Device and method for processing primarily flat workpieces

A technology for workpieces and equipment, applied in metal processing, machining/deformation, object supply, etc., can solve problems such as unfavorable aspect ratio, undesired rotation of workpieces, etc., and achieve the effect of high orientation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

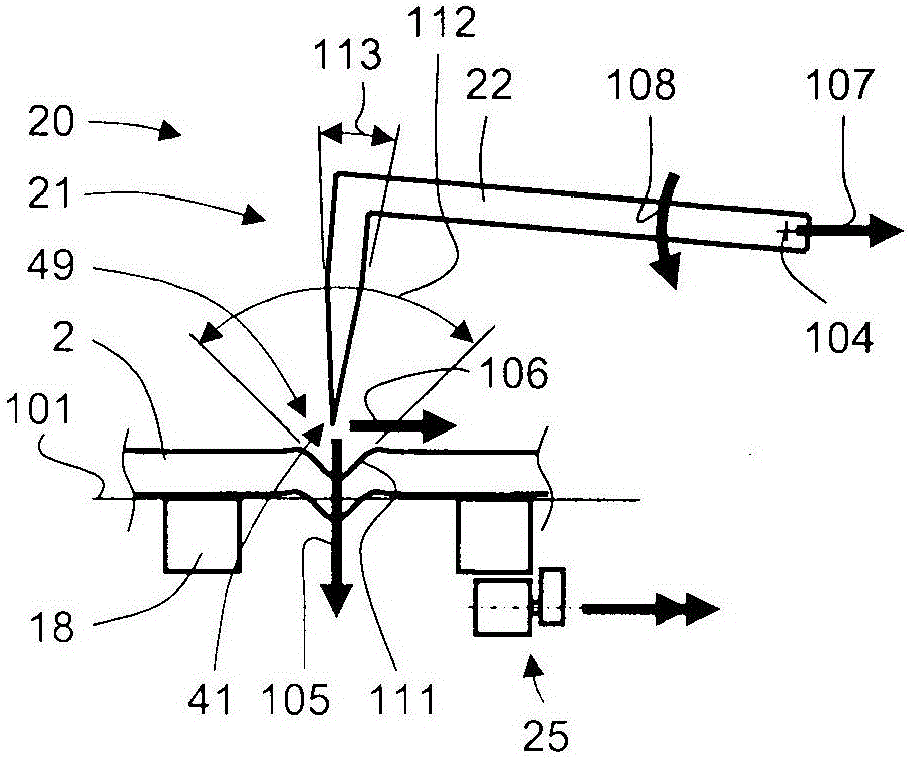

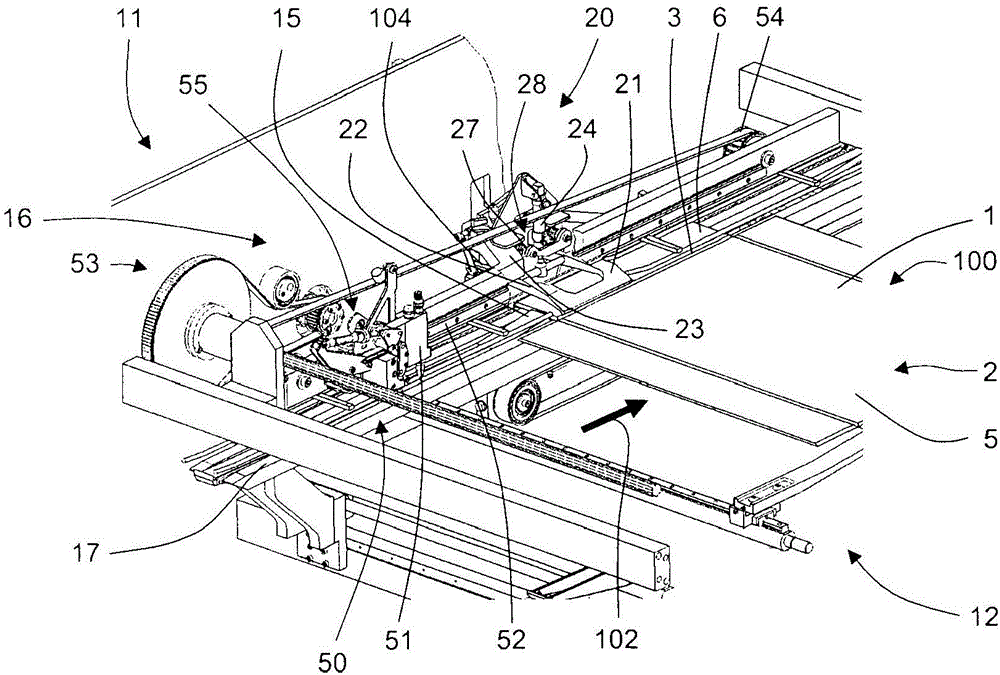

[0029] exist image 3 The machine for producing dimensionally stable boxes from cardboard cut-out blanks 2 , partially shown in the middle, comprises a plurality of devices 5 , 12 , 20 , 50 arranged in a common frame 11 for Make the cardboard cutting blank 2 stand up and fix. The cardboard blank 2 has a rectangular base 5 and on each side of the base a wall section 6 connected to the base by a v-shaped groove 3 .

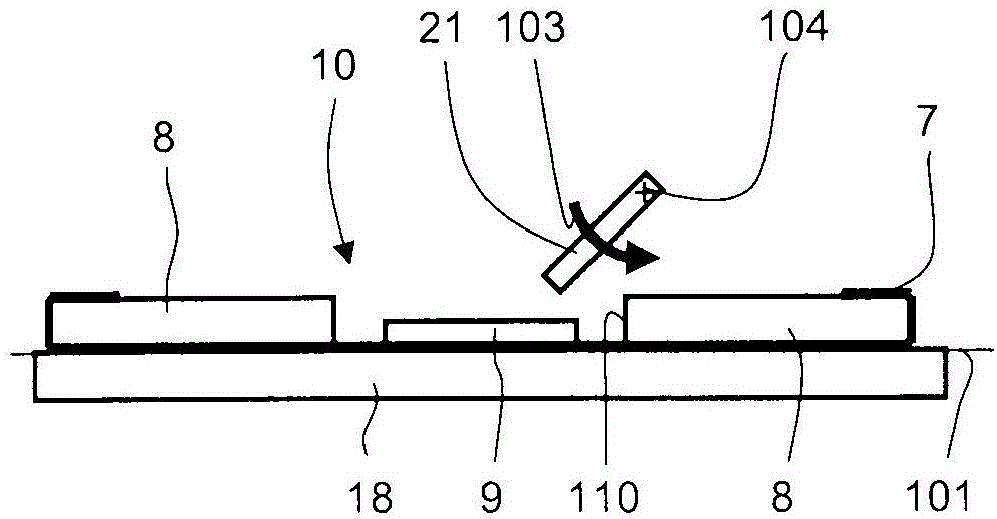

[0030]The transport device 12 introduces an individual cardboard cut web 2 into the gluing device 50 in a conveying direction 102 that rises with respect to the horizontal direction and, after applying the adhesive, transports the cardboard cut web 2 in the same direction 102 . A device (not shown) for erecting the wall 6 into a box is introduced from the gluing device 50 . Here, the cardboard cut-out blanks 2 are placed on a plurality of support rails 18 parallel to the conveying direction 102 , which form the conveying plane 101 . Above the conveying plane 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com