Infrared and radar compatible stealth window glass with sound insulation and heat insulation functions

A technology of window glass and outer glass, applied in the field of wave absorbing materials, can solve the problems of inability to achieve sound insulation and heat insulation, and inability to meet higher requirements, and achieve the effects of reducing the probability of detection, efficient reflection, and preventing internal and external heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

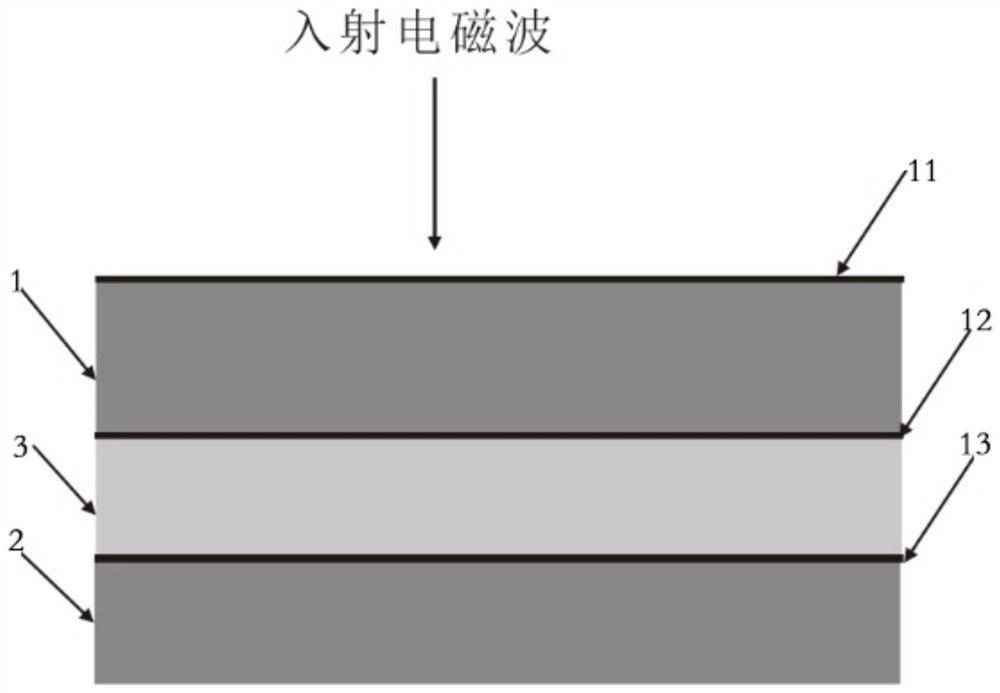

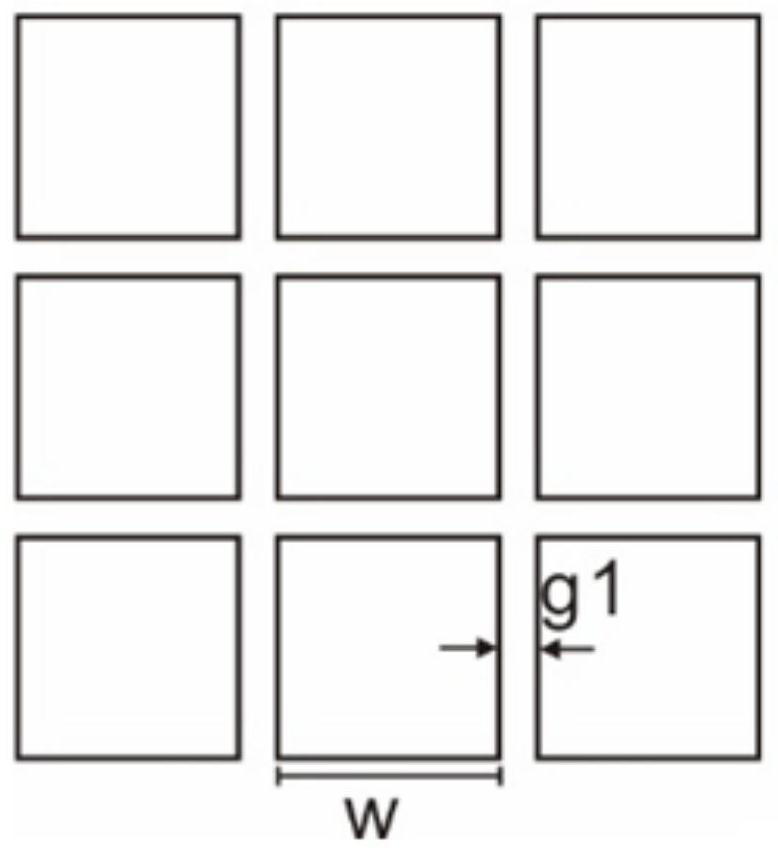

[0036] In the present invention, the microwave frequency selective surface structure array 11 is a graphic structure array formed by depositing the first transparent conductive film material on the outer surface of the outer glass 1. The graphic structure is a periodic array of a specific shape, and the shape can be square, circular, Regular or irregular structures such as rectangles, the structure array has selective permeability to microwaves, and can make the 5-20GHz frequency band have high transmittance. According to an embodiment of the present invention, the period of the graphic structure array is 0.5 mm, and the graphic structure is a square. The first transparent conductive film material is indium tin oxide or zinc aluminum oxide, its square resistance is 8-15Ω / sq, and its thickness is 200-250nm. The conductive film with this parameter has high conductivity, so as to ensure the surface of the window Infrared emissivity is less than 0.25.

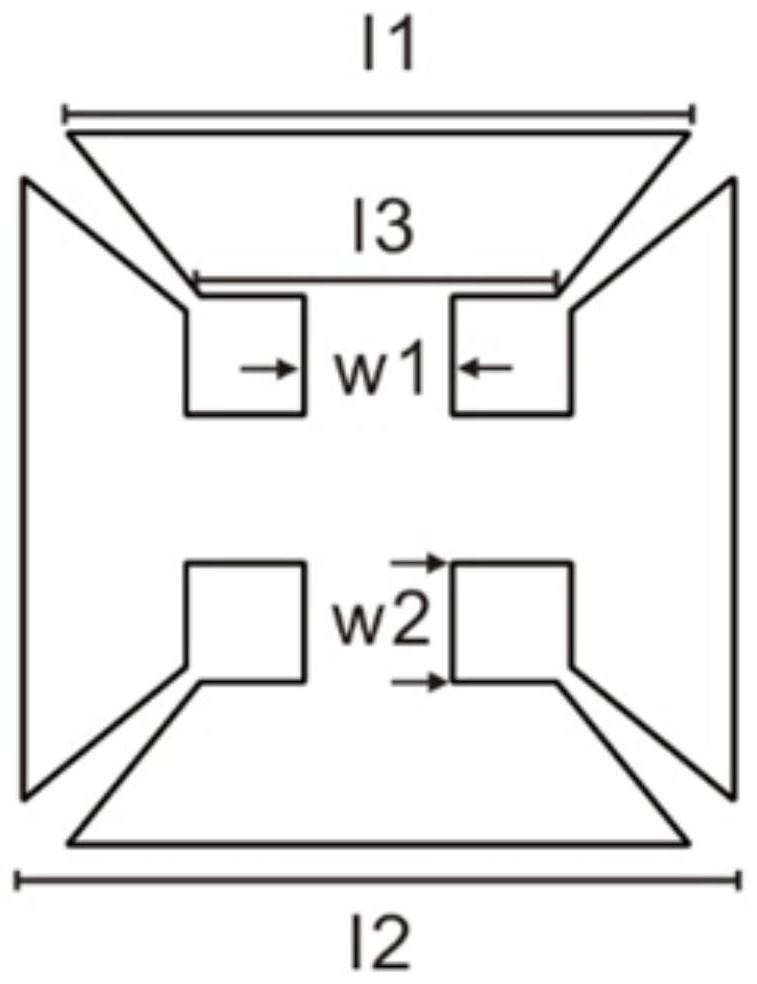

[0037] The microwave reson...

Embodiment 1

[0047] combine figure 1 As shown, the outer glass 1 and the inner glass 2 in this embodiment are made of quartz glass, both of which have a dielectric constant of 3.75. Wherein the thickness of the outer glass 1 is 3 mm, the thickness of the inner glass 2 is 1.5 mm, and the thickness of the vacuum layer is 2.7 mm. The microwave frequency selective surface structure array 11 and the microwave resonant structure array are prepared on the outer surface and the inner surface of the outer glass 1 by photolithography process and wet etching process respectively. like Figure 6 As shown, the visible light average transmittance of the window ratio in this embodiment is higher than 60%.

[0048] In this embodiment, the configuration of the microwave frequency selective surface structure array is as follows figure 2 As shown, the structure is a square array. Wherein the structural parameters g1=0.1, w=0.45. This structural array can ensure that the microwave transmittance of 5-20G...

Embodiment 2

[0052] combine figure 1 As shown, the outer glass 1 and the inner glass 2 in this embodiment are made of organic glass, and the dielectric constants are both 2.45. The thickness of the outer glass 1 is 2.8 mm, the thickness of the inner glass 2 is 1.5 mm, and the thickness of the vacuum layer is 2.6 mm. The microwave frequency selective surface structure array 11 and the microwave resonant structure array are respectively prepared on the outer surface and the inner surface of the outer glass 1 by laser etching.

[0053] In this embodiment, the configuration of the microwave frequency selective surface structure array is as follows Figure 4 As shown, the structure is a regular hexagonal array. Wherein the structural parameters g2=0.008, d=0.2. This structural array can ensure that the microwave transmittance of 5-20GHZ is greater than 98%. Indium tin oxide (ITO) is selected as the material of the transparent film, its square resistance is 8Ω / sq, and the film thickness is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com