Hybrid drive waste heat utilization double-heat-pump system and control method

A hybrid power and control method technology, applied in heat pumps, refrigerators, refrigeration components, etc., can solve problems such as low utilization rate of waste heat, empty exhaust, and reduced heating demand, so as to improve energy utilization rate, increase utilization rate, The effect of achieving seasonal balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following specific embodiments will further clarify the present invention. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention.

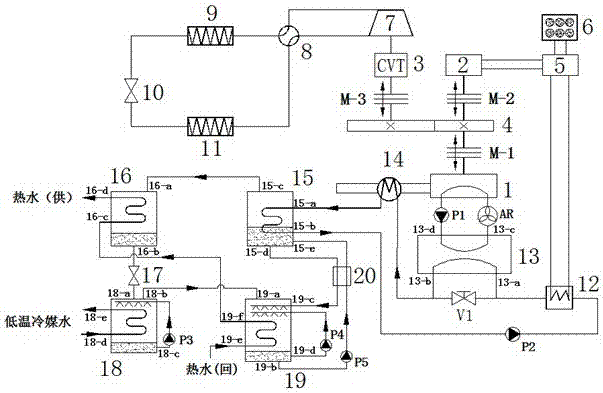

[0028] See figure 1 As shown, this embodiment provides a dual heat pump system using hybrid power to drive waste heat. Including: hybrid driven gas heat pump system, waste heat recovery water circulation system, absorption heat pump system;

[0029] The hybrid-driven gas heat pump system includes a gas engine 1, a motor 2, a continuously variable transmission device 3, a power coupler 4, an inverter 5, a lithium iron phosphate battery pack 6, a compressor 7, a four-way valve 8, and outdoor Unit 9, first throttle valve 10, indoor unit 11;

[0030] The waste heat recovery water circulation system includes an electric heater 12, a liner heat exchanger 13, a tail gas waste heat recovery device 14, a first circulating water pump P1, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com