Control system for high exhaust vent valve of megawatts unit turbine

A control system, a technology of millions of units, applied in valve details, valve devices, mechanical equipment, etc., can solve the problems of loose air pipe joints, solenoid valve coil burnout, and high temperature, so as to reduce the probability of burnout and reduce failures. , The effect of reliable and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with embodiment.

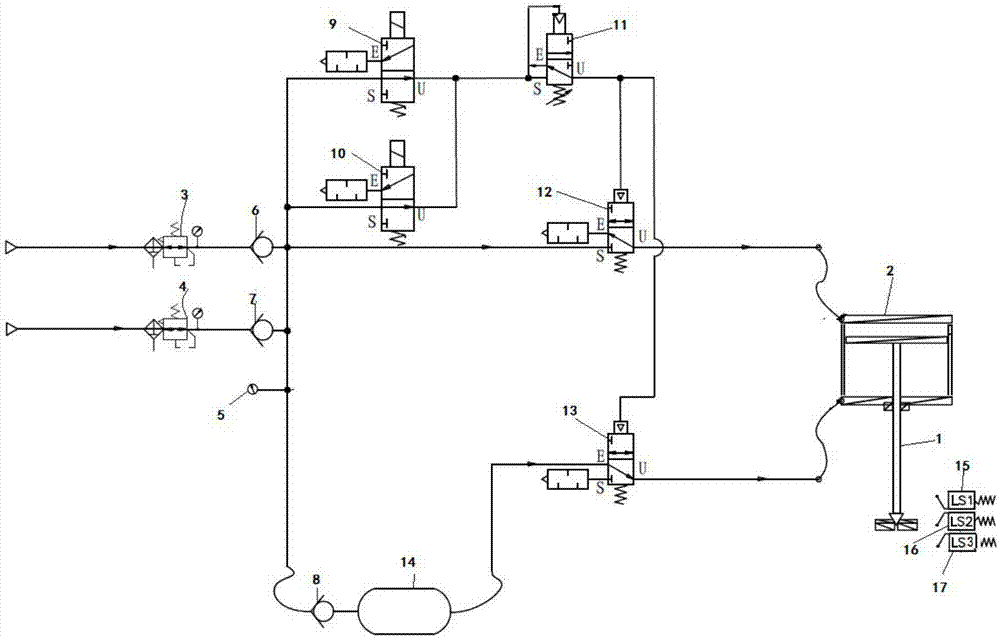

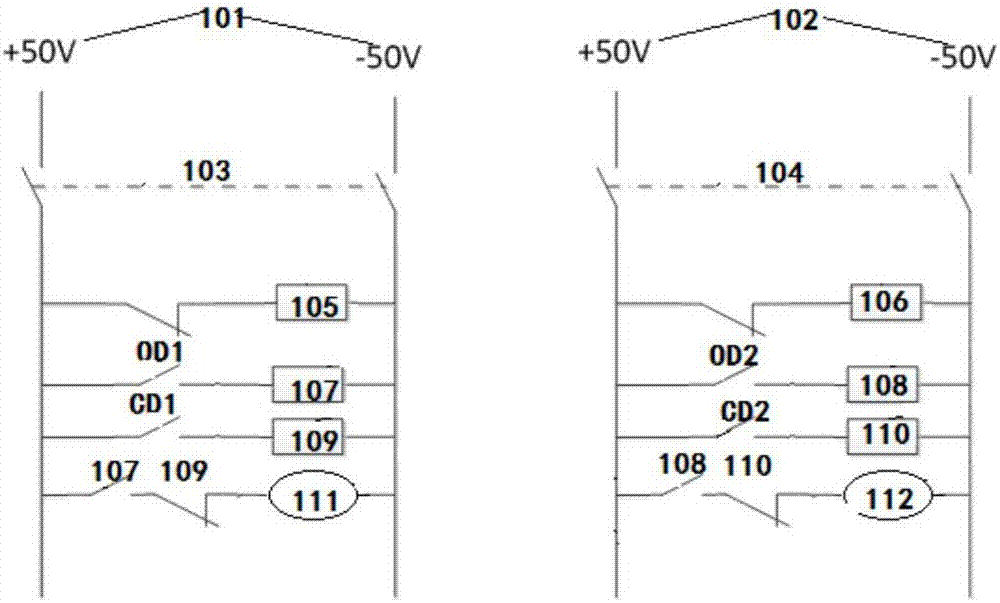

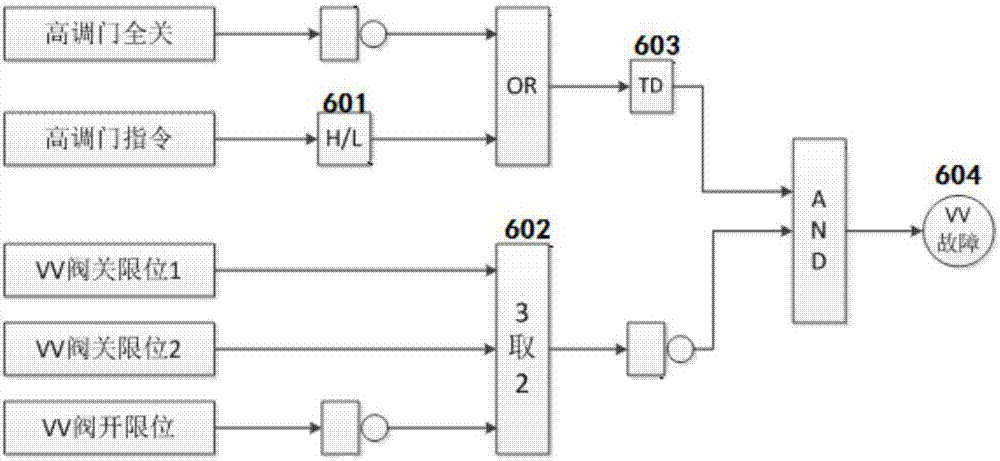

[0032] The embodiment of the high exhaust ventilation valve control system of a steam turbine with a million units of the present invention includes a pneumatic pipeline, a double-acting cylinder 2, two control circuits and a high exhaust ventilation valve fault diagnosis device.

[0033] Such as figure 1 Schematic diagram of the assembly of the pneumatic lines and double-acting cylinder shown. The telescopic rod 1 of the double-acting cylinder 2 is connected to the spool of the high-discharge ventilation valve, and the closing and opening of the high-discharge ventilation valve is completed by extending and retracting the telescopic rod. The pneumatic pipeline includes two independent and identically configured intake pipelines, a first execution pipeline, a second execution pipeline and a control pipeline. The air intake pipeline is provided with first and second filter decompressors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com