Stainless steel television frame forming process and equipment

A molding process and molding equipment technology, which is applied in the field of stainless steel TV frame molding technology and equipment, can solve problems such as easy rebound, large R angle at the appearance of bending, and poor product straightness, and achieve fast speed, good cutting quality, and heat resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

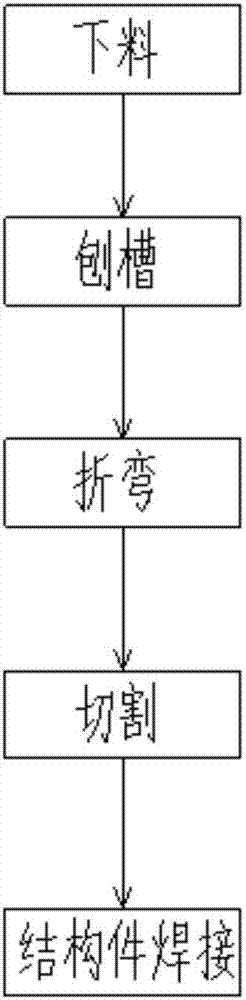

[0040] like figure 1 As shown, the stainless steel TV frame forming process includes the following steps:

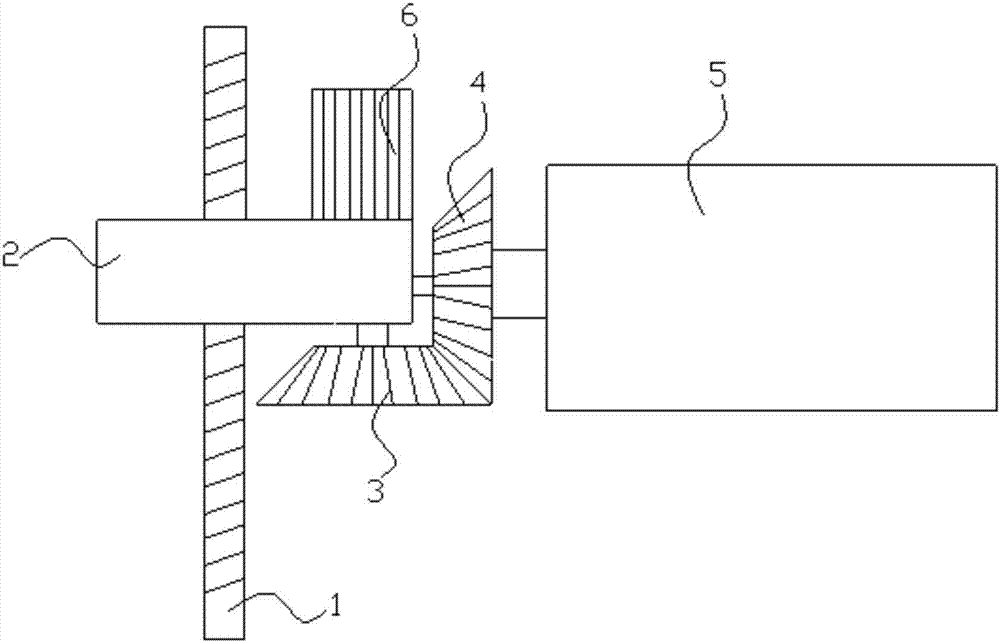

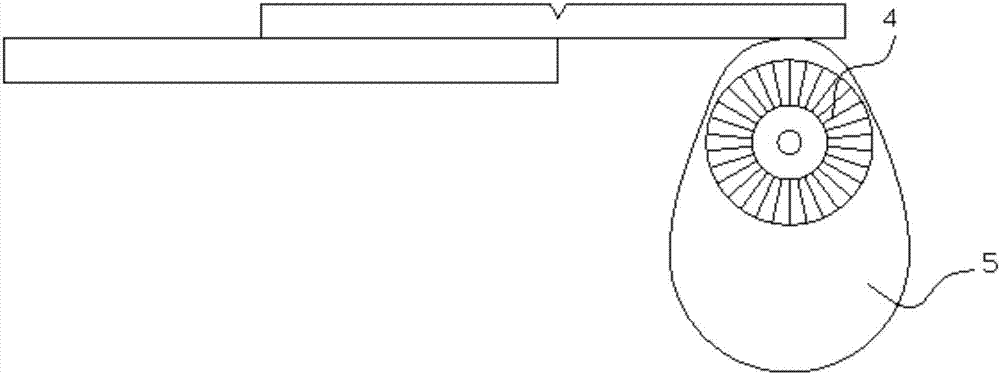

[0041] A, blanking, using laser cutting, the laser emitted from the laser is focused into a high-power-density laser beam through the optical path system, and the laser beam is irradiated on the surface of the workpiece to make the workpiece reach the melting point or boiling point, and at the same time it is coaxial with the beam The high-pressure gas blows away the molten or vaporized metal, and with the movement of the relative position of the beam and the workpiece, the material finally forms a slit, so as to achieve the purpose of cutting. no damage;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com