Method for mining surface monitoring in mountainous area based on measurement robot and close-range photogrammetry

A technology for measuring robots and close-range photography, applied in measuring instruments, measuring devices, surveying and navigation, etc., can solve the problems of difficulty in reflecting the law of continuous movement and deformation, low precision of close-range photogrammetry technology, and large field workload, etc. The effect of moving deformation omissions, avoiding errors, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail through specific embodiments below.

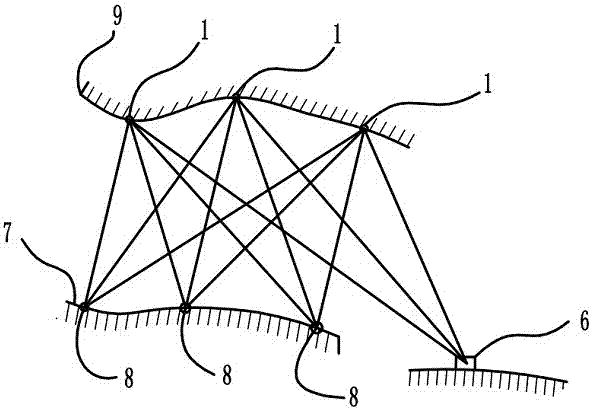

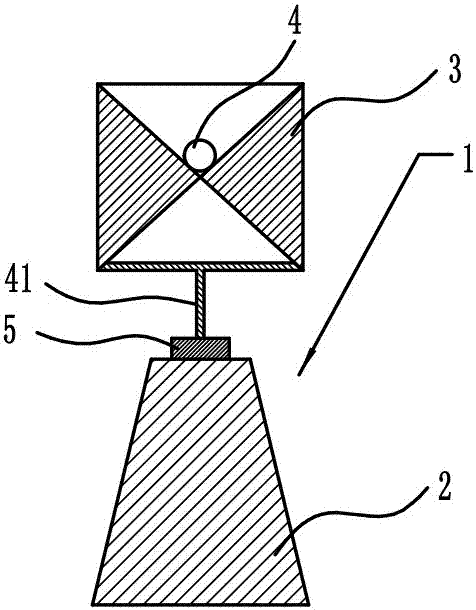

[0034] The reference signs in the drawings of the description include: monitoring station 1, observation pier 2, target 3, SMR prism 4, base 5, reference station 6, stable area 7, photographing station 8, deformation area 9, leveling cylinder 21 , Telescopic cylinder 22, wiping rod 23, angle sensor 24, hair brush 25, controller 26, support rod 41.

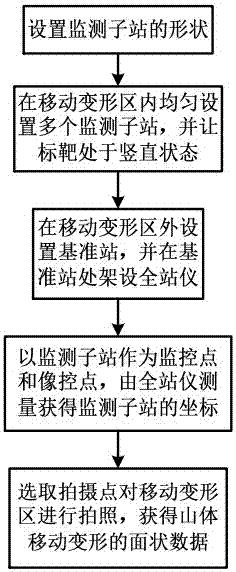

[0035] Such as image 3 The structure of the monitoring station 1 shown, and as figure 1 and figure 2 The surface monitoring method of mountainous mining based on measuring robot and close-range photogrammetry is shown, including the following contents:

[0036] S1, first select a plurality of monitoring stations 1, and bury 80% of the monitoring stations 1 evenly in the moving deformation area 9, and all the monitoring stations 1 in the moving deformation area 9 are not located on the same straight line or on the same plane, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com