Adaptive sound time calculation method in ultrasonic thickness measurement

A calculation method and self-adaptive technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measurement devices, radio wave measurement systems, etc., can solve the problems of difficulty in ensuring calculation accuracy and stability, and achieve improved calculation accuracy, accuracy and reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with specific embodiments and related drawings.

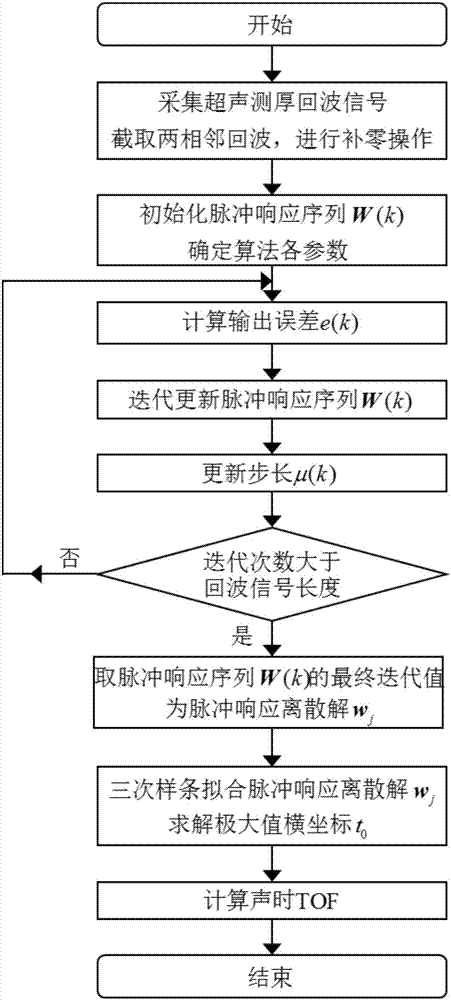

[0039] The embodiment of the present invention adopts such as figure 1 The shown calculation flow chart of ultrasonic thickness measurement uses an ultrasonic probe with a center frequency of 10MHz for ultrasonic transmission and reception, and the acquisition frequency of ultrasonic signals is 2.5GHz. Ultrasonic thickness measurement was carried out on 6 aluminum alloy specimens of different thicknesses. The actual thickness of the specimens was measured by a coordinate machine as shown in Table 1.

[0040] Table 1 CMM measurement results of the thickness of each specimen

[0041]

[0042] The present invention will be further described in detail through the sound time measurement method of a specimen with a thickness of 6 mm.

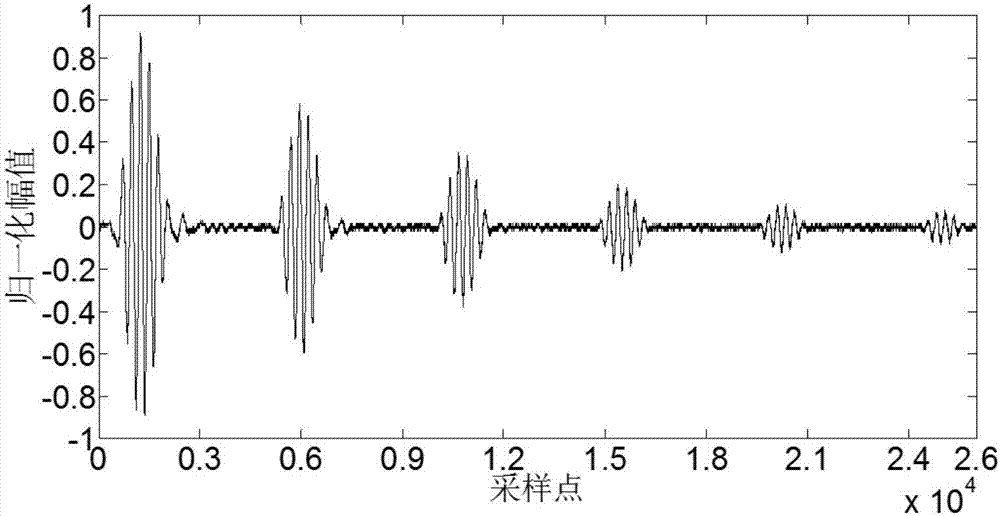

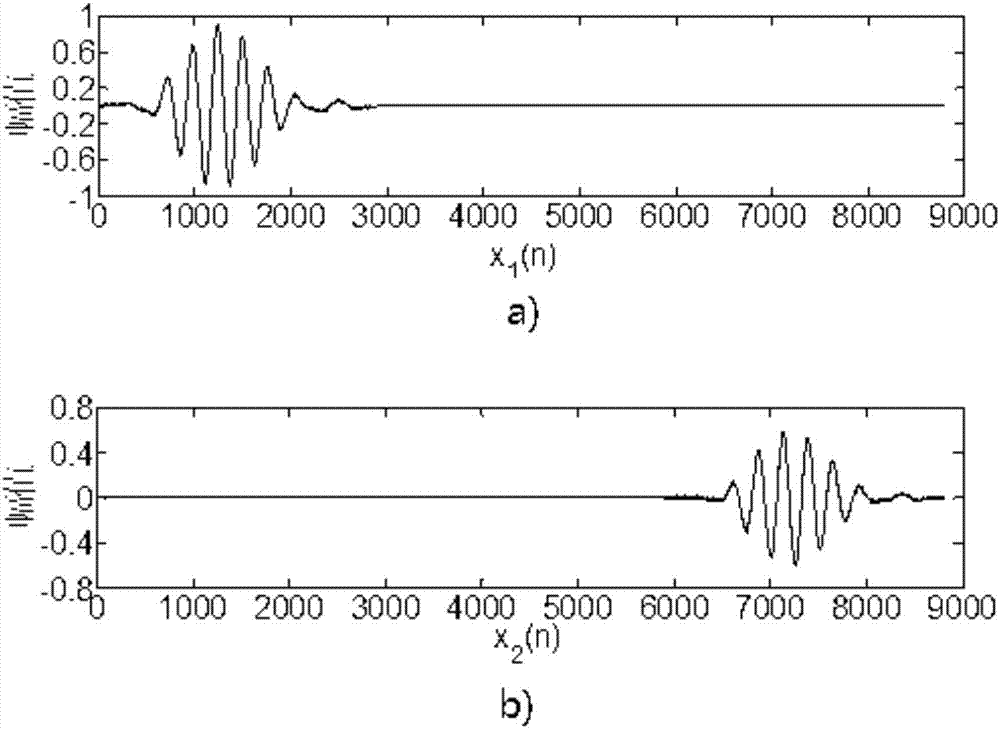

[0043] The first step is acquisition and preprocessing of ultrasonic echo signals. The acquired ultrasonic pulse echo signal is li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com