A portable boiler cleaning device and its application method

A boiler cleaning and portable technology, applied in boiler cleaning devices, cleaning methods and utensils, descaling devices, etc., can solve the problems of cleaning dead corners, large boiler volume, and difficulty in cleaning in place, and achieve fast cleaning speed, small device size, Clean soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

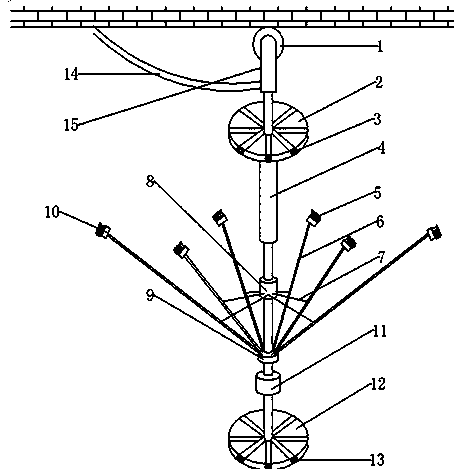

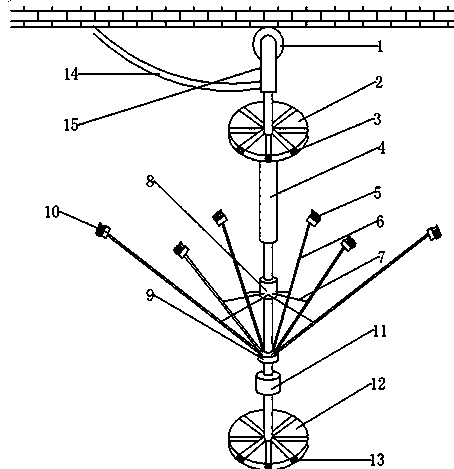

[0023] A portable boiler cleaning device, comprising a main telescopic rod 15 connected to the suspension wheel 1, a signal line 14 connected to the main telescopic rod 15, a rotating water spray plate 2 is installed under the main telescopic rod 15, and the side of the rotating water spray plate 2 is uniform Water pipe nozzles 3 are distributed, the auxiliary telescopic rod 4 is connected under the rotating water spray plate 2, the moving handle 8 is set on the auxiliary telescopic rod 4, the cleaning rod long bone 6 is connected to the moving handle 8 through the cleaning rod short bone 7, and the cleaning rod The top of the long bone 6 is equipped with a wire brush 5, and the bottom end of the cleaning rod long bone 6 is connected with the rotary motor 9. The bottom end of the wire brush 5 is equipped with a pressure sensor 10, and there is also a cleaning agent storage bin 11 under the rotary motor 9. , the bottom of the auxiliary telescopic rod 4 is also equipped with a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com