High-suction-controlled roadbed material wetting-drying cycle testing device and testing method thereof

A technology of dry-wet cycle and subgrade materials, which is applied in the field of geotechnical engineering, can solve the problems of application limitations, and achieve the effects of precise moisture content control, simple materials, and small soil disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The shapes, sizes, proportions, etc. of the components shown in the drawings of this specification are only for illustration purposes, and are not limitations on the conditions for the implementation of the present invention, and have no technical significance. Any structural modification, adjustment of size ratio, On the premise of not affecting the functions of the present invention, all should still fall within the scope of the technical content disclosed in the present invention.

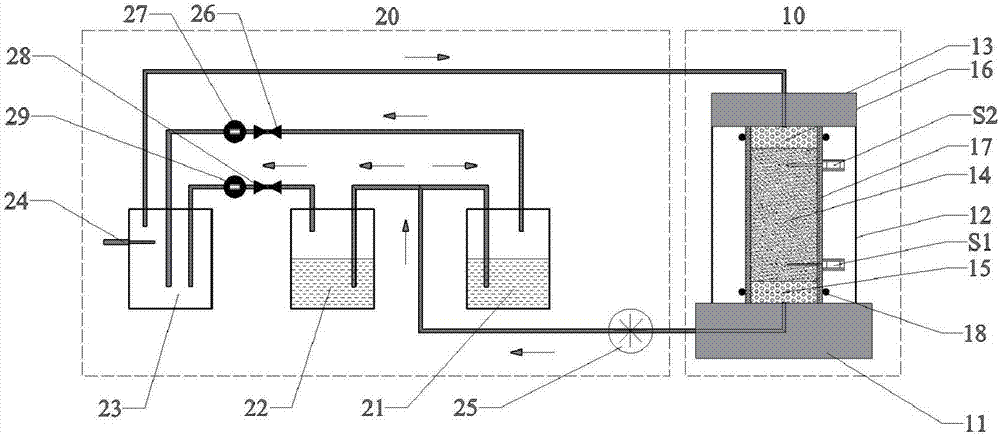

[0038] Such as figure 1As shown, a dry-wet cycle test device for roadbed materials with high suction control includes a test chamber 10 for accommodating samples and a suction control device 20 .

[0039] 1) Test chamber 10:

[0040] The test chamber 10 includes a base 11, an outer wall 12, an upper cap 13, and a soil sample 14, a bottom permeable stone 15, a top permeable stone 16, a rubber membrane 17, an O-ring 18, a bottom soil moisture sensor S1, and a top soil sample. Moisture sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com