Fixed 3D glue dispensing machine

A dispensing machine and fixed technology, which is applied in the field of dispensing machines, can solve the problems of low manual dispensing efficiency, affecting product quality, and rising labor costs, so as to improve dispensing efficiency, reduce dispensing time, and reduce labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

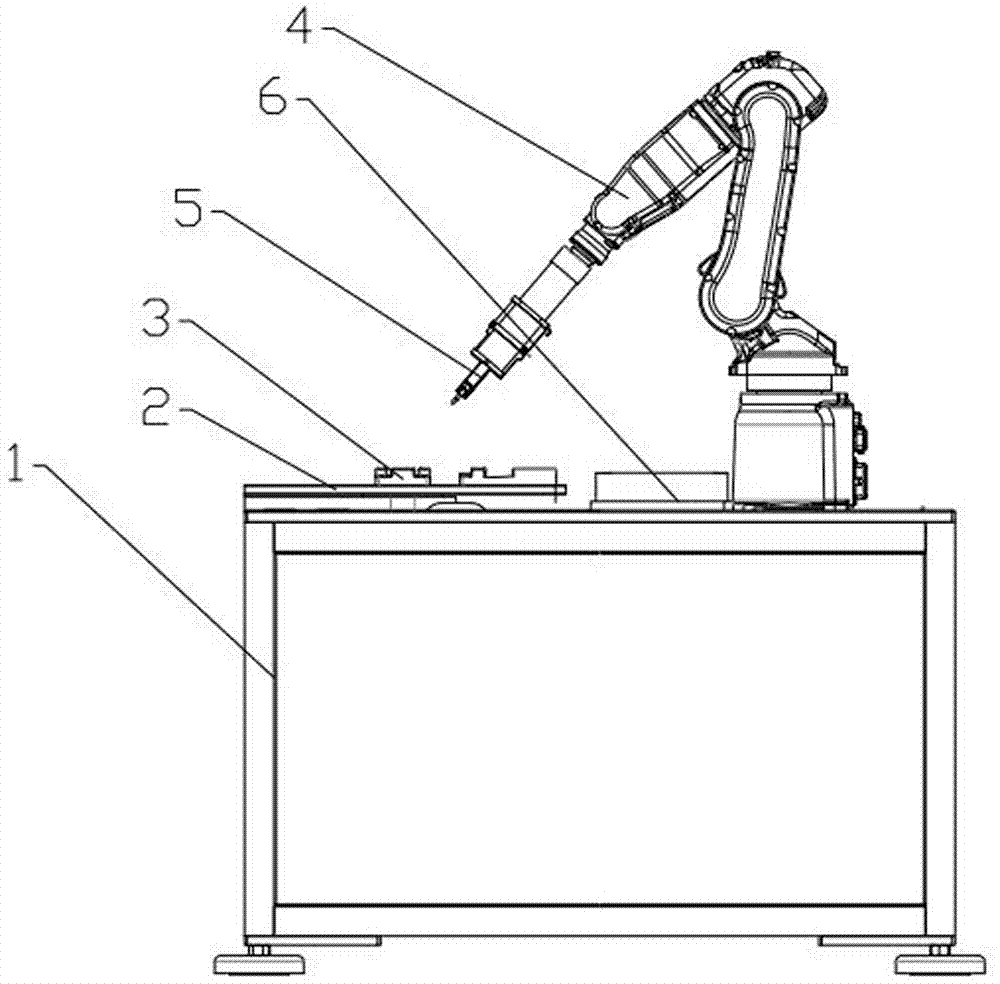

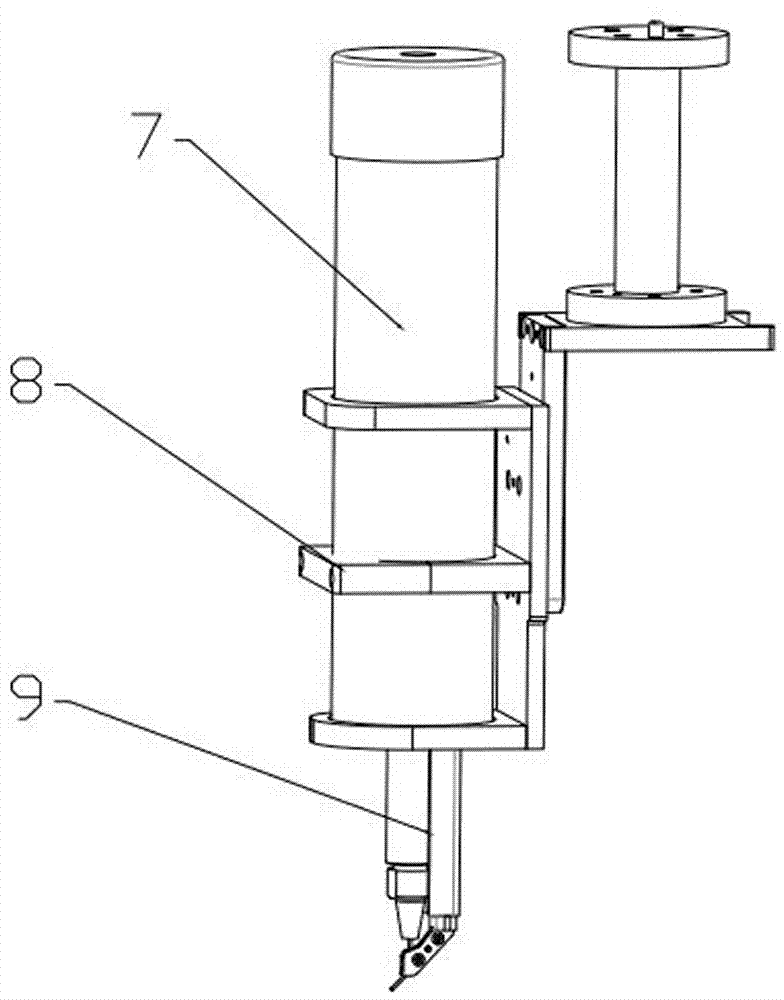

[0029] see figure 1 , a fixed 3D glue dispenser, including a frame, a workbench, a fixed fixture, a positioning mechanism, a six-axis manipulator, a glue dispensing mechanism and a control system.

[0030] The frame is used to assemble the various parts of the mechanism together.

[0031] The worktable is arranged on the frame and is a platform for dispensing products. Preferably, the worktable is slidably arranged on the frame, and the specific structure of the worktable being slidably arranged on the frame is not particularly limited in the present invention, which can be known by those skilled in the art based on common knowledge and prior art. For example, the worktable can be set on the frame by means of rotation or translation.

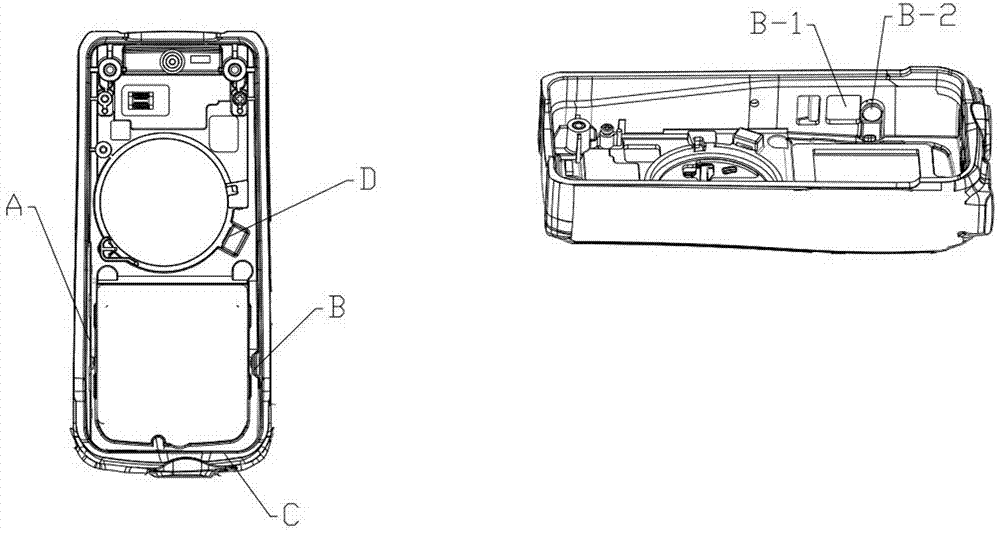

[0032] The fixing jig is arranged on the working table and is used for fixing the product to be dispensed. Due to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com