Sand blasting control system

A control system, sandblasting technology, applied to used abrasive treatment devices, manufacturing tools, abrasives, etc. problems, to reduce labor intensity, reduce personal injury, and achieve the effect of remote control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

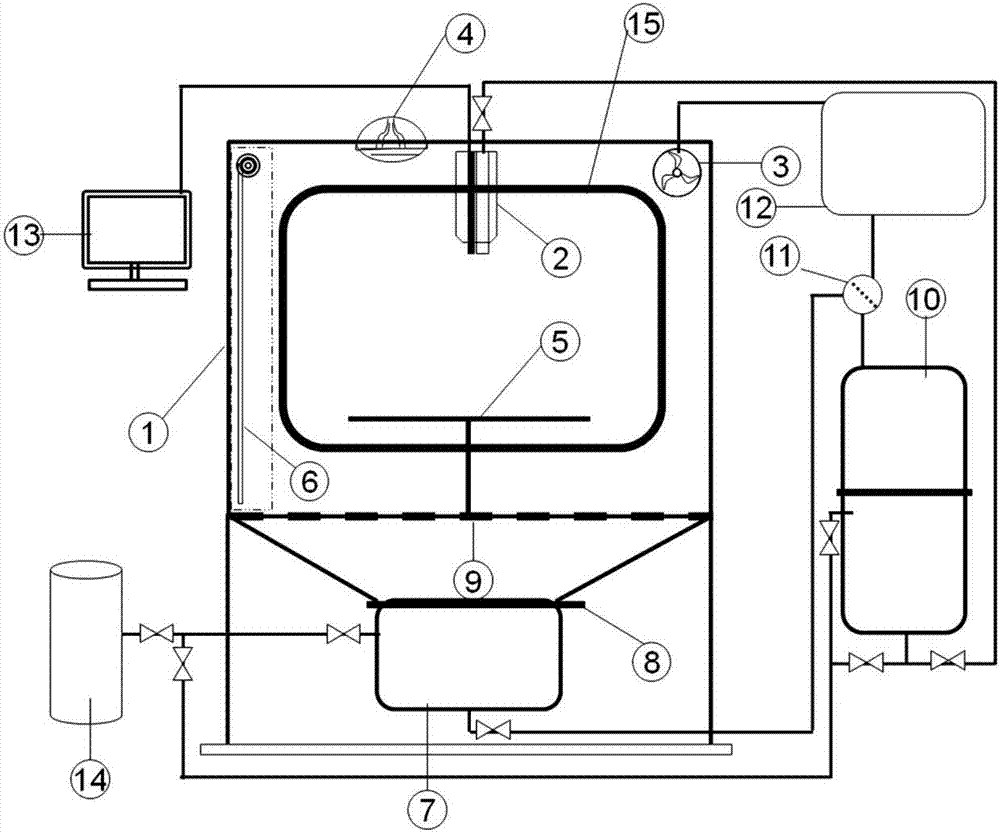

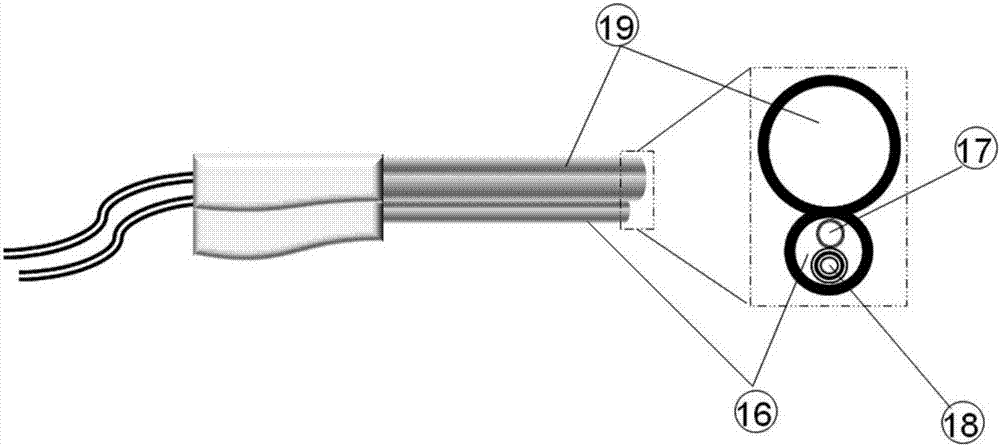

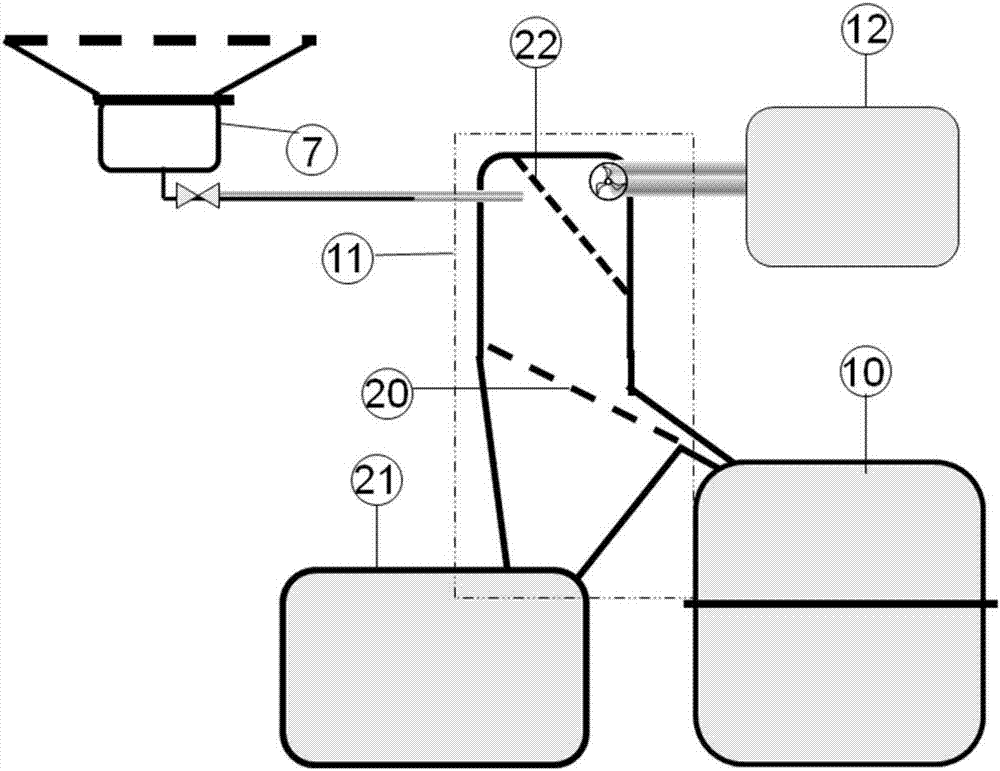

[0091] The sandblasting control system prepared according to the present invention comprises: a sandblasting room; windows are provided on the four side walls and the top of the room; transparent plastic soft curtains are provided inside the windows. There is a grid floor at the bottom of the sandblasting room; a movable workpiece carrying device is arranged on the grid floor in the sandblasting room, and the top of the sandblasting room is directly facing the workpiece carrying device, and the sand shot for blasting the workpiece is installed Spray head; the video recording device for sandblasting the surface of the workpiece is integrated on the sand blasting nozzle; Lighting unit and camera outside. The remote monitoring device is connected with the video recording device. The top of the blast booth is equipped with lighting and ventilation openings. The shot recovery device is installed at the lower part of the grid floor; the outlet of the conical collector is connected...

Embodiment 2

[0093] Using the device in Example 1, the sand shot is sprayed out through the sand shot nozzle, and the details of the surface of the workpiece are photographed by the video recording device, and transmitted to the remote monitoring equipment, so that the personnel can monitor the sandblasting effect of the details outside the box; through the movable workpiece While fixing the workpiece, the carrying device changes the position and posture of the workpiece through rotation, lifting and other actions, thereby adjusting the sandblasting effect. The light in the box can be guaranteed through the lighting equipment, and it is convenient to observe the operation situation from the outside; the anti-sand shot rebound device can buffer and offset the splashing kinetic energy of the sand shot, reducing the damage to the window, lighting equipment, box body and other equipment in the box. The scattered sand shot passes through the conical collector, and the sand shot is collected by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com