Wearing and clogging diagnosing method of SCR denitration catalyst

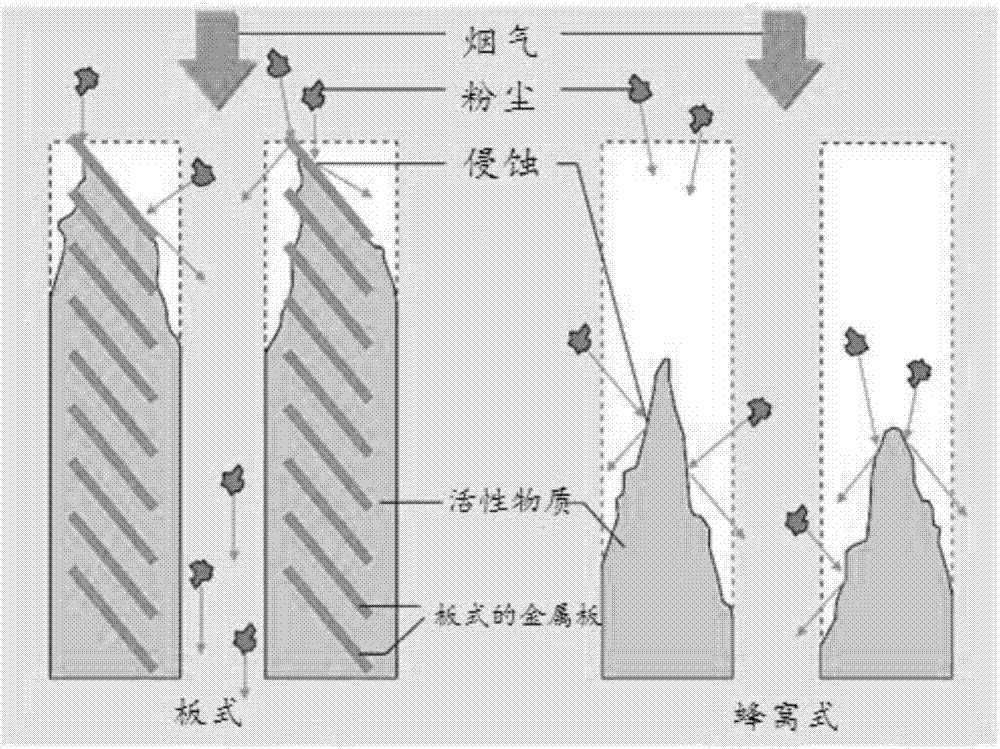

A denitration catalyst and diagnosis method technology, applied in the field of SCR denitration catalyst wear and ash blocking diagnosis, can solve problems such as perforation, denitration performance decline, shortening service life, etc., to reduce risks, improve operating economy and equipment safety, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

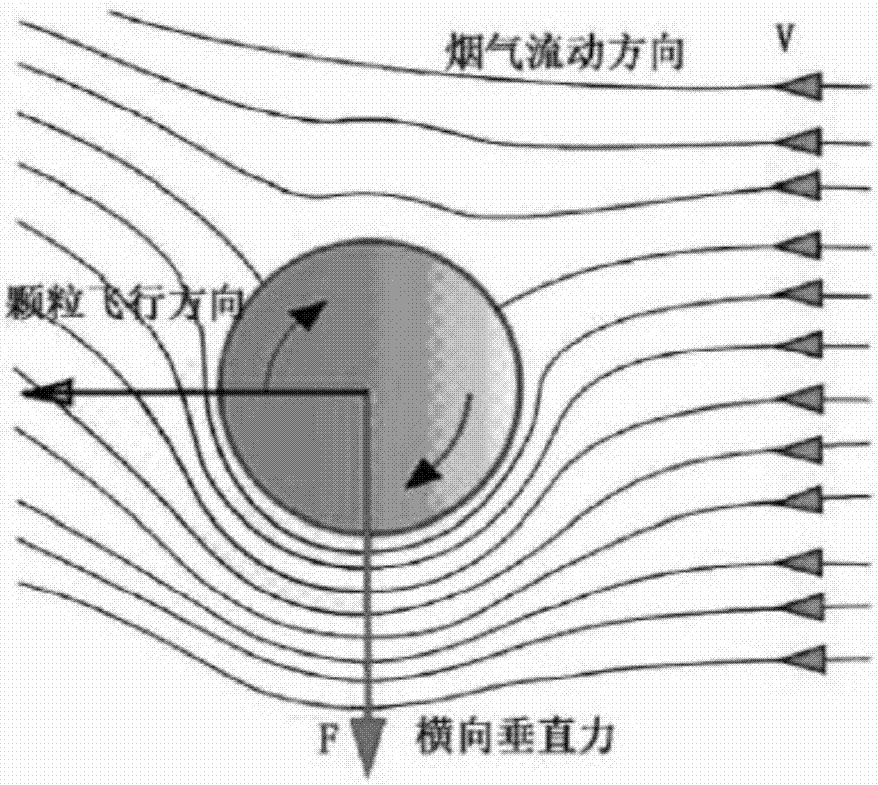

Problems solved by technology

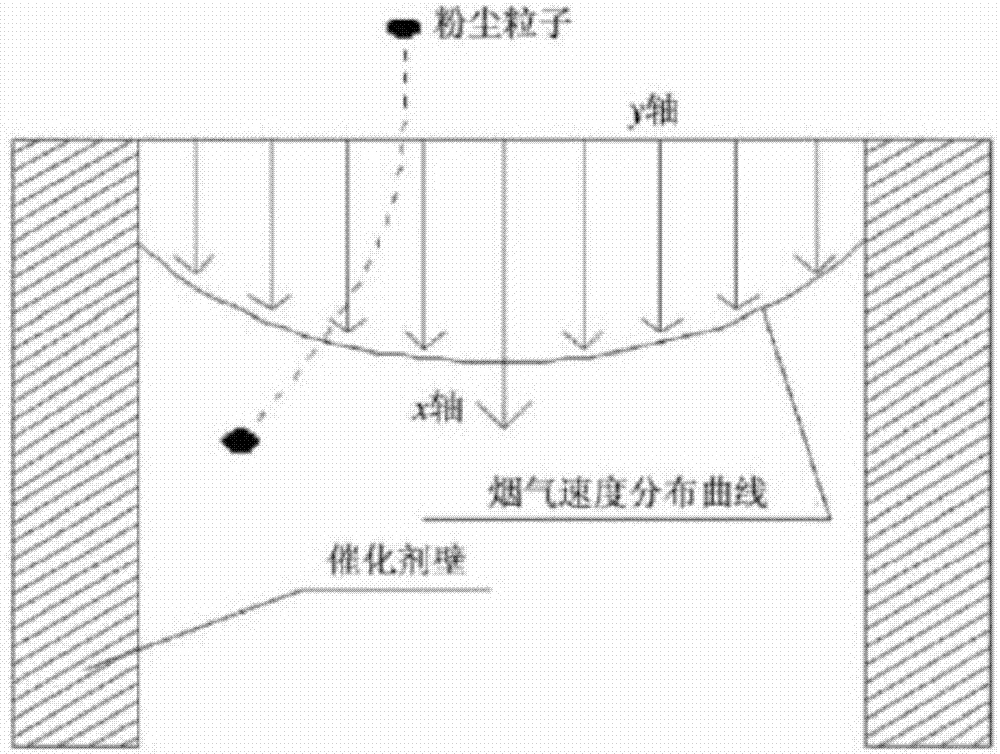

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0046] This embodiment introduces specific steps and solutions based on the analysis of the cause of SCR catalyst wear of a 300MW unit as an example. SCR denitrification catalyst wear and ash plugging diagnostic methods are as follows:

[0047]Firstly, the wear and ash blocking conditions of the catalyst inside the reactor are illustrated, marked and drawn into a visual cloud map, in which: the catalyst wear and ash blocking conditions include the occurrence area, occurrence form, severity, number and proportion of damaged units etc., and use a specific icon to mark the form of occurrence; use different shades of color to mark the severity; use different numbers to mark the number and proportion of damaged units.

[0048] Taking a 300MW unit as an example, it was put into operation in July 2013. The SCR reactor was arranged in a "2+1" arrangement. Two layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com