Liquid ammonia vaporizer and working method thereof

A vaporizer and liquid ammonia technology, which is applied in the field of liquid ammonia vaporization, can solve the problems of large equipment volume, poor liquid ammonia vaporization effect, and low safety, and achieve the effects of improving the boiling heat transfer coefficient, preventing frosting, and expanding the vaporization space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

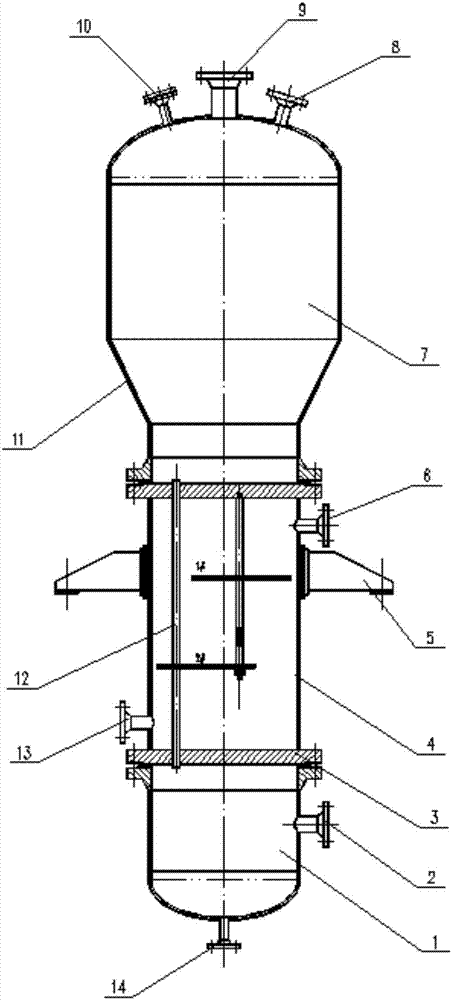

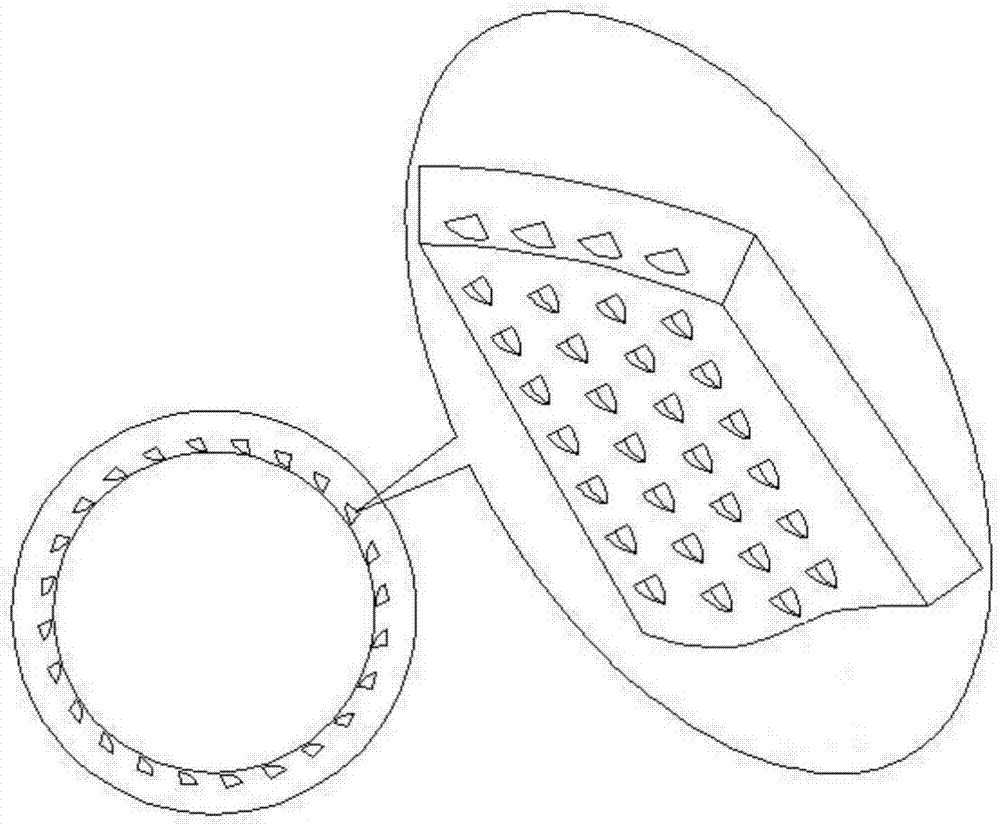

[0023] Such as figure 1 As shown, the ammonia vaporizer of the present invention includes a tube box 1, a heat exchange section 4 and a vaporization section 7 arranged sequentially from bottom to top; the bottom of the tube box 1 is provided with a vent 14, and the middle part is provided with a liquid ammonia inlet 2 ; The heat exchange section 4 is composed of a tube sheet 3, a heat exchange tube 12 and a shell-side cylinder, and the heat exchange section 4 is separated from the vaporization section 7 and the tube box 1 by upper and lower tube sheets 3 respectively, and the heat exchange tube 12 is vertically arranged in the shell-side cylinder of the heat exchange section 4, its upper end passes through the upper tube sheet 3 to communicate with the vaporization section 4, and its lower end passes through the lower tube sheet 3 to communicate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com