Zinc-aluminum-yttrium master alloy refiner and preparation method as well as application thereof

A master alloy and refiner technology, which is applied in the field of alloy materials, can solve the problems such as the decline of refinement effect and the "poisoning" of master alloy refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A zinc-aluminum-yttrium master alloy refining agent Zn-45Al-5Y (the mass percentage of Al in the alloy is 45%, the mass percentage of Y is 5%, and the rest is Zn), the preparation process is as follows. The purity of the pure zinc used in the preparation process is 99.9% or above, the purity of pure aluminum is 99.7% or above, and the purity of pure yttrium is 99.9% or above. Dispersion efficiency and dispersion effect in the body. The following examples and comparative examples all select the above-mentioned raw materials.

[0025] (1) According to the chemical composition and quality of Zn-45Al-5Y master alloy to be prepared, three raw materials of pure aluminum, pure zinc and pure yttrium were weighed respectively.

[0026] (2) Put the two raw materials of pure zinc and pure aluminum into the melting furnace to melt to 700-760°C, stir and mix thoroughly to obtain a zinc-aluminum alloy melt.

[0027] (3) Press pure yttrium into the zinc-aluminum alloy melt below the...

Embodiment 2

[0031] A zinc-aluminum-yttrium master alloy refining agent Zn-28Al-7Y, the preparation process is as follows.

[0032] (1) According to the chemical composition and quality of Zn-28Al-7Y master alloy to be prepared, three raw materials of pure aluminum, pure zinc and pure yttrium were weighed respectively.

[0033] (2) Put the two raw materials of pure zinc and pure aluminum into the melting furnace to melt to 700-760°C, stir and mix thoroughly to obtain a zinc-aluminum alloy melt.

[0034] (3) Press pure yttrium into the zinc-aluminum alloy melt below the liquid surface with a bell jar, react for 15 minutes, and then stir the alloy melt for 30 minutes to obtain a zinc-aluminum-yttrium alloy melt.

[0035] (4) The zinc-aluminum-yttrium alloy melt is poured into a mold, and after solidification, a zinc-aluminum-yttrium master alloy refiner is obtained.

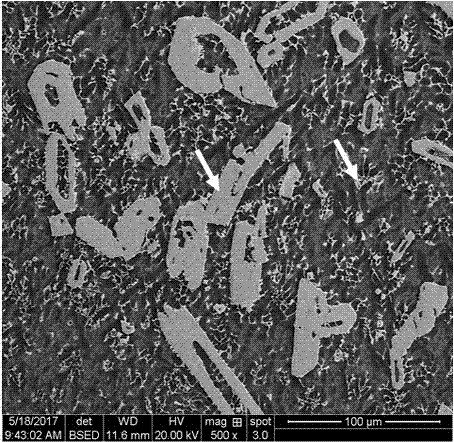

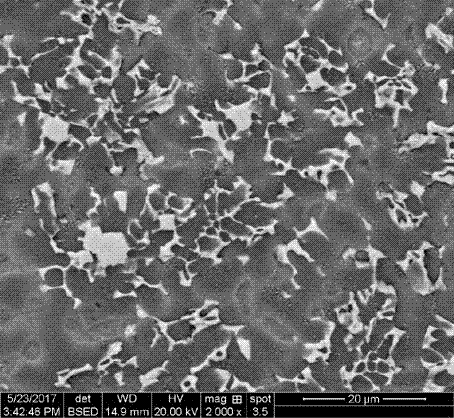

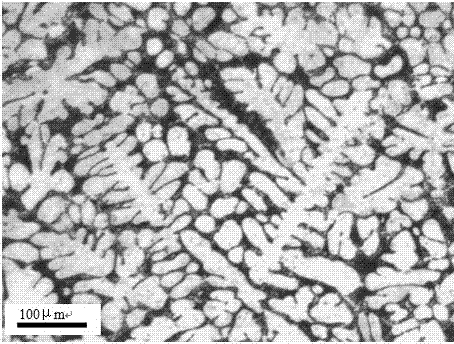

[0036]Analysis of the Zn-28Al-7Y master alloy refiner by scanning electron microscopy (EDX) found that, similar to the resul...

Embodiment 3

[0038] A zinc-aluminum-yttrium master alloy refining agent Zn-12Al-2Y, the preparation process is as follows.

[0039] (1) According to the chemical composition and quality of Zn-12Al-2Y master alloy to be prepared, three raw materials of pure aluminum, pure zinc and pure yttrium were weighed respectively.

[0040] (2) Put the two raw materials of pure zinc and pure aluminum into the melting furnace to melt to 700-760°C, stir and mix thoroughly to obtain a zinc-aluminum alloy melt.

[0041] (3) Pressing pure yttrium into the zinc-aluminum alloy melt below the liquid surface with a bell jar, reacting for 5 minutes, and then stirring the alloy melt for 10 minutes to obtain a zinc-aluminum-yttrium alloy melt.

[0042] (4) The zinc-aluminum-yttrium alloy melt is poured into a mold, and after solidification, a zinc-aluminum-yttrium master alloy refiner is obtained.

[0043] Analysis of the Zn-12Al-2Y master alloy refiner by scanning electron microscopy (EDX) found that, similar to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com