Jet-flow tube electro-hydraulic servo valve driven by piezoelectric ceramic

A piezoelectric ceramic drive, piezoelectric ceramic technology, applied in servo motor components, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve the problem of large inertia of the jet tube, slow dynamic response, and complex torque motor processing technology and other problems, to achieve the effect of high control accuracy, fast dynamic response, and improved dynamic response speed and control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

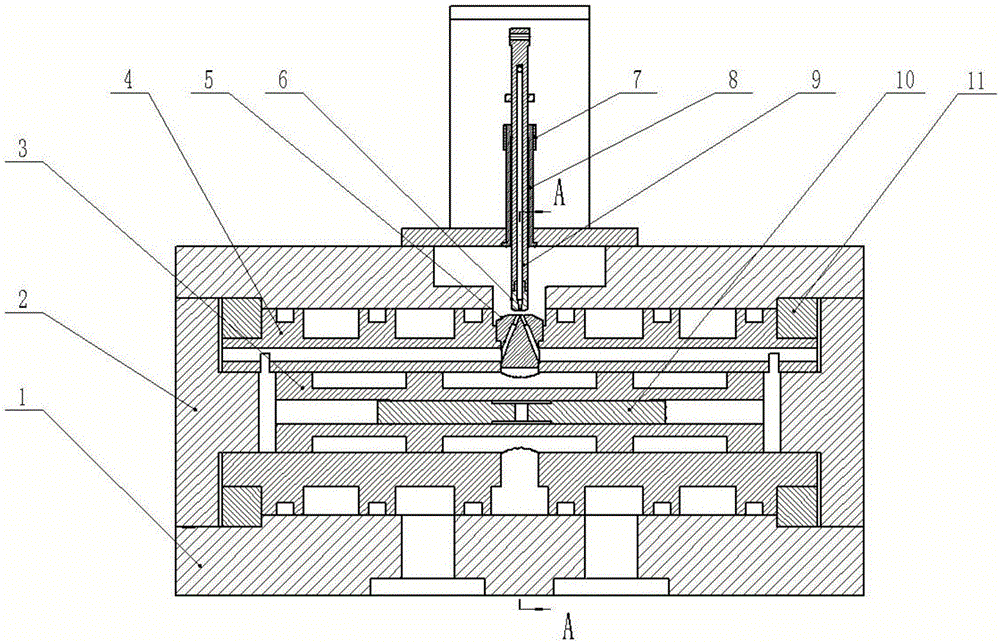

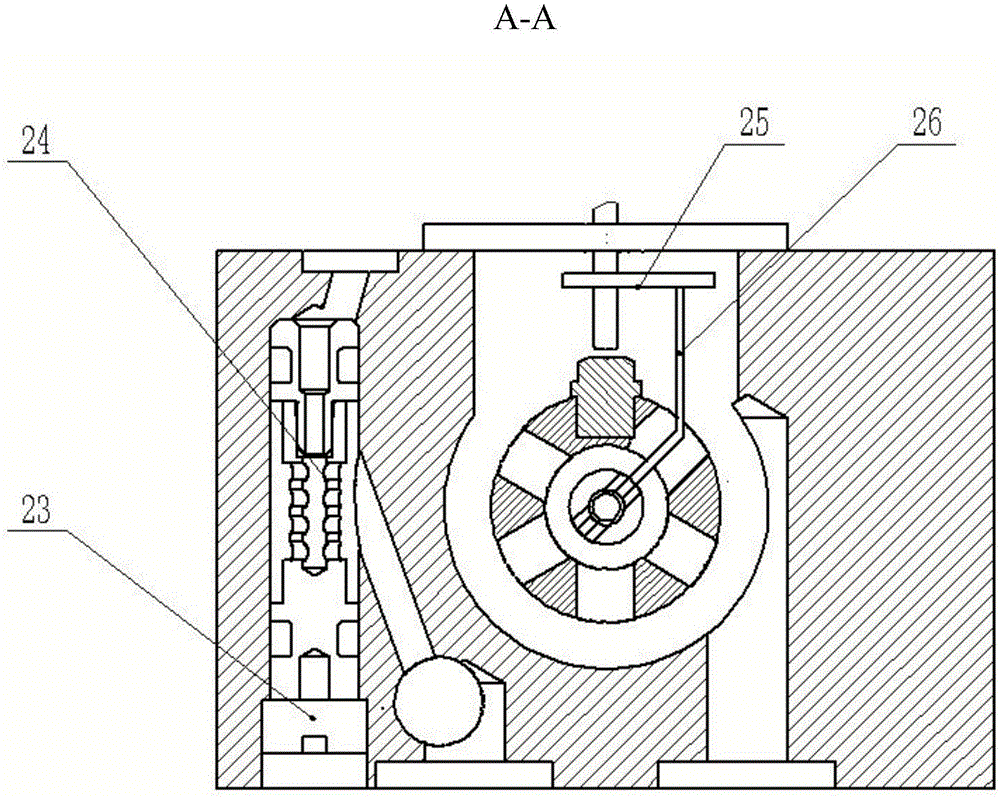

[0021] in figure 1 , figure 2 , image 3 As shown in the schematic diagram of the present invention, the piezoelectric ceramic driven jet tube electro-hydraulic servo valve includes a main valve, a piezoelectric ceramic pre-stage, and a feedback rod. The piezoelectric ceramic pre-stage is fixed with the main valve body by screws, and the nozzle of the jet tube is aligned with the receiver. One end of the feedback rod is connected with the main valve core through the clamping screw, and the other end of the feedback rod is connected with the jet Pipe connection.

[0022] The main valve includes a valve body 1, a valve sleeve 4, a valve core 3, a receiver 5, a clamping screw 10, a locking ring 11, an oil filter 24, a plug 23, and an end cover 2. The inner hole of the valve body 1 is provided with a valve sleeve 4, and the inner hole of the valve body 1 is provided with a locking ring 11 for fixing the valve sleeve 4. A sealing ring is arranged in the upper sealing groove of the v...

Embodiment 2

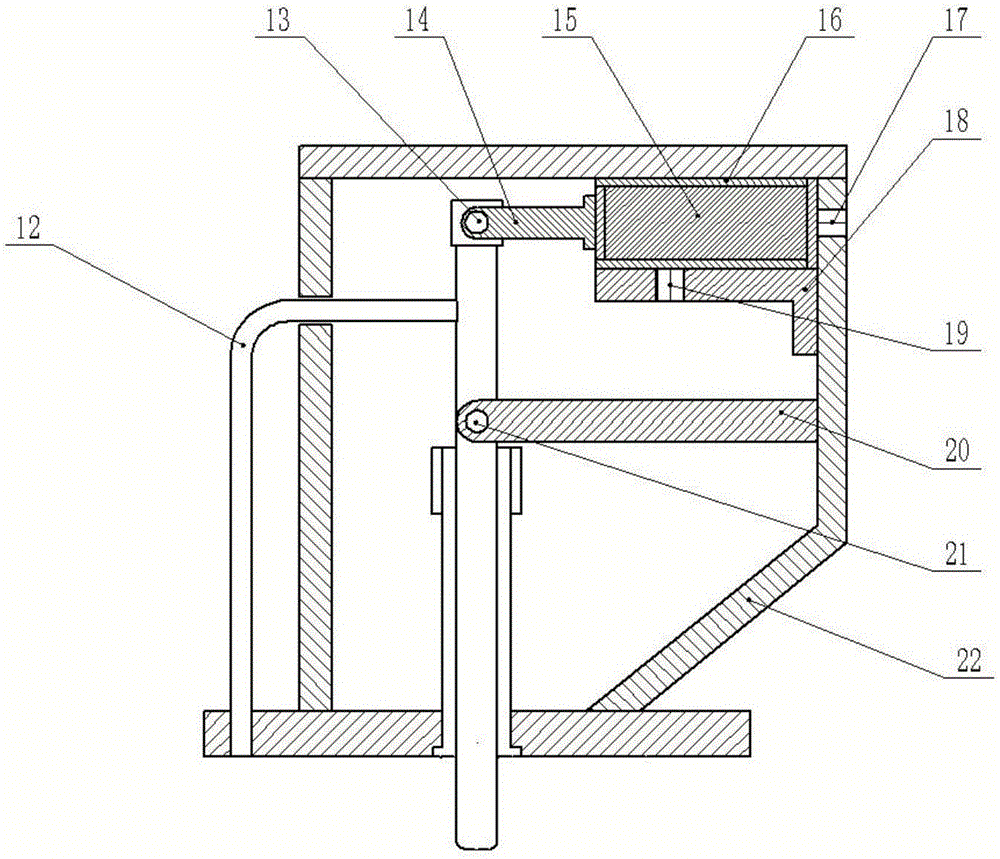

[0028] in figure 1 , figure 2 , Figure 4 As shown in the schematic diagram of the present invention, the piezoelectric ceramic driven jet tube electro-hydraulic servo valve includes a main valve, a piezoelectric ceramic pre-stage, and a feedback rod. The piezoelectric ceramic pre-stage is fixed with the main valve body by screws, and the nozzle of the jet tube is aligned with the receiver. One end of the feedback rod is connected with the main valve core through the clamping screw, and the other end of the feedback rod is connected with the jet Pipe connection.

[0029] The main valve includes a valve body 1, a valve sleeve 4, a valve core 3, a receiver 5, a clamping screw 10, a locking ring 11, an oil filter 24, a plug 23, and an end cover 2. The inner hole of the valve body 1 is provided with a valve sleeve 4, and the inner hole of the valve body 1 is provided with a locking ring 11 for fixing the valve sleeve 4. A sealing ring is arranged in the upper sealing groove of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com