Multicolor gradient color digital yarn knitted fabric and preparing method thereof

A knitted fabric, a colorful technology, applied in the directions of knitting, weft knitting, yarn, etc., can solve the problems of inconvenient adjustment and control, complicated process adjustment, affecting yarn sliver, etc., to achieve a strong three-dimensional and fashion sense, Broad application prospects and unique style effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Specific process flow:

[0042] Yarn production: picking cotton→mixing→opening→rolling→carding→combing preparation→combing drawing→roving (three colors)→spun yarn (colorful gradient digital yarn);

[0043] Fabric production: colorful gradient digital yarn → doubling → rewinding → woven piece → sleeve → flat car → hand sewing → washing → drying → ironing → packaging → storage.

[0044] (1) Yarn design

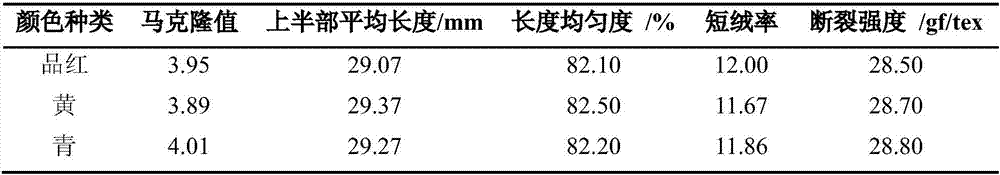

[0045] In order to make the developed product not only have good hand feeling, moisture absorption, softness and other wearable performance requirements, and rich gradient layers, but also have a fashionable, casual and generous appearance style, cotton fiber is used as raw material, and cyan, magenta and Cotton fibers in three colors of yellow are mixed and spun to highlight its style.

[0046] In terms of gradient effect presentation, gradient blending ratio changes are adopted, and the color rendering effect of blending at the fiber scale is optimized.

[0047] Duri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com