System calibration method of gas flowmeter

A technology of gas flowmeter and calibration method, which is applied in the direction of liquid/fluid solid measurement, test/calibration device, measurement device, etc., and can solve the problems that the detection accuracy cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

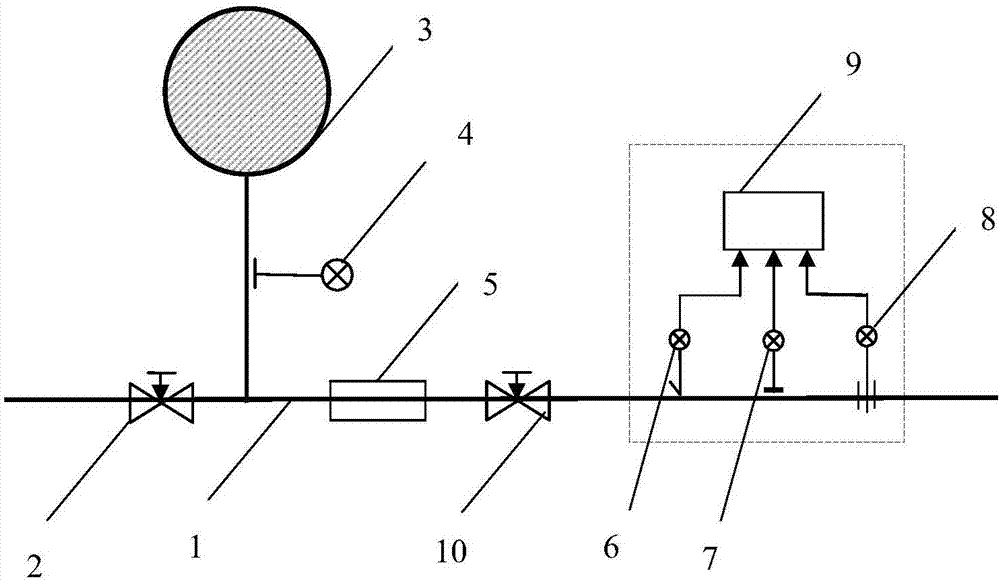

Image

Examples

Embodiment Construction

[0021] Specific implementation examples

[0022] Taking the gas flow meter of the hydrogen flow rate of our company as an example, the specific implementation method is stated, and the specific calibration steps are as follows:

[0023] 1. Choose a 0.05-level digital high-precision standard pressure gauge to replace the original storage tank gas capacity pressure gauge.

[0024] 2. Inflate the gas tank and the pipe network. When the pressure P of the gas tank rises to the maximum working pressure Pmax, the two-position valve for supplying gas to the pipe network will be closed; at the same time, record the pressure value of the gas tank Pmax and the value of the calibrated gas flow accumulator value at this time. In this implementation case, the pressure value of the gas tank is Pmax=1.5MPa, and the measured value Q1 of the calibrated gas flow accumulator=15536.6Nm 3 .

[0025] 3. The stored gas of the total gas capacity starts to supply gas to the user. When the pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com