Infrared stealth material with multi-layer structure

A technology of stealth material and multi-layer structure, applied in the field of flexible materials, can solve the problems of complex preparation process, high cost, environmental pollution, etc., and achieve the effects of simple preparation process, low overall cost and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

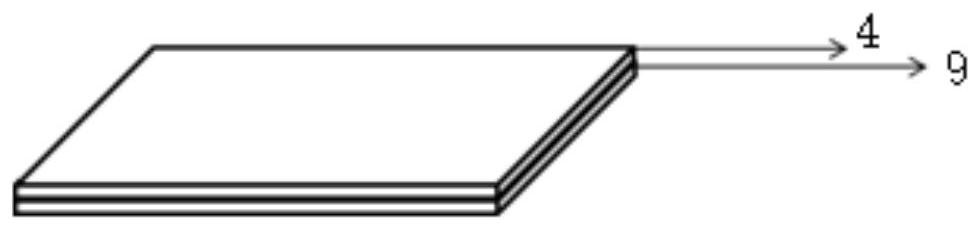

[0031] combined with figure 1 , a kind of infrared stealth material with an auxiliary layer added on one side, which is the core layer, namely the hydrogel layer 4) and the heat insulation layer 9 in sequence.

[0032] Wherein: the hydrogel layer 4 is polyacrylamide hydrogel containing calcium chloride electrolyte. The heat insulating layer 9 is an air bubble cushion coated with a heat reflective coating (or heat reflective paint).

[0033] During the preparation, the hydrogel was flatly spread on the air bubble pad with a thickness of 1 mm and the thickness of the air bubble pad was 2 mm. The layers are secured with seams.

[0034] To test its infrared stealth performance, the temperature of the hot stage is controlled at 35°C, the material is covered on the hot stage, and the infrared detector is used to detect it every ten minutes to achieve complete infrared stealth for one hour.

Embodiment 2

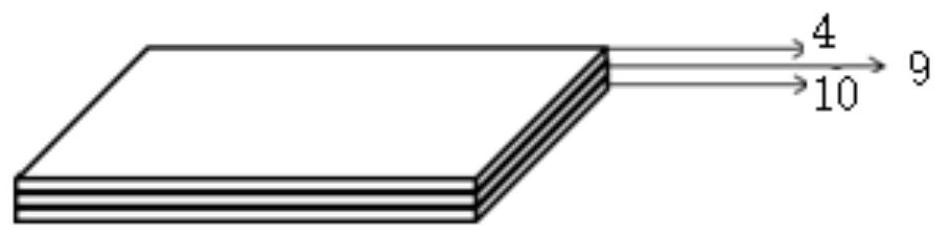

[0036] combined with figure 2 , an infrared stealth material with an auxiliary layer added on one side, comprising a hydrogel layer 4, a heat insulating layer 9, and a heat conducting layer 10 from top to bottom.

[0037] Wherein the hydrogel layer 1 is a starch hydrogel containing calcium chloride electrolyte; the heat insulating layer 9 is a heat insulating air bubble pad; the heat conducting layer 10 is selected to have good thermal conductivity and can adhere to the heat conducting carbon on the surface of the material black powder.

[0038] During preparation, spread the hydrogel on the thermal insulation air cushion with a thickness of 2 mm, and the thermal insulation air cushion with a thickness of 0.5 mm, and spray a layer of thermally conductive graphite powder on the hydrogel with a thickness of 0.1 mm. The layers are secured with sutures.

[0039] Cover the bare arm with the material, and use an infrared detector to detect it every ten minutes. The results show t...

Embodiment 3

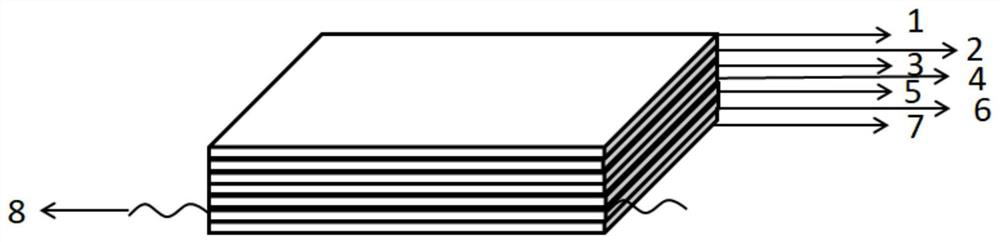

[0042] combined with image 3 ,, an infrared stealth material with a double-layer double-sided structure, from top to bottom is the environment adaptive layer 1, the first heat insulation layer 2, the first heat conduction layer 3, the hydrogel layer 4, and the second heat insulation layer 5. The second heat-conducting layer 6 , the air-permeable fabric layer 7 , and the heat-conducting fixing device 8 .

[0043] Wherein the environmental adaptation layer 1 adopts high-strength fabric coated with high-density polyethylene grafted maleic anhydride coating film and camouflage ink composite layer; the first heat insulation layer 2 and the second heat insulation layer 5 adopt thermal insulation Paper; the first heat conduction layer 3 and the second heat conduction layer 6 adopt heat conduction graphene; the hydrogel layer 4 adopts starch hydrogel containing magnesium nitrate electrolyte and compounded silicon carbide fiber; the breathable fabric layer 7 Soft breathable cotton fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com