Crawler type moving telescopic automatic stacking device and stacking method thereof

A mobile telescopic, crawler-type technology, applied in the direction of conveyor control device, loading/unloading, transportation and packaging, etc., can solve the problems of narrow working surface, poor maneuverability, high design cost, etc., achieve strong flexibility and increase unloading capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

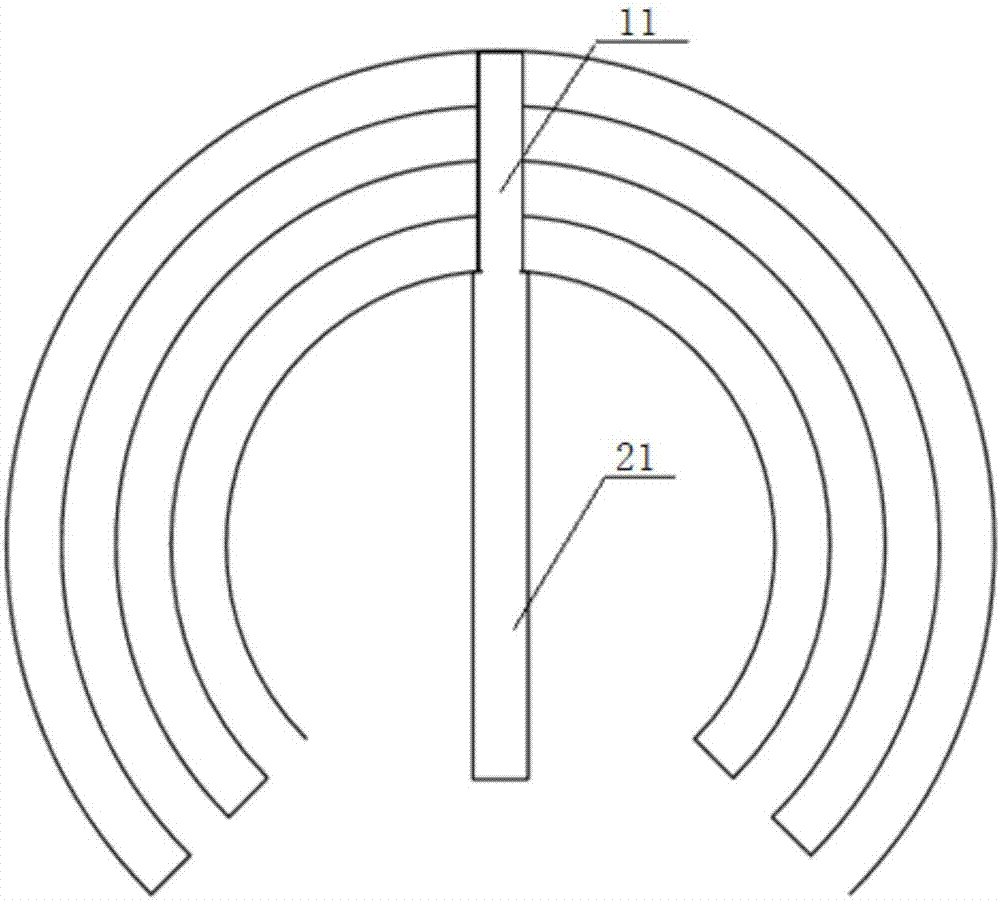

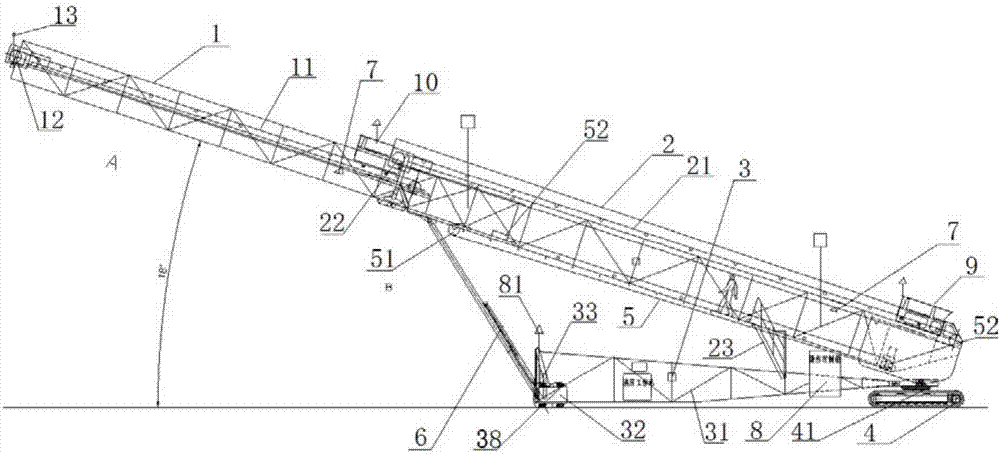

[0049] In this embodiment, a crawler-type mobile telescopic automatic stacking device, such as figure 2 As shown, the crawler-type mobile telescopic automatic stacking device includes an inner truss 1, an outer truss 2, a horizontal swing mechanism 3, a crawler-type moving mechanism 4, a radial telescopic mechanism 5 and a support mechanism 6; the inner truss 1 and the outer The vertical of the truss 2 is respectively fixedly connected with an inner conveyor belt 11 and an outer conveyor belt 21, the lengths are respectively 12m and 13m, and the width is 1m; The lower part of 21 expands and contracts vertically along the outer truss 2; the top of the support mechanism 6 is fixedly connected to the upper part of the outer truss 2; through the radial expansion mechanism 5, the inner conveyor belt 11 is extended outward according to the needs, which improves the transportation of materials. Conveying length and freedom of length adjustment. The crawler-type mobile mechanism 4 i...

Embodiment 2

[0059] The basic structure and steps of the crawler-type mobile telescopic automatic stacking device of this embodiment are the same as that of Embodiment 1. The difference and improvement are that the swing angle of the horizontal swing frame 34 is 45°, which can form a 90° fan ring. It is suitable for unloading and drying in areas with small working faces; the lengths of the inner conveyor belt 11 and the outer conveyor belt 21 are 15m and 16m respectively, and the width is 1.2m; each time the radial telescopic mechanism 5 extends the inner conveyor belt 11 by 5m , including the following steps:

[0060] Step 1: Start the horizontal swing mechanism 3: the horizontal swing frame 34 cooperates with the supporting mechanism 6 to drive the outer conveyor belt 21 to swing to the left with the slewing bearing or the traction support 41 as the center of the circle, and the vertical length of the outer conveyor belt 21 is a fan-shaped track to swing to the left until it is horizontal...

Embodiment 3

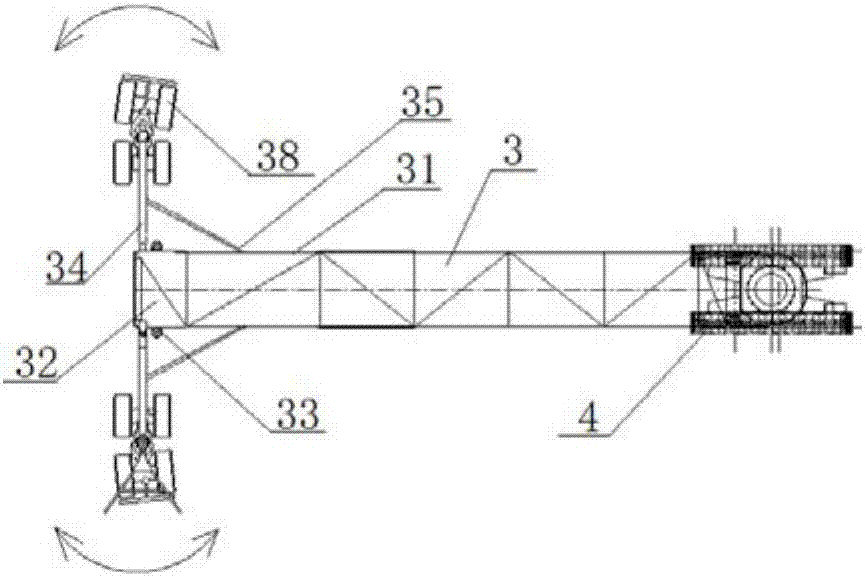

[0070] The basic structure and steps of the crawler-type mobile telescopic automatic stacking device of this embodiment are the same as that of Embodiment 2, the difference and improvement are that the horizontal swing mechanism 3 also includes a wheel adjustment mechanism and 2 diagonal stays 35, and the bottom truss 31, the two ends of each cable-stayed strut 35 are detachably and fixedly connected with the bottom truss 31 and the horizontal swing frame 34 respectively, and are used for stabilizing the swing of the horizontal swing frame 34 to prevent its random swing from affecting the unloading process. stability. Such as Figure 4 As shown, the runner adjustment mechanism includes a top-down hydraulic cylinder 33 and a horizontal swing shaft 36, and the two horizontal swing frames 34 are connected in a rotational manner through the horizontal swing shaft 36 and the bottom truss 31 respectively; the top-down hydraulic cylinder 33 There are two, which are respectively fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com