Novel Haff fireproof stay cable and manufacturing method thereof

A Haval-type, new technology, applied in the field of cables, can solve the problems of impact and inconvenience of the places where cables are used, and achieve the effect of simple replacement method and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

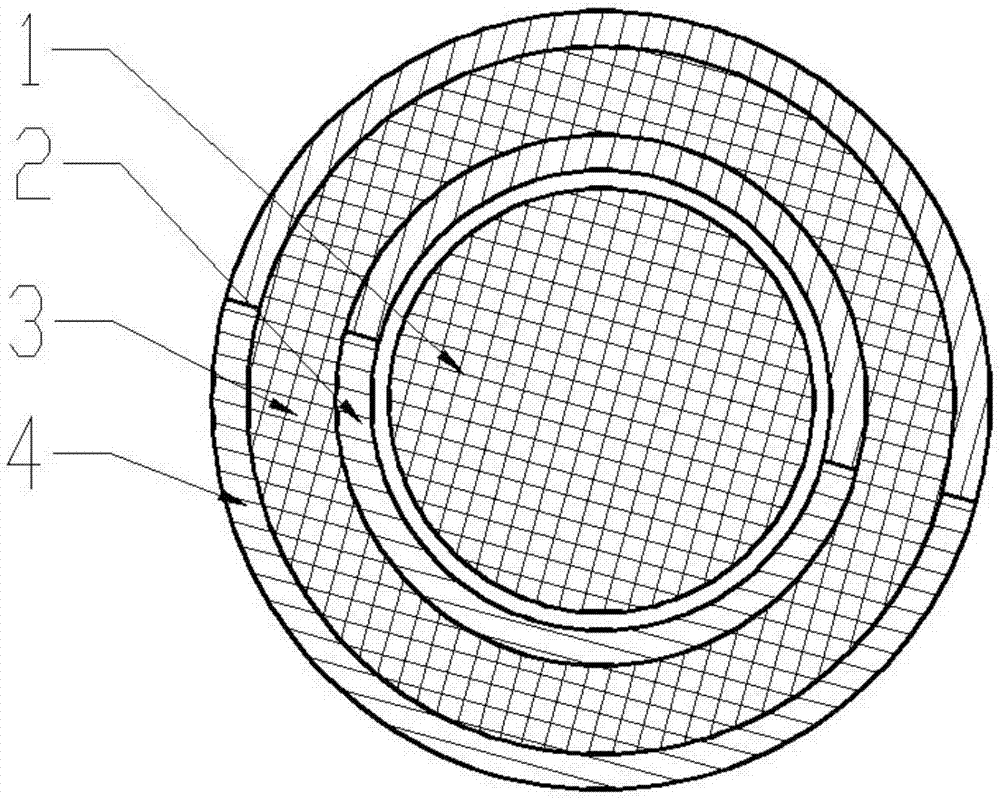

[0024] Such as figure 1 As shown, a new Haval-type fireproof cable includes a cable (1), an inner liner (2) and a fireproof material layer (3), and the outer layer of the cable (1) is wrapped with an inner liner (2), The inner liner (2) is detachably connected by two semicircular tubes, and the outer layer of the fireproof material layer (3) is wrapped with an outer liner (4), and the outer liner (4) is detachable by two semicircular tubes The fireproof material layer (3) is formed between the inner lining pipe (2) and the outer lining pipe (4) by pouring. The fireproof material is firmly installed and has high reliability.

[0025] Such as figure 1 As shown, the outer pipe of the inner liner (2) and the inner liner (4) are of Haval structure, with reliable installation and high connection strength.

[0026] The material of the fireproof material layer (3) is one of fireproof cotton, fireproof blanket, fireproof cloth, perlite filler or ceramic fireproof material, and the ma...

Embodiment 2

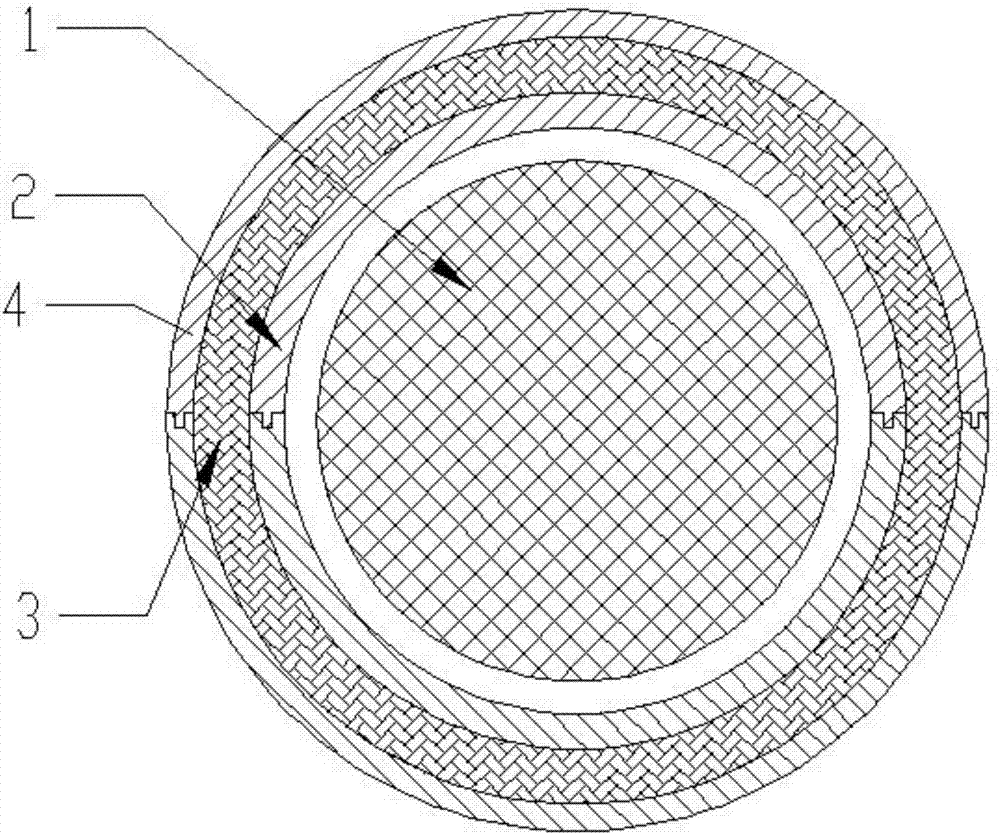

[0034] Such as image 3 As shown, the embodiment 2 of a kind of Haval type novel fireproof cable of the present invention, the difference between this embodiment and embodiment 1 is that, in this embodiment, the two semicircular pipes of the outer liner (4) adopt the method Lan (41) is connected and installed.

Embodiment 3

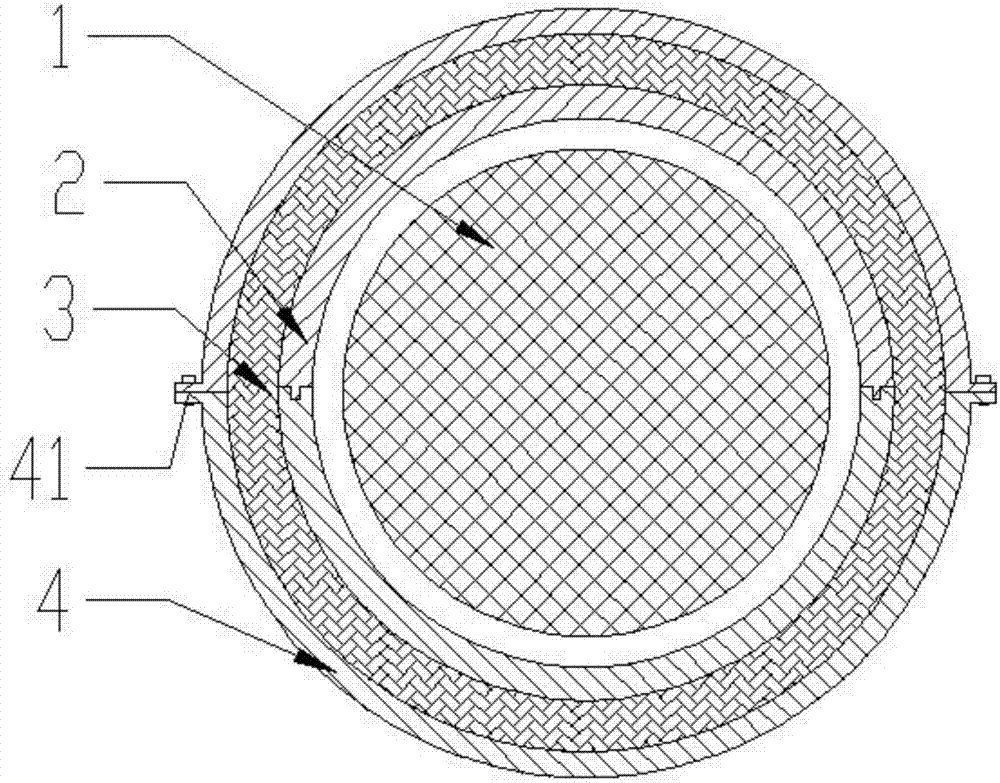

[0036] Such as Figure 4 As shown, the embodiment 3 of a kind of Haval type novel fireproof cable of the present invention, the difference between this embodiment and embodiment 1 is that, in this embodiment, the two semicircular pipes of the outer lining pipe (4) are made of steel Belt (42) binding connection installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com