High-purity tungsten hexacarbonyl for solid source delivery

一种六羰基钨、来源的技术,应用在固体来源材料领域,能够解决腐蚀微电子器件、激发替代钨来源试剂寻求、影响来源材料的性能及工艺可重复性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example I

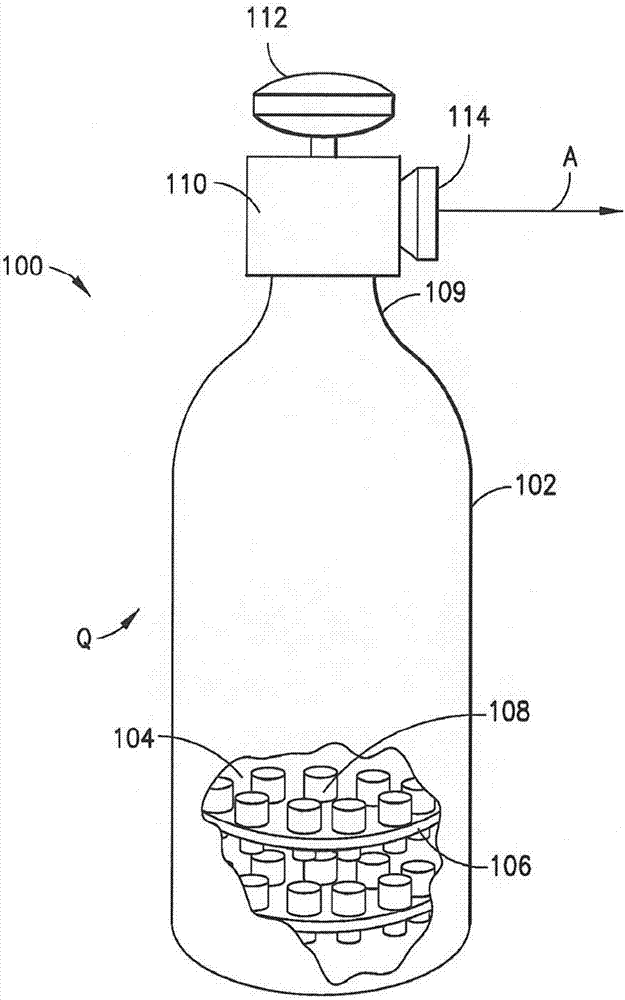

[0055] Tungsten hexacarbonyl vaporization tests were performed to evaluate solid source materials for tungsten hexacarbonyl.

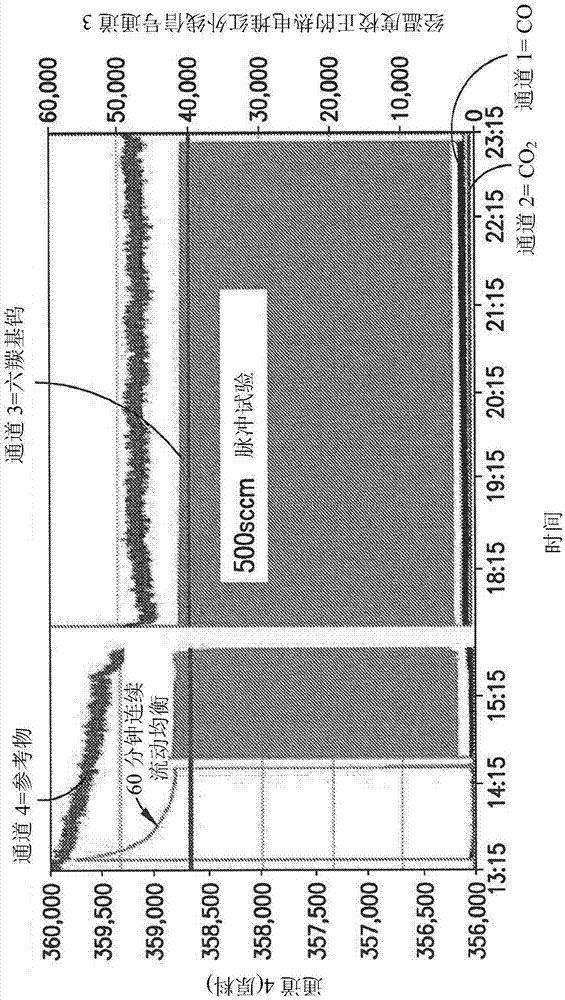

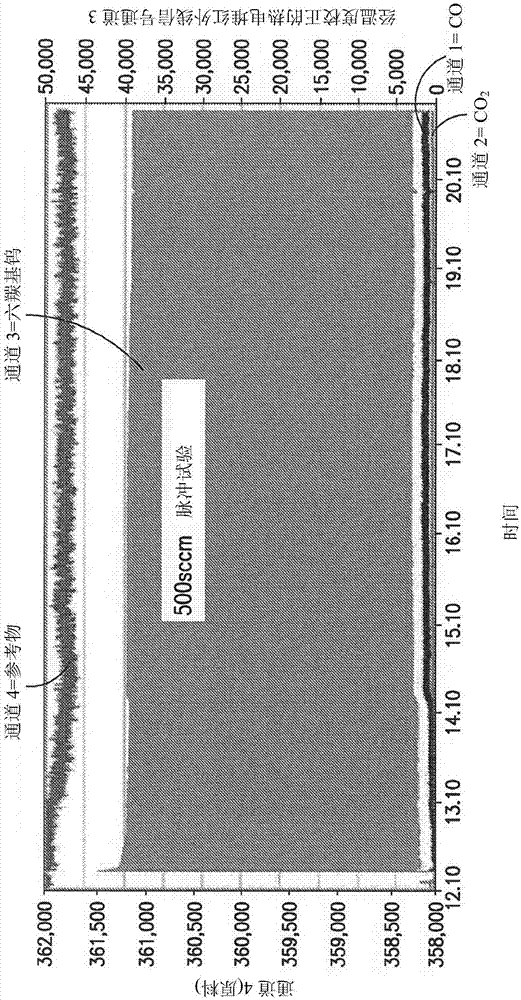

[0056] A thermopile infrared (TPIR) detector was used to monitor vapors generated during operation of a vaporizer ampoule containing tungsten hexacarbonyl material. The TPIR detector utilizes a 1-meter linear unit configured with a reference channel, a channel for "free" carbon monoxide (CO), a channel for carbon dioxide (CO 2 ), and a channel configured for CO coordinated to the metal center at 5.0 microns to be able to detect W(CO) in the 5.0 micron filtered channel 6 and Mo(CO) 6 both.

[0057] The first vaporizer vessel (designated NSI Ampoule #1) was operated with granular tungsten hexacarbonyl material having the particle size distribution shown in Table 1 below.

[0058] Table 1

[0059] Granularity (mm)

Test 1(g)

Test 1(%)

Test 2(g)

average (g)

average(%)

>1.4

20.18

19.05

20.25

20.22

19.59 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com