Metal crown lid with gray level identification code

A technology of identification codes and crown caps, which is applied in the field of crown caps with identification codes, can solve the problems of large environmental impact, uneven surface of the cap body, and affect the appearance, so as to achieve smooth and beautiful appearance, increase engraving speed, and meet high-speed requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

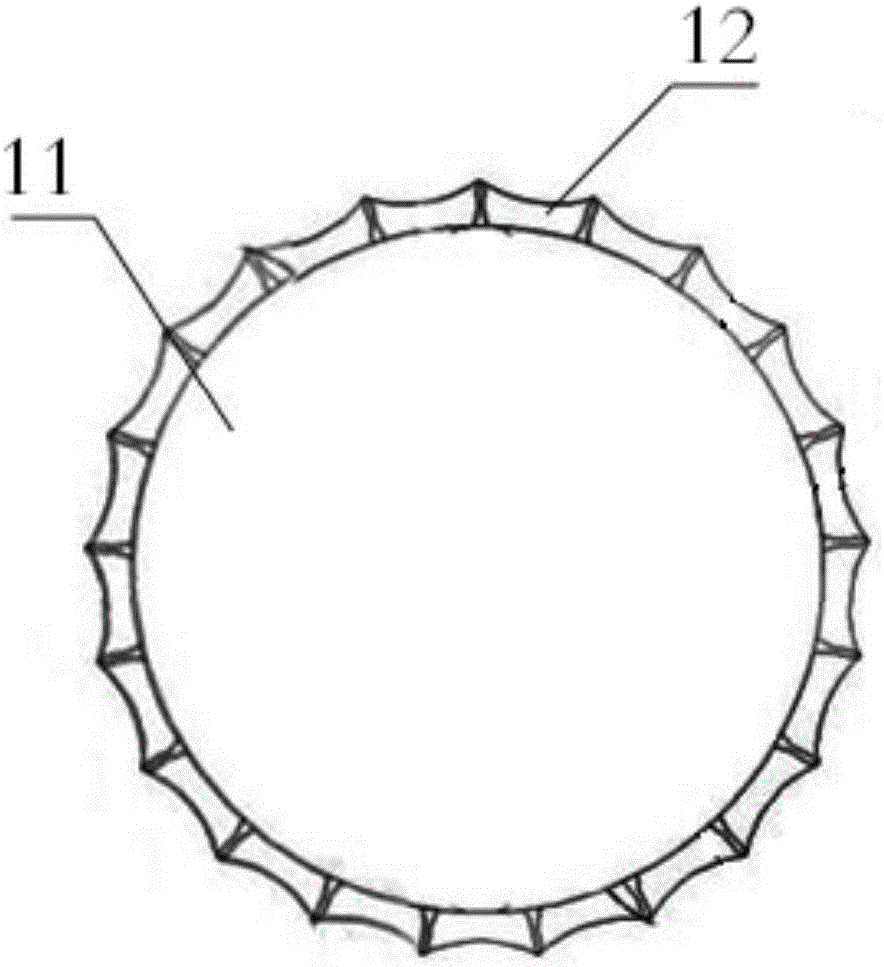

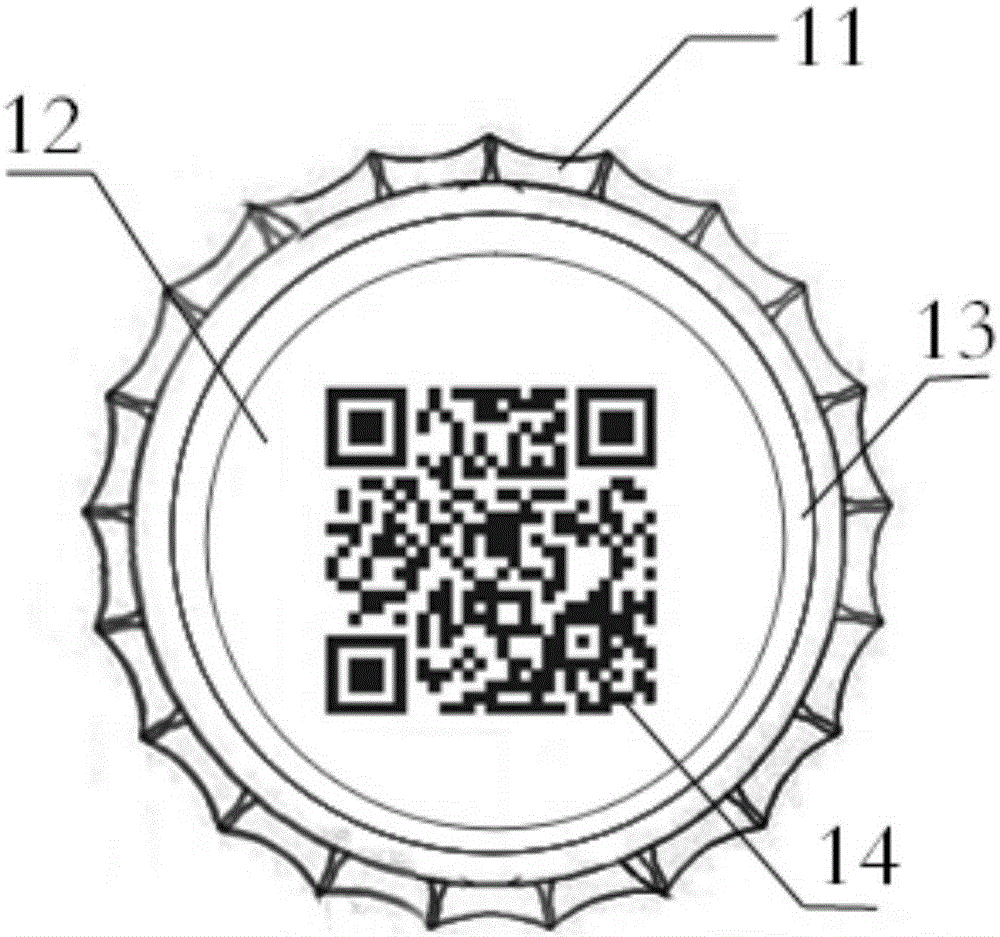

[0035] combine figure 1 and figure 2 It can be seen that, in this embodiment, the structure of the crown cover includes a circular top 11 and a skirt 12 integrally formed with the top 11, which is formed in a photon-sensitive ink layer arranged on the inner side of the top 11 (that is, the back of the crown) There is a first grayscale identification code 14, and a sealing injection molding gasket 13 made of silicone material is also arranged on the inner side of the top 11. The upper surface of the sealing injection molding gasket 13 is pasted on the surface of the photon-sensitive ink layer arranged on the inner side of the top 11 through an adhesive layer .

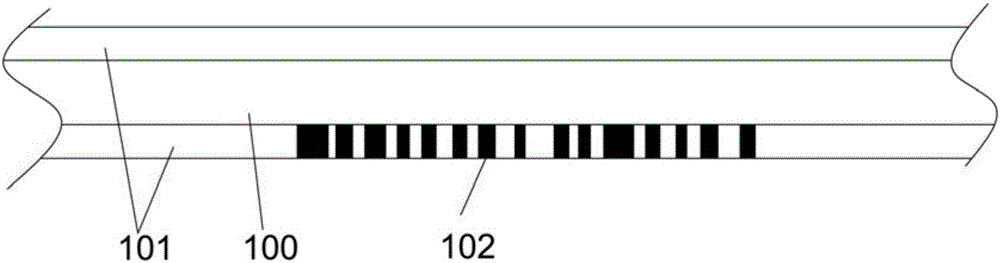

[0036] Specifically, as Figure 3a and Figure 3b As shown, the top 11 and the skirt 12 respectively include a substrate 100 and photon-sensitive ink layers 101 disposed on both sides of the substrate 100 . Wherein, the photon-sensitive ink layer disposed on the inner side of the substrate 100 is exposed and forms ...

no. 2 example

[0042] Such as Figure 5 and Figure 6 As shown, the structure of the second embodiment is basically the same as that of the first embodiment, the difference is that: not only the first grayscale identification code 24 is formed on the inner side of the top 21 (that is, the back side of the crown cover), but also on the outer side of the top 21 (ie the front of the crown cover) forms the second grayscale identification code 25 .

[0043] Specifically, as Figure 7a and Figure 7b As shown, the top 21 and the skirt 22 respectively include a substrate 200 and photon-sensitive ink layers 201 disposed on both sides of the substrate 200 . Wherein, the photon-sensitive ink layer arranged on the inner side of the substrate 200 is exposed and forms the first grayscale identification code 24 (such as Figure 7a shown) or the photon-sensitive ink layer disposed on the inner side of the substrate 200 is covered by the inner coating 203 after the first grayscale identification code 24...

no. 3 example

[0049] Such as Figure 10 to Figure 12 As shown, the structure of the third embodiment is basically the same as that of the crown caps provided by the first embodiment and the second embodiment, the difference is that a first gray scale mark is provided on the inner side of the crown cap skirt 32 Code 36. Since the top 31 and the skirt 32 of the crown are integrally formed, the skirt 32 of the crown has the same structure as the top 31, which includes a substrate and photon-sensitive ink layers arranged on both sides of the substrate, wherein the substrate is arranged on the substrate The photon-sensitive ink layer on the inner side is exposed and forms the first grayscale identification code 36 (such as Figure 11 shown). Due to the limited size of the skirt, the first gray-scale identification code 36 set on the inner side of the skirt 32 is recommended to use a short character code composed of letters and numbers, and a combination of words and letters or numbers can also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com