Coating processing method, computer storage medium, and coating processing device

A processing method and technology for processing devices, which are applied to devices for applying liquid to surfaces, pre-treatment surfaces, coatings, etc., can solve problems such as deterioration of uniformity of coating films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

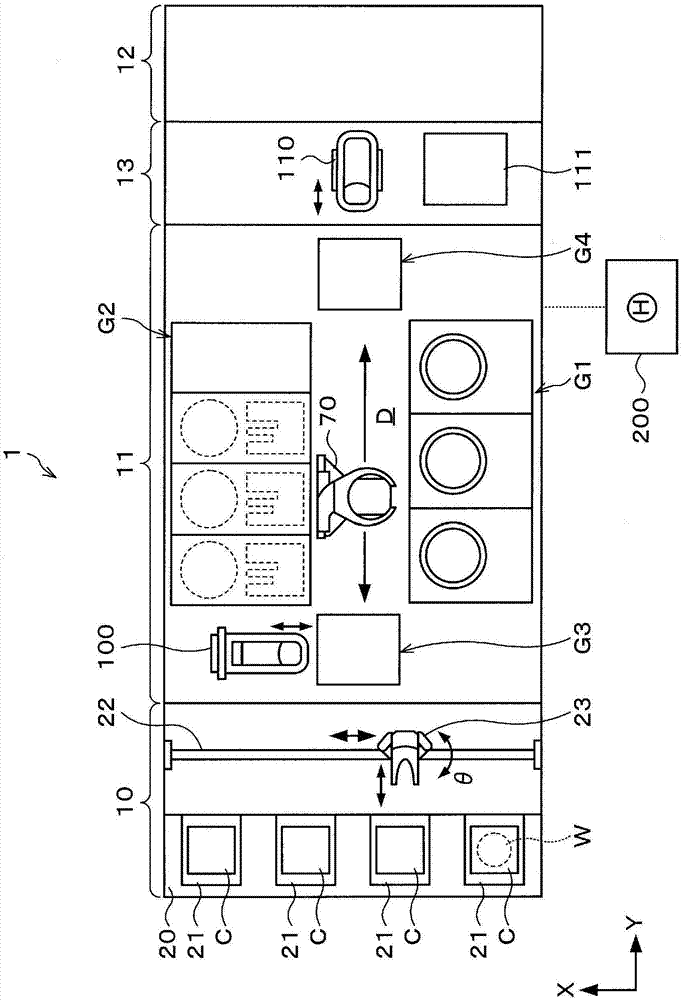

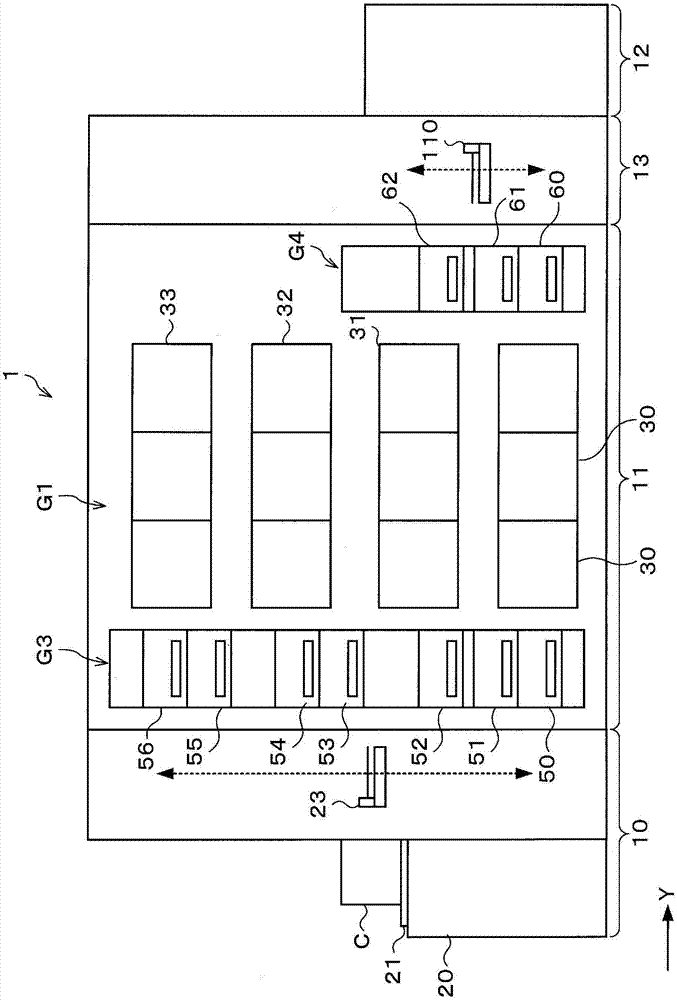

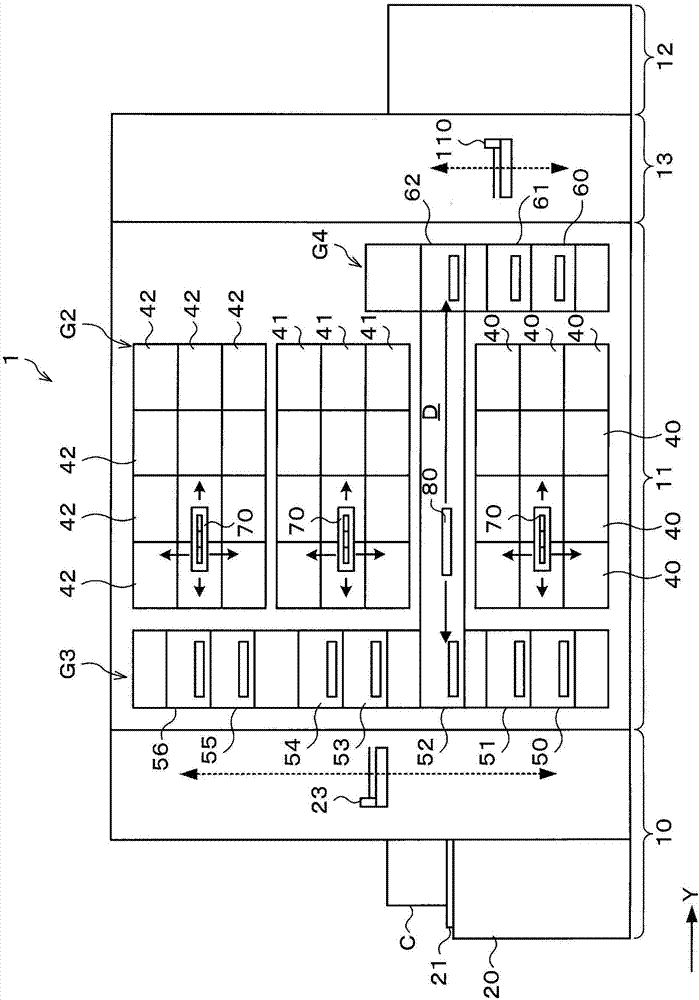

Examples

Embodiment

[0108] As an example, an ArF resist with a viscosity of 1.0 cP was used as the resist liquid R, and cyclohexanone was used as the solvent Q, and a test was carried out by coating the resist liquid on the wafer W by the coating treatment method of this embodiment. . At this time, the supply amount of the resist liquid R was changed between 0.20 mL and 0.30 mL at 0.05 mL intervals, and the wafer W was placed on the Figure 7 time t 1 ~t 2 The time for rotating at a rotation speed of 2000 rpm was changed to 2 seconds, 5 seconds, and 8 seconds to change the film thickness of the first liquid film M1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com