Testing method for water vapor penetration rate of thin film

A water vapor transmission rate and testing method technology, which is applied in the direction of permeability/surface area analysis, measuring devices, electrical components, etc., can solve the problems of many experimental parameters, expensive testing costs, relatively harsh equipment and laboratory conditions, etc., to achieve high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

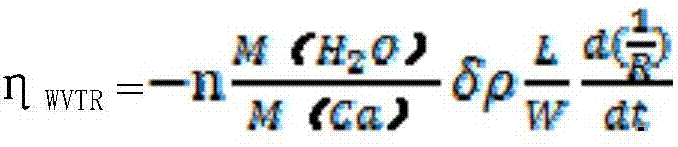

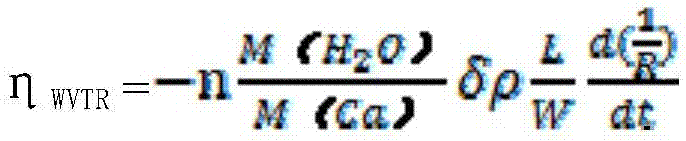

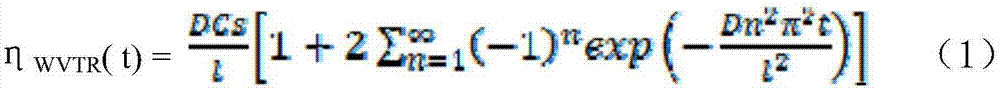

[0023] The method for testing the water vapor transmission rate of a film according to an embodiment of the present invention comprises the following steps:

[0024] S1. Evaporating a calcium thin film layer on the substrate.

[0025] Wherein, vacuum evaporation equipment is used to evaporate a calcium thin film layer on the substrate. In this embodiment, the thickness of the calcium film layer is 20-1000 nm, preferably 200 nm. The substrate is preferably a glass substrate.

[0026] S2. Under a protective gas, an encapsulation thin film layer is deposited on the substrate by atomic layer deposition, and the encapsulation thin film layer covers the calcium thin film layer to obtain a thin film device to be tested.

[0027] The thin film device to be tested has a three-layer structure, which is a substrate, a calcium thin film layer and an encapsulation thin film layer.

[0028] In this embodiment, the protective gas is nitrogen. Under the protection of nitrogen, the substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com