Anisotropic polyimide aerogel material and preparation method thereof

A technology of polyimide and airgel, applied in the field of polyimide airgel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

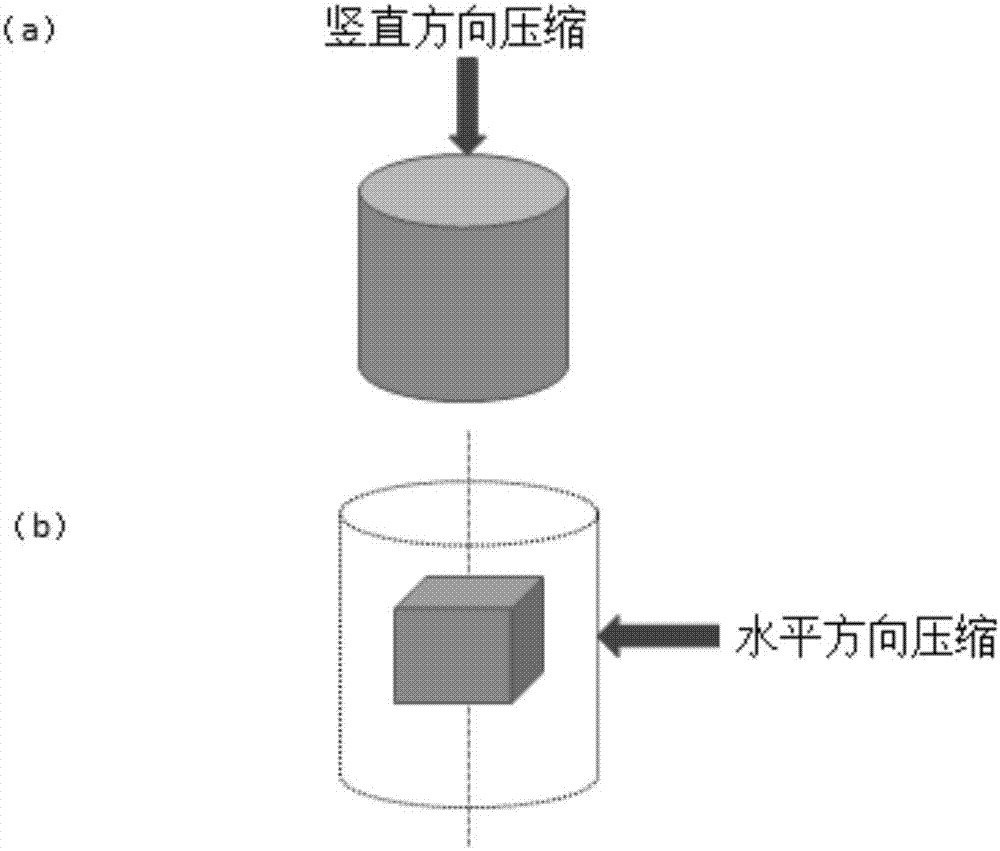

[0053] The preparation of the polyimide airgel of embodiment 1 anisotropy

[0054] 1. Preparation of polyamic acid ammonium salt (PAS) aqueous solution

[0055] PAS aqueous solution with a mass ratio of polyamic acid to water of 3:97: Take 10g of polyamic acid, add 323.3g of deionized water, add dropwise 4.76g of triethylamine, and stir evenly with magnetic force.

[0056] PAS aqueous solution with a mass ratio of polyamic acid to water of 5:95: Take 10g of polyamic acid, add 190g of deionized water, add dropwise 4.76g of triethylamine, and stir evenly with magnetic force.

[0057] PAS aqueous solution with a mass ratio of polyamic acid to water of 8:92: take 10g of polyamic acid, add 115g of deionized water, add dropwise 4.76g of triethylamine, and stir evenly with magnetic force.

[0058] PAS aqueous solution with a mass ratio of polyamic acid to water of 10:90: Take 10g of polyamic acid, add 90g of deionized water, add dropwise 4.76g of triethylamine, and stir evenly with ...

Embodiment 2

[0061] Example 2 Preparation of anisotropic polyimide / multi-walled carbon nanotube composite airgel

[0062] 1. Preparation of PAS / MWCNT hybrid system

[0063] Take 15 g of polyamic acid, add 135 g of deionized water, dropwise add 7.14 g of triethylamine, and stir evenly with a magnetic force to obtain a PAS aqueous solution with a mass ratio of polyamic acid to water of 10:90. In addition, 0.6 g of multi-walled carbon nanotubes was weighed, and 150 g of deionized water was added. The mixture was ultrasonically dispersed on an ultrasonic cleaning machine for 2 h, and then ultrasonically dispersed on an ultrasonic cell pulverizer for 0.5 h, finally obtaining a uniformly dispersed multi-walled carbon nanotube aqueous suspension. The multi-walled carbon nanotube aqueous suspension was poured into the PAS aqueous solution, and magnetically stirred for 2 hours to obtain a uniform mixture system. In this system, the mass ratio of polyamic acid to water is 5:95, and the mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com