Infrared ray camouflage coating, camouflage production method utilizing same and camouflage overcloth

A stealth paint and infrared technology, applied in the field of infrared stealth paint and stealth clothing, can solve the problems of lack of stealth ability and inability to achieve infrared stealth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

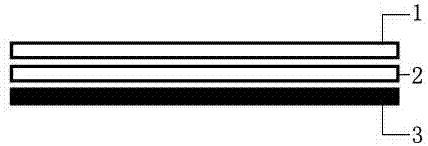

Image

Examples

Embodiment 1

[0022] An infrared stealth paint, which includes southern woodland type paint, northern woodland type paint, grassland type paint, and desert type paint; southern woodland type paint includes dark green DG0730 paint, emerald green EG1456 paint, loess YE2344 paint; northern woodland type paint includes dark green Green DG0730 paint, emerald green EG1456 paint, sandy soil SE2635 paint; grassland type paint includes dark green DG0730 paint, emerald green EG1456 paint, sandy soil SE2635 paint; desert type paint includes yellow green YG1247 paint, cinnamon BE1732 paint, sandy soil SE3948 paint; dark green DG0730 Contains the following ingredients: 26% chrome green, 16.8% macromolecule yellow, 0.5% near-infrared high-reflective black, 6.1% talcum powder, 1.5% matting agent, 36.8% acrylic resin, 12.4% isocyanate; yellow-green YG1247 contains the following ingredients: chromium Green 22.8%, medium chrome yellow 18.2%, sky blue 0.5%, titanium dioxide 2.3%, talcum powder 6.1%, matting ag...

Embodiment 2

[0024]An infrared stealth paint, which includes southern woodland type paint, northern woodland type paint, grassland type paint, and desert type paint; southern woodland type paint includes dark green DG0730 paint, emerald green EG1456 paint, loess YE2344 paint; northern woodland type paint includes dark green Green DG0730 paint, emerald green EG1456 paint, sandy soil SE2635 paint; grassland type paint includes dark green DG0730 paint, emerald green EG1456 paint, sandy soil SE2635 paint; desert type paint includes yellow green YG1247 paint, cinnamon BE1732 paint, sandy soil SE3948 paint; dark green DG0730 Contains the following ingredients: 24% chrome green, 14.8% macromolecule yellow, 0.3% near-infrared high-reflective black, 1.1% talc, 0.5% matting agent, 28.8% acrylic resin, 4.4% isocyanate; yellow-green YG1247 contains the following ingredients: chromium Green 20.8%, medium chrome yellow 16.2%, sky blue 0.3%, titanium dioxide 0.3%, talcum powder 1.1%, matting agent 0.5%, a...

Embodiment 3

[0026] An infrared stealth paint, which includes southern woodland type paint, northern woodland type paint, grassland type paint, and desert type paint; southern woodland type paint includes dark green DG0730 paint, emerald green EG1456 paint, loess YE2344 paint; northern woodland type paint includes dark green Green DG0730 paint, emerald green EG1456 paint, sandy soil SE2635 paint; grassland type paint includes dark green DG0730 paint, emerald green EG1456 paint, sandy soil SE2635 paint; desert type paint includes yellow green YG1247 paint, cinnamon BE1732 paint, sandy soil SE3948 paint; dark green DG0730 Contains the following ingredients: 28% chrome green, 18.8% macromolecule yellow, 2.5% near-infrared high-reflective black, 11.1% talcum powder, 6.5% matting agent, 44.8% acrylic resin, 20.4% isocyanate; yellow-green YG1247 contains the following ingredients: chromium Green 24.8%, medium chrome yellow 20.2%, sky blue 2.5%, titanium dioxide 4.3%, talcum powder 11.1%, matting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com