Outer protective cover of drying cylinder glue applicator

A technology of cylinder sizing machine and outer shield, which is applied in the field of papermaking machinery, can solve problems such as cumbersome maintenance procedures for sizing machines, inability to remove the sizing machine from the shield, and affect maintenance progress, etc., to achieve good promotion and use value, The effect of improving the efficiency of troubleshooting and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

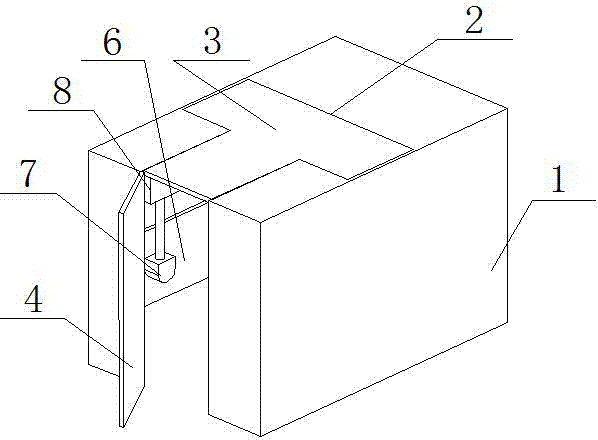

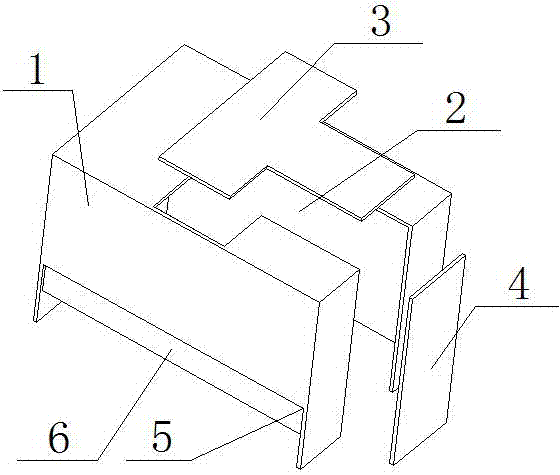

[0024] A kind of dryer sizing machine outer shield of the present invention comprises outer shield 1, and dryer sizing machine is arranged in outer shield 1; Outer shield 1 is the outer shield 1 of cuboid structure, and outer shield 1 There is a T-shaped opening groove Ⅰ2 on the top, and the T-shaped sealing plate 3 is movably arranged in the T-shaped opening groove Ⅰ2; an opening and closing door 4 is arranged at the center of one side of the outer shield 1, and the top of the opening and closing door 4 is connected to the T The font-shaped opening groove I2 is connected correspondingly; the bottom of one side of the outer shield 1 is provided with an opening groove II5, and the opening groove II5 is provided with a lifting cover wall 6 with a cuboid structure; the inner wall of the lifting cover wall 6 is symmetrically provided with 2 Two cylinder connectors 7, two cylinders 8 are symmetrically arranged on the top of the inner wall of the outer shield 1 side, and the telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com