Chemical and blended fabric anti-static finishing production system

A chemical fiber fabric and production system technology, applied in the textile field, can solve the problems of lack of antistatic agent and unevenness of wrinkled fiber fabric, and achieve the effects of ensuring dyeing uniformity, improving softness and hand feeling, and improving spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The embodiments are described below with reference to the accompanying drawings. The embodiments shown below do not limit the invention content described in the claims. required for the solution.

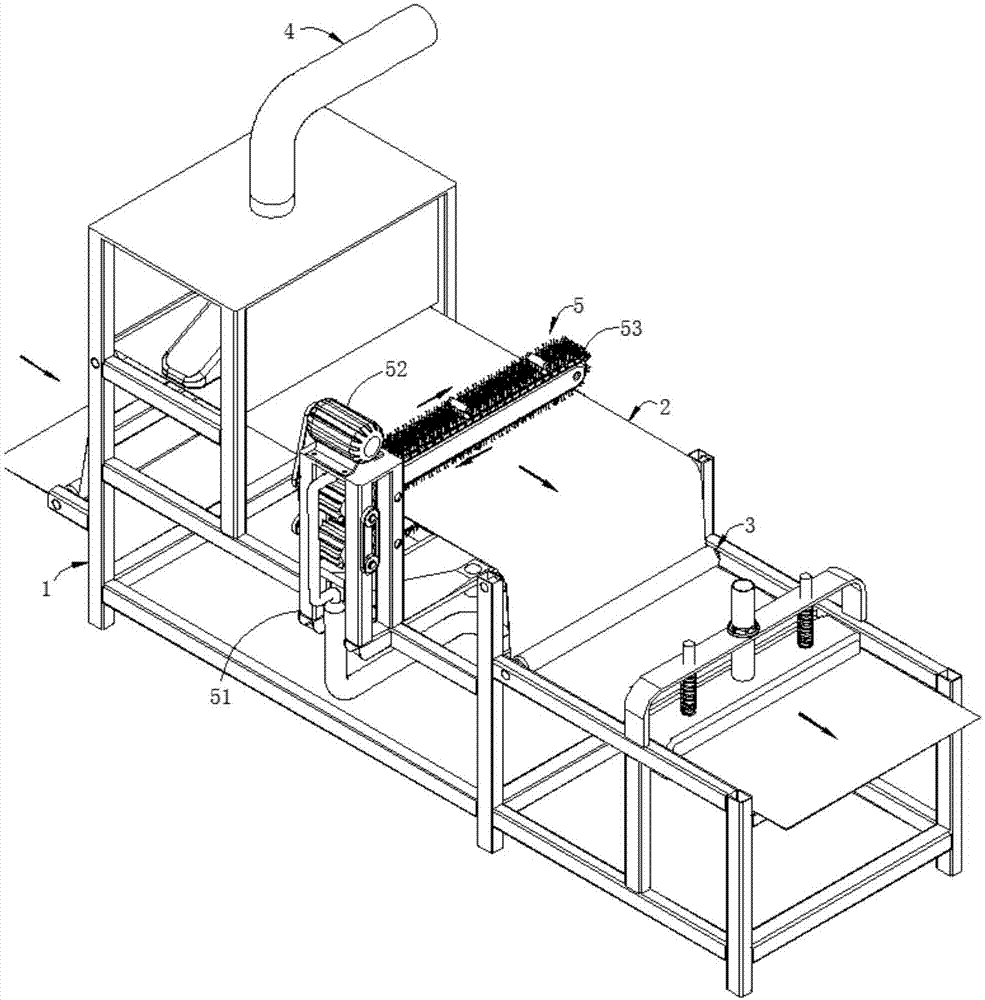

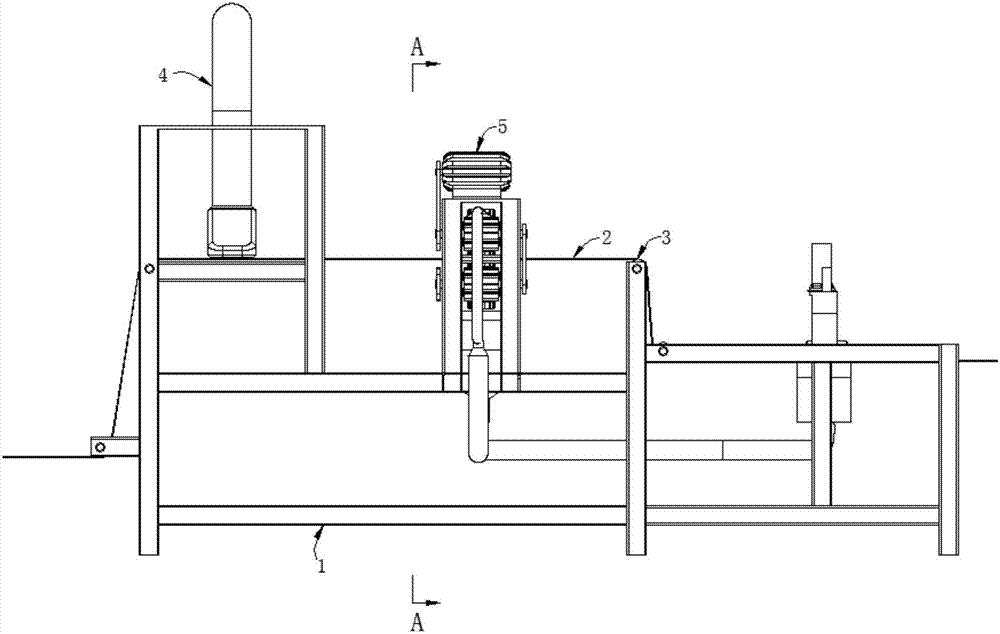

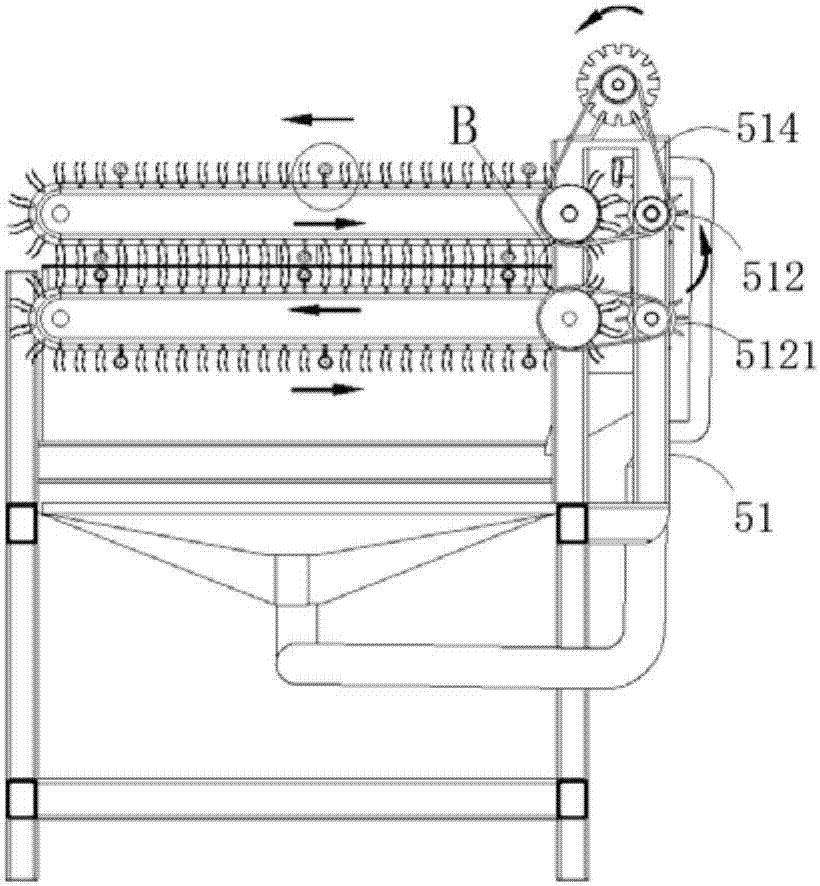

[0035] Such as figure 1 , 2 As shown, a chemical fiber fabric antistatic finishing production system includes a frame 1, a fiber fabric 2, a cloth guide roller 3 and a spraying mechanism 4 arranged at one end of the frame 1, and is characterized in that it also includes a The auxiliary mechanism 5 on one side of the spraying mechanism 4, the auxiliary mechanism 5 includes a support base 51 arranged on one side of the frame 1, and a drive assembly 52 fixedly installed on the top of the support base 51 is connected to the drive assembly 52 And be installed on one side of support seat 51 and be the smear mechanism 53 that synchronous operation is set up and down, described smear mechanism 53 is distributed in the upper and lower sides of fiber fabric 2 and is arranged in conta...

Embodiment 2

[0045] Such as Figure 9 , 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that it also includes a shaping and fixing mechanism 6 arranged on the lower section of the auxiliary mechanism 5 along the fiber fabric 2 and fixedly installed on the frame 1. 6 includes an adjustment support 61 fixedly installed on the frame 1 across the fiber fabric 2, an ironing assembly 62 arranged on the upper surface of the fiber fabric 2 through the adjustment support 61, and an ironing assembly 62 installed on one side of the ironing assembly 62 and connected to the fiber fabric. The flattening spring piece 63 that is in contact with the fabric 2, the shaping table 64 that is fixedly installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com