Aspherical Surface Interferometry System and Method Based on Spatial Light Modulator Reference Surface

A technology of spatial light modulator and interferometric measurement, which is applied in measurement devices, instruments, optical devices, etc., can solve the problems of low detection accuracy of compensator, high cost of compensator, mechanical phase shift error, etc., and achieves low manufacturing accuracy requirements. , improve the stability, avoid the effect of the introduction of error sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

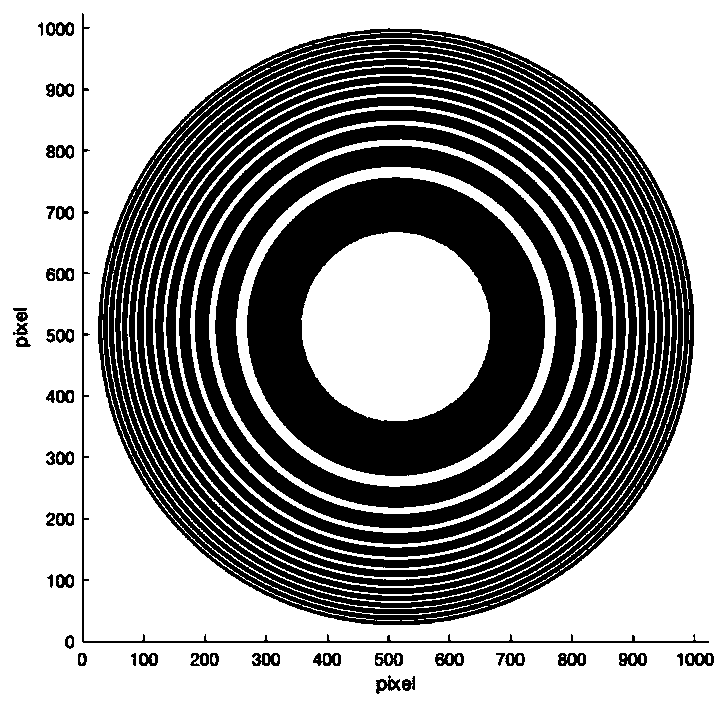

[0038] The specific parameters of the aspheric surface measured in this example are as follows: diameter 50.8mm; aspheric surface coefficient -1.01; quartic term coefficient of surface shape 1.27×10 -8 .

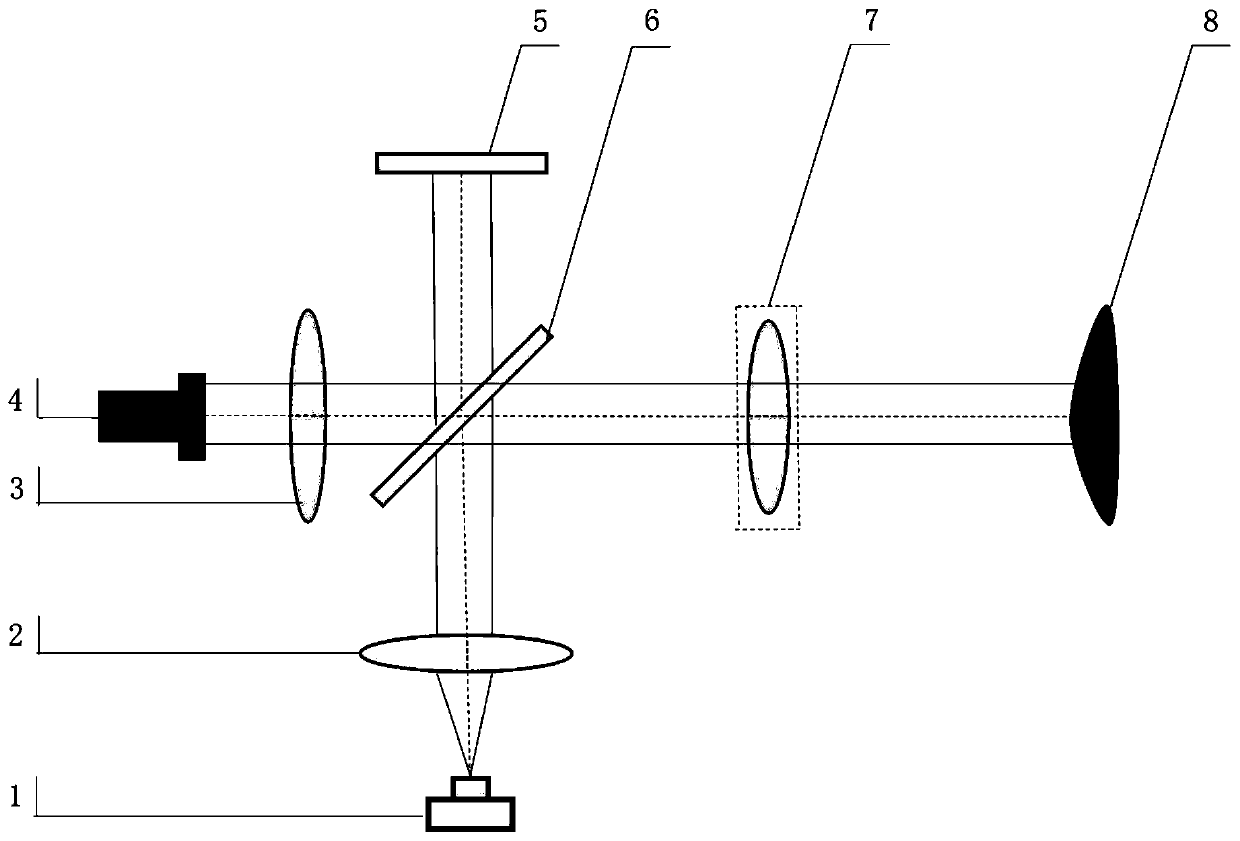

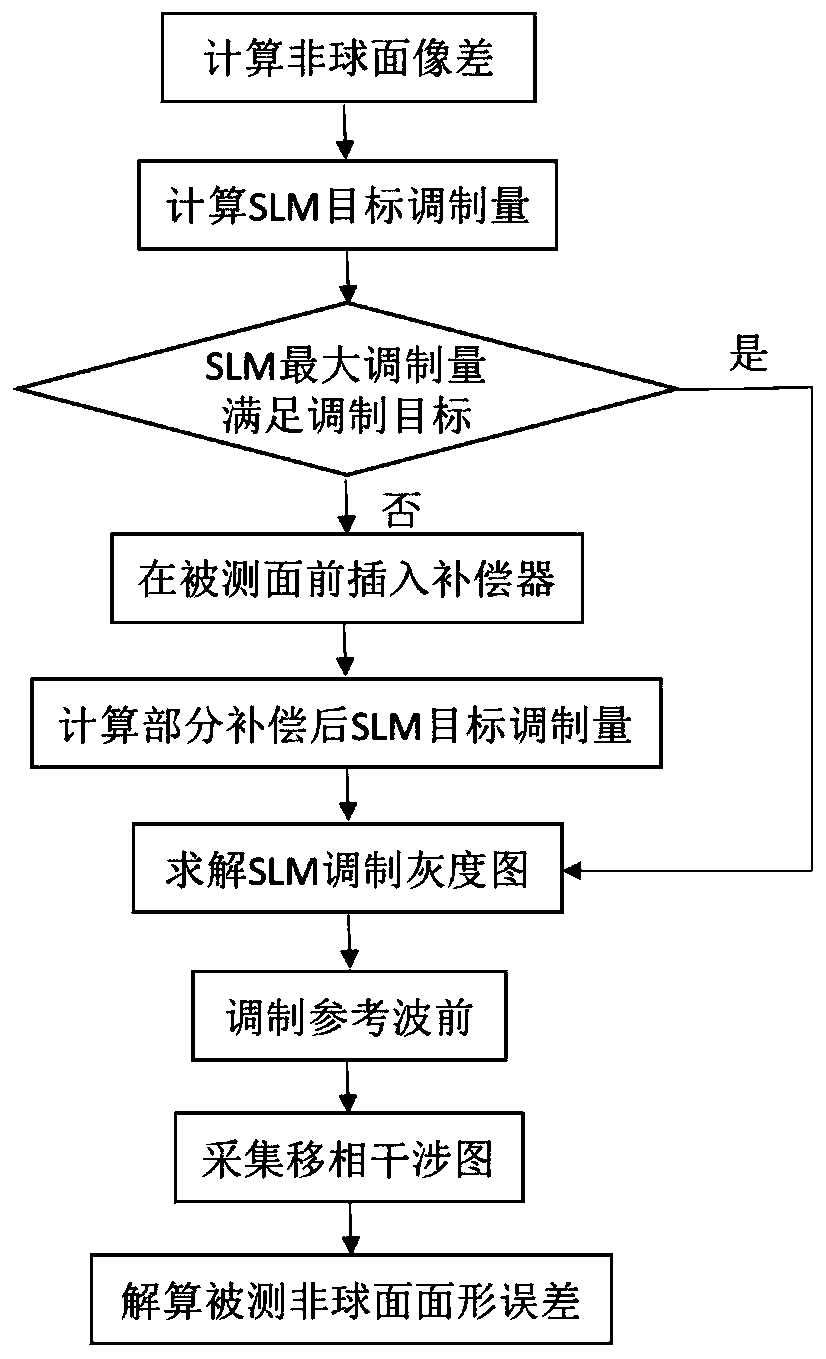

[0039] The aspheric interferometry system based on the spatial light modulator reference surface disclosed in this example includes a laser 4, a collimating objective lens 3, a beam splitter 6, an SLM reference mirror 5, an aspheric surface to be measured 8, an imaging objective lens 2, and a CCD detector 1 .

[0040] The optical path of the above-mentioned aspheric interferometry system is:

[0041] The parallel light formed by the laser beam emitted by the laser 4 is projected onto the beam splitter 6 after being collimated by the objective lens 3 , and then split into two beams after passing through the beam splitter 6 . A light beam returns to the beam splitter 6 after being passed through the SLM reference mirror 5. This beam is defined as a reference beam. In the ref...

example 2

[0052] The specific parameters of the aspheric surface measured in this example are as follows: diameter 50.8mm; vertex curvature radius -8000mm; aspheric surface coefficient -1.01; quadratic coefficient of surface shape 4.50×10 -5 ;Quaternary term coefficient 1.55×10 -8 ;Sixth order coefficient 1.1×10 -10 .

[0053] The aspheric interferometry system based on the spatial light modulator reference surface disclosed in this example includes a laser 4, a collimating objective lens 3, a beam splitter 6, an SLM reference mirror 5, a compensator 7, an aspheric surface to be measured 8, an imaging objective lens 2, CCD detector 1.

[0054] The optical path of the above-mentioned aspheric interferometry system is:

[0055] The parallel light formed by the laser beam emitted by the laser 4 is projected onto the beam splitter 6 after being collimated by the objective lens 3 , and then split into two beams after passing through the beam splitter 6 . A light beam returns to the beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com