Apparatus and method for shielding a wafer from charged particles during plasma etching

一种等离子体、蚀刻设备的技术,应用在电路、放电管、电气元件等方向,能够解决破坏静电卡盘、除去晶片花费时间、减小系统产量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

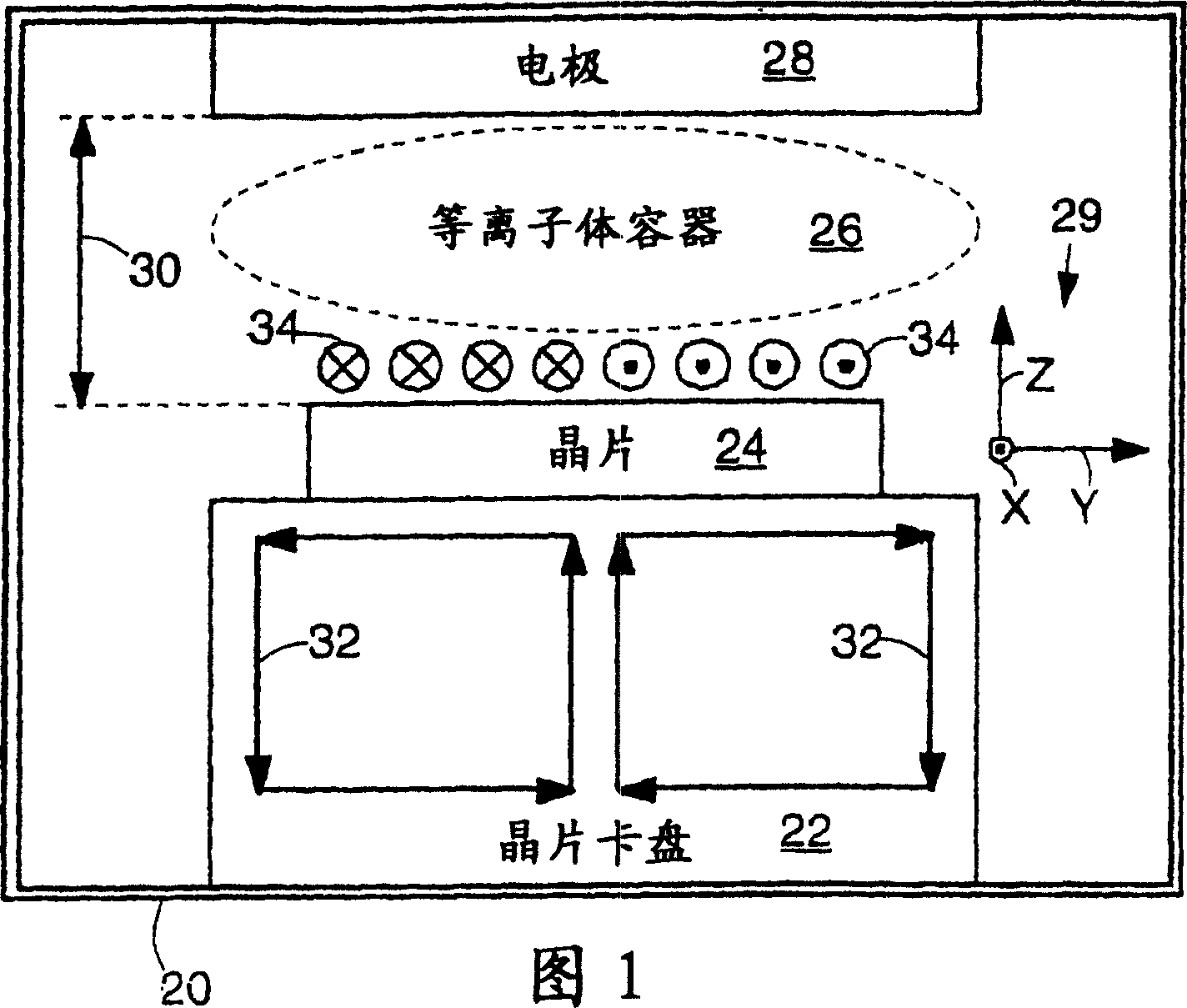

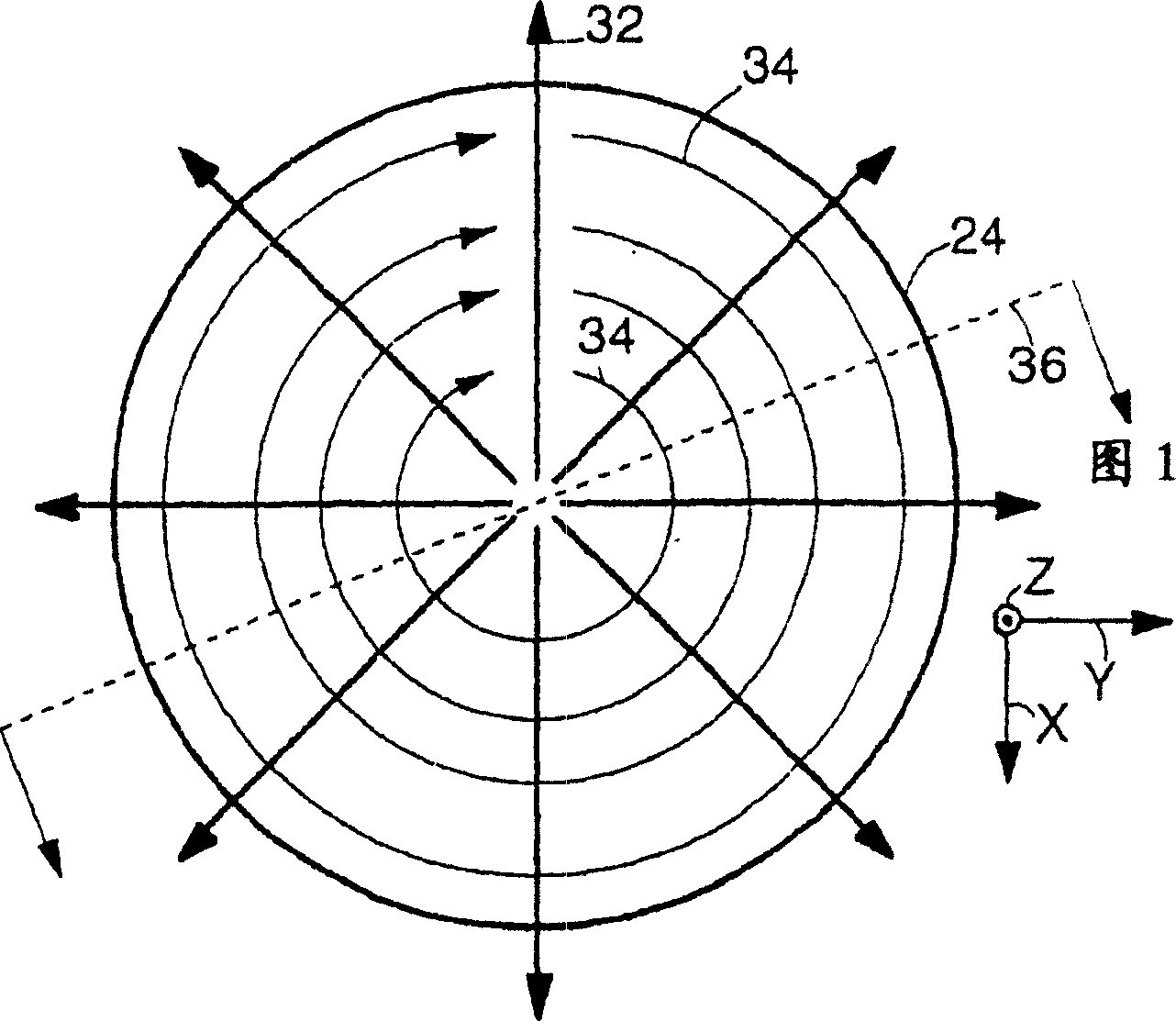

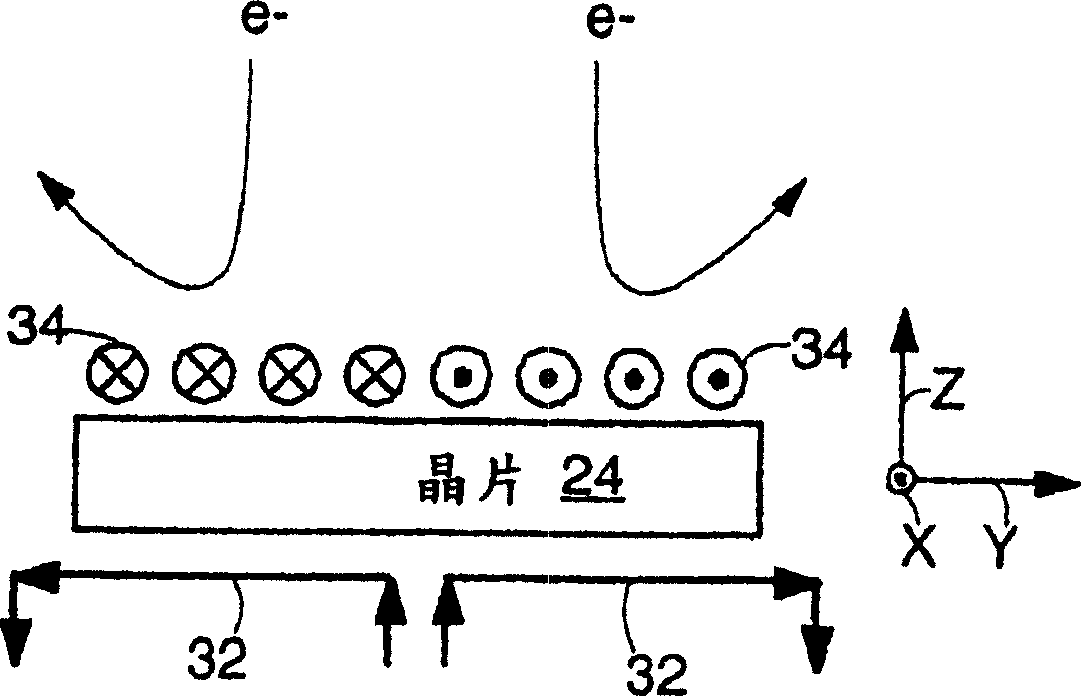

[0039] The present invention provides a plasma etching system that can shield wafers from charged particles. The plasma etch system has a wafer chuck with magnets within the chuck. The magnets generate a magnetic field parallel to the wafer surface. This magnetic field reflects plasma electrons moving towards the wafer. Varying the strength of the magnetic field provides control over the amount of charged particles attached to the wafer. This magnetic field can adjust the anisotropy / isotropy of the plasma etch process and can prevent damage to the wafer during chamber coating. In fact, for certain plasma etch chemistries combined with high magnetic fields, it is possible to make the etch almost completely isotropic. In glazing, the magnetic field blocks the charged particles, which almost completely prevents the glazing plasma from damaging the wafer.

[0040]Figure 1 shows a side view of one embodiment of the invention having a wafer chuck 22 within a chamber 20, a wafer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com