High-precision dissolved oxygen sensor based on fluorescent method

A dissolved oxygen sensor, high-precision technology, applied in the field of sensors, can solve problems such as real-time online detection, long detection time, secondary pollution, etc., to achieve long-term unattended remote monitoring, simple operation, and pollution-free effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

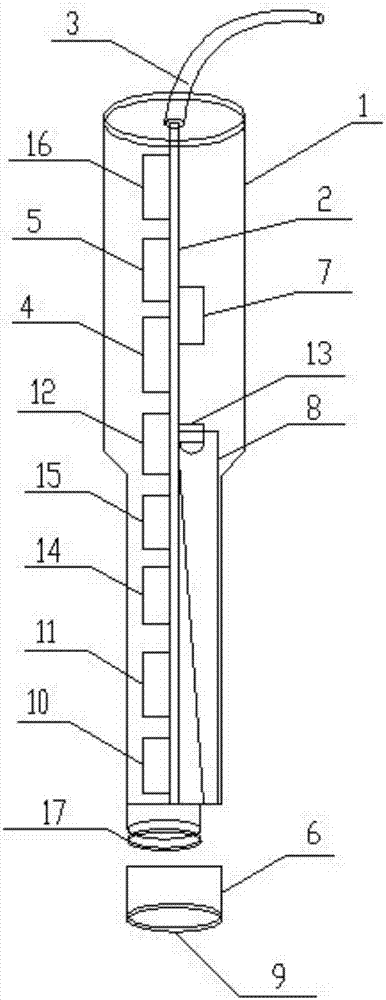

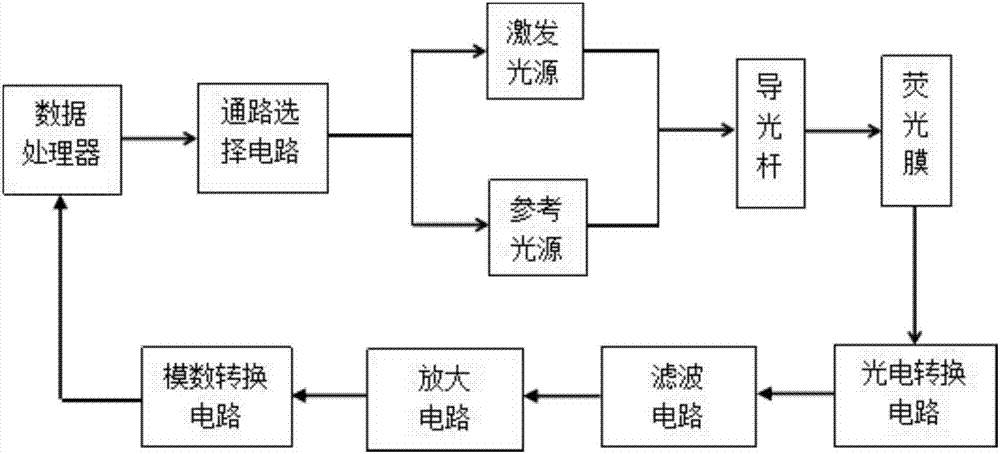

[0022] Such as figure 1 and 2 As shown, the high-precision dissolved oxygen sensor based on the fluorescence method provided in this embodiment includes a housing 1 and a circuit board 2 installed in the housing 1. The circuit board 2 is connected to the power supply through a cable 3; the circuit board 2 includes the conversion result for real-time reading of the analog-to-digital conversion circuit, and calculates the phase according to the conversion result and reference phase by phase and reference phase get phase difference The final solution to the dissolved oxygen concentration C do A data processor 4, a reference light source for emitting reference light, an excitation light source for exciting fluorescence, a communication circuit 5 for communicating with the third device, and a probe connected to the data processor 3 for two-way communication; the front end of the probe is fastened with a probe Cover 6.

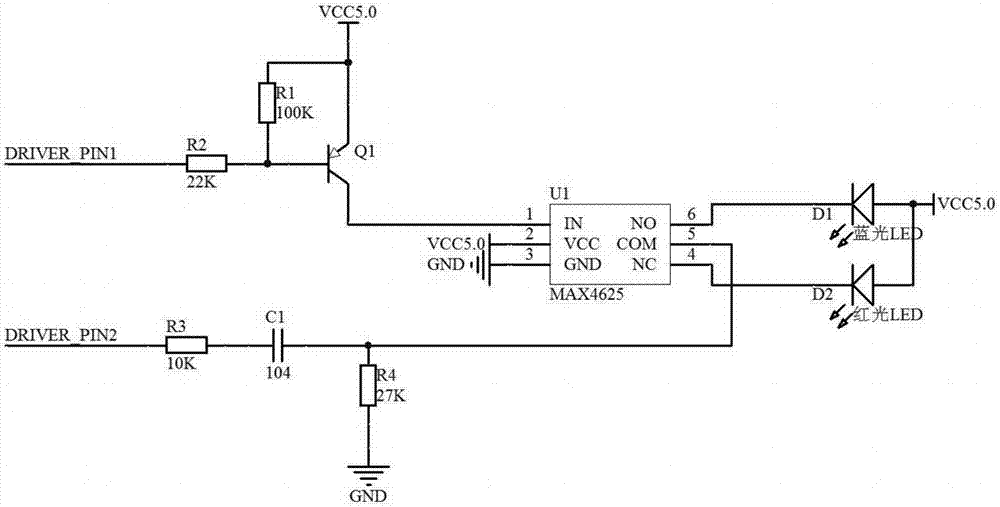

[0023] Wherein the signal output terminal of the d...

Embodiment 2

[0045] The dissolved oxygen sensor provided in this embodiment is basically the same in structure and principle as the dissolved oxygen sensor provided in Embodiment 1, the difference is that it also includes a temperature compensation circuit connected to the signal input end of the data processor; the temperature The compensation circuit can automatically compensate the dissolved oxygen value measured in the current environment to the dissolved oxygen value corresponding to 25°C and output the compensated dissolved oxygen value to the data processor.

[0046] The temperature compensation circuit includes a PT100 temperature probe, a bridge signal processing circuit and a signal amplification circuit. The circuit schematic diagram is as follows: Figure 6 Shown; including PT100 temperature probe interface for connecting PT100 temperature probe, resistors R25~R31, capacitors C18~C19 and operational amplifier TLV2780. The TC+ terminal of the PT100 temperature probe interface is...

Embodiment 3

[0050] In this embodiment, an optical filter 17 is added on the basis of the technical solutions of the first to second embodiments, and the optical filter 17 is arranged between the fluorescent film 9 and the photoelectric conversion circuit 10; it is used to filter out stray light. After the fluorescent film receives the light emitted by the light source (reference light source, excitation light source), it passes through the filter and then enters the photoelectric conversion circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com