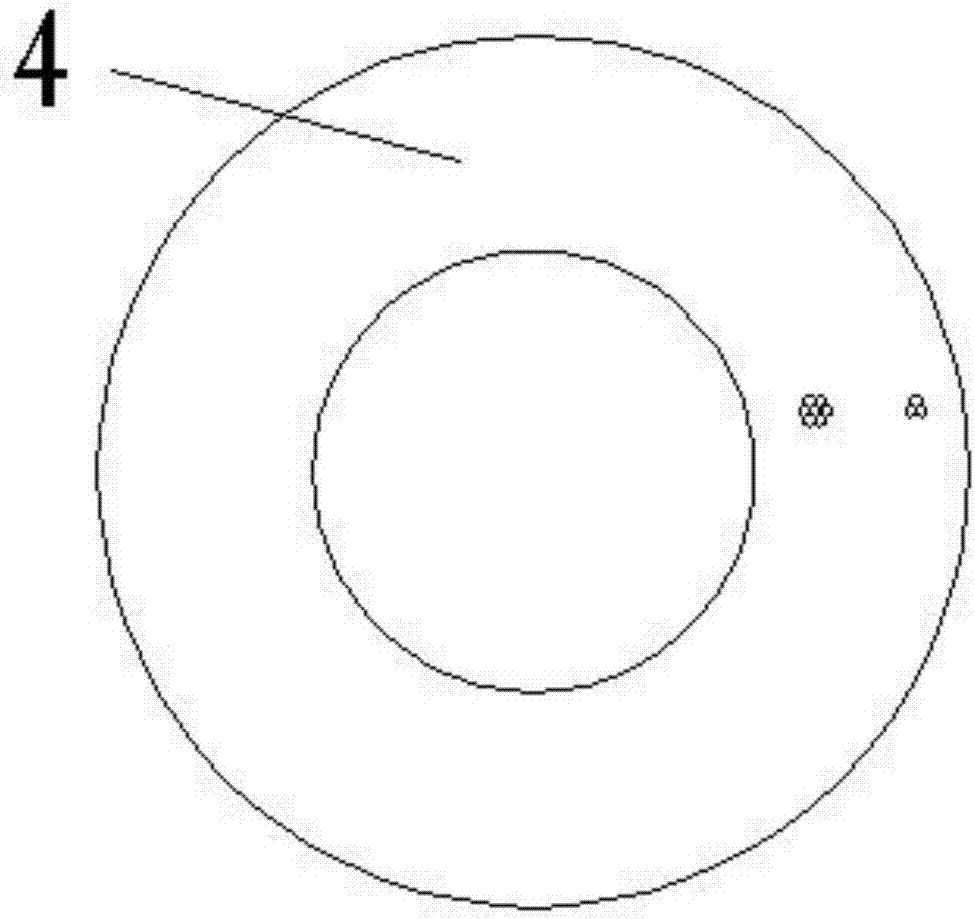

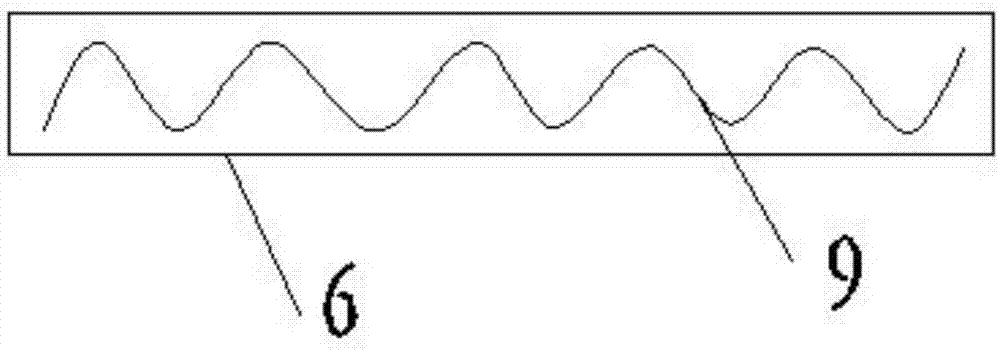

[0019] Such as figure 1 As shown, the present invention discloses an evaporator, which includes a box body 1 and an evaporation tube 2 inserted vertically from the upper part of the box body 1; , the inside of the box 1 is provided with a filter plate 4, the filter plate 4 divides the inside of the box 1 into upper and lower parts, the bottom end of the evaporation tube 2 passes through the filter plate 4, and the connection with the filter plate 4 is sealed connection; the upper end of the box body 1 is provided with a hole-shaped head structure 5, such a head structure 5 forms a closed small space with the box body 1 and the filter plate 4, and the evaporated material is fed from the head structure 5; The inside of the evaporation tube 2 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com