Pressure-adjustable spring compression soldering welding device and method

A spring pressing and welding device technology, applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve problems such as unstable welding quality, achieve the effect of simple structure, continuously adjustable pressure, and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

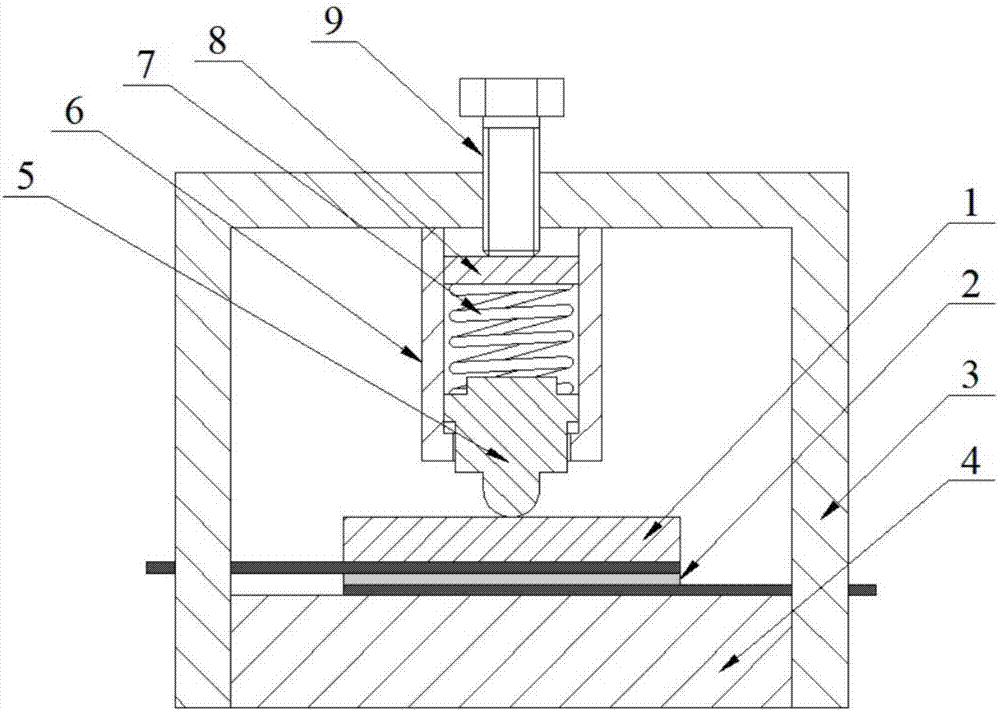

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] Such as figure 1 As shown, the pressure-adjustable spring compression soldering welding device described in this embodiment includes a heating plate 4, a joint pressing block 1, a connecting frame 3 and a spring mechanism, and the spring mechanism includes a pressure head 5, a spring sleeve Barrel 6, spring 7, pressing plate 8 and force screw rod 9. The high-temperature superconducting tape joint 2 is two high-temperature superconducting tapes including a solder sheet placed between them. The used high-temperature superconducting strips and solders are cleaned with alcohol and acetone before use to avoid direct contact with the strips and solders with hands.

[0027] The installation process of the pressure-adjustable spring compression soldering welding device in this embodiment is as follows: first, the pressure head 5, the spring 7, and the pressing block 8 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com